Expert PCB Design Services for Reliable and Innovative Electronic Solutions

In the rapidly evolving world of electronics, the demand for compact, efficient, and high-performance devices continues to soar. Whether it’s consumer electronics, industrial machinery, medical equipment, or IoT devices, a Printed Circuit Board (PCB) lies at the heart of every innovation. That’s where expert PCB design services come into play—ensuring your electronic products are reliable, scalable, and future-ready. From prototyping to production, investing in custom PCB design services is a strategic move for businesses aiming to lead in performance and innovation.

The Importance of PCB Design in Modern Electronics

The PCB is the backbone of any electronic device. It connects and supports electronic components using conductive tracks and signal traces, allowing the device to function as intended. But it’s more than just a wiring board—it’s a critical element that influences signal integrity, heat dissipation, mechanical strength, and overall product reliability.

A poor PCB design can lead to performance failures, electromagnetic interference, or even catastrophic product recalls. Conversely, a well-designed PCB optimizes space, minimizes costs, and enhances the end-user experience. This is why partnering with an expert in custom PCB design services is essential for companies that prioritize quality and innovation.

What Makes Expert PCB Design Services Stand Out?

When choosing a partner for PCB design, you don’t just need a vendor—you need a strategic collaborator. Expert PCB designers bring a wealth of experience, specialized tools, and industry insights that ensure every board layout aligns with your performance goals and technical constraints.

Key features that distinguish expert PCB design providers include:

- Tailored Customization

Every electronic project is unique. Whether you’re developing a wearable fitness tracker or an aerospace control system, off-the-shelf solutions rarely meet specific design criteria. That’s where custom pcb design services excel—providing personalized layouts based on your product’s form factor, electrical requirements, and application environment.

- Design for Manufacturability (DFM)

It’s not enough to create a design that works in theory. It must also be manufacturable at scale without defects. Expert PCB design services prioritize DFM principles to ensure the layout is optimized for production, reducing waste, cost, and assembly time.

- Advanced Simulation and Testing

Using powerful Electronic Design Automation (EDA) tools, top-tier PCB designers run simulations for signal integrity, thermal behavior, and power distribution before a single board is printed. These proactive measures identify issues early—saving time and resources down the line.

- Industry Compliance

High-reliability industries such as medical, automotive, and aerospace require strict compliance with international standards (e.g., IPC, ISO, MIL-SPEC). Expert design firms understand these requirements and ensure your design meets or exceeds regulatory expectations.

Advantages of Custom PCB Design Services

Opting for custom PCB design services offers a range of advantages that extend far beyond aesthetics or size optimization. Here’s how custom solutions can elevate your electronics project:

Optimized Performance

Custom PCB layouts allow for precise control over signal paths, component placement, and thermal zones. This optimization translates into better power efficiency, improved signal quality, and longer product life.

Cost-Efficiency Over Time

Although custom design may involve higher initial costs than standard PCBs, the investment pays off by reducing rework, improving manufacturability, and decreasing failure rates—ultimately saving money in mass production.

Faster Time to Market

Designing your PCB from scratch allows you to integrate only what you need, removing unnecessary complexity. Combined with agile development practices and simulation tools, this speeds up the design-prototype-iteration cycle.

Competitive Differentiation

A unique, high-performance PCB can become a key differentiator in your market segment. Custom designs empower you to innovate freely, break design limitations, and offer features your competitors can’t replicate easily.

Applications Across Industries

From startups to global OEMs, companies across industries rely on expert PCB design services to bring their electronic products to life. Some of the top sectors benefiting from custom PCB design include:

- Consumer Electronics: Smartphones, smartwatches, home automation systems

- Medical Devices: Portable monitors, diagnostic tools, implantable electronics

- Automotive: EV battery systems, ADAS modules, infotainment systems

- Industrial Automation: Control panels, robotics, IoT sensors

- Aerospace and Defense: Communication systems, flight controllers, mission-critical electronics

Each industry comes with its own set of challenges, from space limitations to harsh operating environments. A custom approach ensures your PCB meets these unique demands without compromise.

The PCB Design Process: From Concept to Reality

Partnering with a professional PCB design company typically follows a well-structured process:

- Requirement Analysis

This initial phase involves gathering all product specifications, including functionality, size constraints, input/output requirements, and environmental conditions.

- Schematic Design

Based on the requirements, engineers create a schematic diagram that defines the electrical connections and component relationships.

- PCB Layout Design

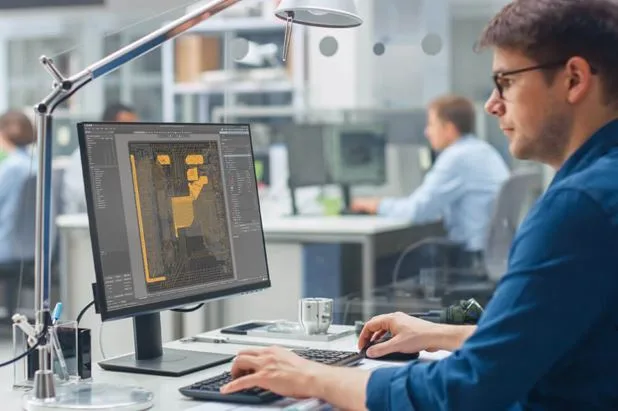

Using CAD tools, the schematic is translated into a physical board layout, placing components and routing copper traces according to electrical and mechanical rules.

- Simulation and Verification

Before fabrication, designers run simulations to test the board’s behavior under various conditions—checking for EMI, thermal hotspots, and signal delays.

- Prototyping

A physical prototype is manufactured and tested to validate the design in a real-world environment.

- Final Design and Production Handoff

Once validated, the design files are finalized, including Gerber files, BOM (Bill of Materials), and assembly drawings. These are handed off for full-scale production.

How to Choose the Right PCB Design Partner

Not all PCB designers are created equal. Here’s what to look for when selecting a provider for your custom PCB design services:

- Experience & Portfolio: Look for providers with proven expertise in your specific industry.

- Tool Proficiency: Ensure they use industry-standard tools like Altium Designer, OrCAD, Eagle, or KiCAD.

- Certifications: IPC membership, ISO 9001 certification, and RoHS compliance are good indicators of professionalism.

- End-to-End Services: A partner who offers both design and prototyping/fabrication simplifies your development cycle.

- Support & Communication: Clear timelines, regular updates, and responsive communication are vital for smooth project execution.

Future Trends in PCB Design

The world of PCB design is constantly evolving. Some key trends to watch include:

- Flexible and Rigid-Flex PCBs: For wearables and compact devices.

- High-Density Interconnect (HDI): Allowing more functionality in smaller footprints.

- AI-Assisted Design Tools: Using machine learning to optimize layouts faster.

- Green PCB Manufacturing: Eco-friendly materials and processes.

Staying updated on these trends and leveraging the right custom PCB design services ensures your business stays ahead of the technology curve.

Conclusion

In a digital landscape where innovation, speed, and reliability are the keys to success, your PCB design strategy can make or break your product. Whether you’re building a prototype or scaling to mass production, expert guidance ensures your project stays on track. By partnering with professionals who specialize in custom PCB design services, you gain access to precision engineering, industry expertise, and future-ready solutions that fuel your innovation journey.

Don’t let subpar PCB design hold back your electronics project. Invest in quality, customization, and collaboration—because great technology begins at the board level.