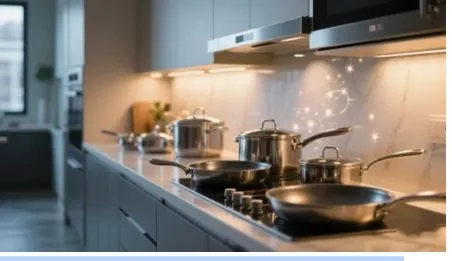

Cast Aluminum Cookware Safety Heat Distribution vs. Health Risks

Introduction: The Controversy and Market Reality

Walk into any kitchenware store, and you’ll likely encounter cast aluminum cookware—a popular choice for its lightweight design and exceptional heat conductivity. But the question on many minds is: Is cast aluminum cookware safe? This article aims to unravel the myths and facts surrounding this widely used kitchen essential, backed by scientific research and industry standards.

Cast aluminum cookware has been a staple in kitchens for decades, valued for its affordability and performance. However, concerns about aluminum leaching and coating safety have sparked debates. According to the World Health Organization (WHO), the average daily aluminum intake from cookware is minimal, but understanding the nuances of material science and usage practices is crucial for making informed decisions.

1. Scientific Analysis of Cast Aluminum Cookware Safety

1.1 The Truth About Aluminum Migration

Aluminum migration occurs when aluminum ions leach into food during cooking. However, modern manufacturing processes have significantly mitigated this risk. Hard anodized aluminum cookware, for example, undergoes an electrochemical process that forms a protective oxide layer, reducing aluminum migration to negligible levels (below 0.2mg/kg in pH 4-9 environments) .

Regulatory bodies like the FDA and EFSA emphasize that compliant cast aluminum cookware poses no significant health risks. In fact, daily aluminum intake from cookware typically accounts for less than 2% of the tolerable weekly intake set by health authorities .

1.2 The Dual Nature of Non-Stick Coatings

Non-stick coatings like PTFE (Teflon) and ceramic have transformed cooking convenience, but they come with caveats:

- PTFE Coatings: Stable below 260°C, but high heat can release toxic fumes. Scratches may also release microplastics .

- Ceramic Coatings: PFAS-free and heat-resistant up to 450°C, ceramic coatings are gaining popularity. In 2025, ceramic-coated cookware market share is projected to grow at a CAGR of 8.4%, driven by health-conscious consumers .

Leading brands like Calphalon and Cuisinart have phased out PFOA, ensuring safer alternatives for consumers .

1.3 Latest Positions from Regulatory Bodies

In 2025, the FDA issued a warning against certain imported cast aluminum cookware containing lead alloys like hind alium, highlighting the importance of choosing reputable brands . The EFSA reaffirmed that while aluminum exposure is not directly linked to Alzheimer’s disease, individuals with kidney issues should exercise caution .

2. Five Core Principles for Safe Use

2.1 Choose Quality Over Price

Look for hard anodized (Type III) or ceramic-coated products with FDA/EFSA certifications. Brands like Scanpan and Hawkins Cookers Limited are known for their rigorous quality standards . Avoid unregulated alloys like hind alium, which may contain lead .

2.2 Risk-Averse Cooking Techniques

Control heat levels: PTFE-coated pans should not exceed 260°C, while ceramic-coated pans can handle up to 400°C. Limit cooking acidic foods (e.g., tomatoes, vinegar) to 30 minutes and avoid long-term storage in aluminum cookware .

2.3 Maintenance and Lifespan Management

Clean with soft cloths and mild detergents; avoid abrasive tools. Inspect monthly for coating damage—replace pans immediately if scratches or peeling occur. Store in a dry place to prevent corrosion .

3. In-Depth Comparison with Other Materials

| Material | Pros | Cons | Best For |

| Cast Aluminum | Lightweight, excellent heat conductivity, affordable | Requires coating maintenance, not suitable for acidic foods in uncoated form | Everyday cooking, frying, baking |

| Stainless Steel | Non-reactive, durable, corrosion-resistant | Slow heat conduction, may develop hot spots | Acidic dishes, long-term storage |

| Cast Iron | Seasoned for natural non-stick, retains heat | Heavy, requires seasoning, prone to rust | High-heat cooking, oven use |

Cast aluminum’s heat conductivity is 3 times faster than stainless steel, making it ideal for quick-cooking methods like stir-frying. However, stainless steel remains the go-to for acidic recipes .

4. Common Questions and Misconceptions

Q: Does Cast Aluminum Cookware Cause Alzheimer’s Disease?

A: Extensive research, including studies by the Alzheimer’s Association, has found no direct link between aluminum exposure from cookware and Alzheimer’s. Aluminum in the brain is more likely from environmental factors or food additives .

Q: How to Check Coating Safety?

A: Look for third-party certifications like NSF or FDA. Use a magnet to test for stainless steel bases (non-magnetic), and avoid pans with visible cracks or peeling .

5. Sustainability and Future Trends

Cast aluminum is 100% recyclable, with a lower carbon footprint than stainless steel. Innovations like Plaslon, a PFAS-free plasma coating, are revolutionizing durability and sustainability . By 2030, ceramic coatings are expected to dominate 40% of the cookware market, driven by eco-conscious consumers .

Smart technology is another frontier: intelligent cast aluminum pans with built-in temperature sensors are emerging, offering real-time cooking feedback .

Conclusion: Make Informed Choices

Alu cookware is safe when used correctly. Opt for hard anodized or ceramic-coated products, follow heat guidelines, and prioritize reputable brands.

Remember: No cookware is entirely risk-free, but knowledge and mindful usage are your best defenses. Stay updated on industry trends and regulations to make choices that align with your health and sustainability goals.

Ready to Upgrade Your Cookware?

Explore our recommended cast aluminum cookware sets that combine safety, performance, and style. Shop now and elevate your cooking experience!

For those seeking professional-grade cookware solutions, Solamex stands out as a premier wholesale manufacturer specializing in cookware. Solamex offers an extensive product line including pots, pans, and wholesale grill skillet pan, and specialized cookware sets engineered for commercial kitchens and bulk purchasers. While primarily serving retailers and distributors, Solamex’s wholesale model provides significant cost advantages over consumer brands, delivering restaurant-quality performance at 30-50% lower price points without compromising on heat conductivity or coating integrity.