Perforated Metal Cladding Panels: Cost, Design Options, and Installation Tips

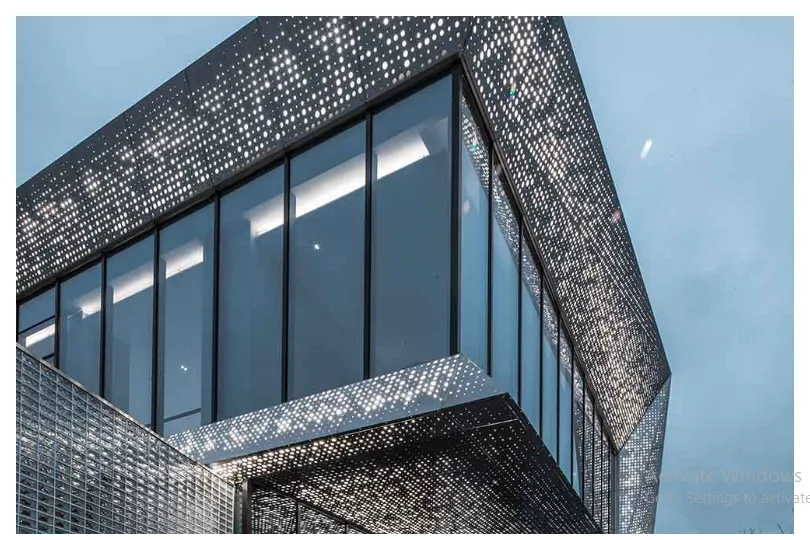

Perforated metal cladding panels can be useful in providing both useful and aesthetic value to modern architecture. They are highly preferred by architects since their designs are universal, can be ventilated, offer light, and other spectacular visual effects.

Such metal cladding panels are made up of robustness and aesthetic appeal, and a variety of designs, materials, and finishes. Perforated metal cladding enhances energy efficiency and acoustics in addition to aesthetics, both indoors and outdoors.

What Is Perforated Metal Cladding?

Metal cladding is made by perforating metal, and it assumes the shape of a perforated design that makes it convenient and attractive. They are mainly used on the exterior of buildings to offer ventilation, to control light, and to render the buildings appealing.

Perforated cladding is usually manufactured out of aluminum, stainless steel, or galvanized steel, and can be customized with respect to thickness, hole size, and pattern. This flexibility allows architects to design bold designs and be durable at the same time.

Benefits of Using Perforated Metal Panels

Perforated metal panels are built to be both functional and attractive. They enhance ventilation, distribution of light and sound, and provide creative freedom to architects to design facades with customizable patterns and distinctive visual effects.

Enhanced Ventilation

Perforated panels permit the movement of air in a space evenly, promote ventilation, and offer comfort. At the same time, they provide seclusion and safety, which implies that functionality and aesthetics of the inside are not compromised.

Light Control

Perforated metal panels are an agreeable sunscreen and capable of regulating the natural light into the interior areas. This reduces glare, gives more ease to the eyes, and a more favourable and harmonious ambience to the occupants daily.

Acoustic Performance

Noise levels in noisy areas are damped and deflected using perforated panels. This is a sound performance that enhances the comfort of occupants without affecting the open and aesthetically appealing architectural design in the whole space.

Durability

These panels are very resistant to corrosion, weathering, and general wear, thus ensuring that they are very effective in different climates. They are a dependable option regarding exterior and interior design of architecture because of their durability.

Design Flexibility

Accurate designs, forms, and finishes are an excellent contribution towards the appearance quality of metal cladding panels. They enable architects to design unique and lively fronts to integrate performance and beauty in contemporary buildings.

The perforated metal panels are used to enrich the interior and exterior space. Their versatility and design capability can offer handy solutions that have a fine design that may be quite practical but aesthetically challenging in contemporary architecture.

Types of Perforation Patterns

Perforated patterns identify the functionality and appeal of metal cladding panels. Positioned variable holes, sizes, and distances permit the architect to control the light, air flow, and appearance in order to create both practical and good-looking facades.

Round Holes

This is a common and very variable solution, and would have endless architectural applications. It is the best possible solution for ventilation, the handling of natural light, and the creation of a comfortable balance between functionality and aesthetics.

Square or Rectangular Holes

Square or rectangular punched holes create a clean and modern geometric style. They provide a confident, contemporary architectural character, which complements facades where symmetry, form, and a very modern expression of form are key.

Slotted Patterns

The patterns are optimized for maximum air flow efficiency, but also maximum sound absorption. At the same time, they are characterized by a modern and simple appearance that fits very well with functional requirements and architectural style.

Custom Shapes

You may also add custom perforations to add logos, symbols, or artistically patterned perforations. These designs include special, branded fronts, which express identity more than the addition of aesthetic and functionality to architectural designs.

This method of perforation was a way of showing how effective and attractive metal cladding panels were. The light, air flow, and look can be manipulated by putting variable holes, sizes, and distances to create practical and attractive facades.

Materials for Perforated Metal Cladding

Facade projects demand proper material choice to provide durability, performance, and beauty to the project. The dissimilar metals come in different strengths; hence, they can be used in different environments, design styles, and applications.

Aluminum

The aluminum is lightweight, resistant to corrosion, and simple to produce. These features allow them to be an adequate material choice in the modern facades that harmonize permanence and accommodation in construction and architecture.

Stainless Steel

It is strong and stable and is not affected by rust, corrosion, or extreme weather. This is well fit and appropriate because strength is the first requirement before its application occurs in the huge architectural buildings within different conditions.

Galvanized Steel

These are cheaper and extremely durable panels having shielding finishes that increase their lifespan. They are not only a good selection in practical and cost-effective architectural use, but also give good strength with average corrosion resistance.

Copper or Brass

It contains its own color tones and acquires a natural patina with time. It is also generally a form of ornament and part of the development of character, of a lovely appearance, and of the continuity of the aesthetic value of the architectural objects.

The correct selection of the material guarantees durability and efficiency, and will boost the aesthetics. Designers can invest in quality metals to have maximum benefits of perforated metal cladding, resulting in both practical and aesthetic results.

Aluminum Facade Cladding: A Popular Choice

The aluminum panels, non-corrosive, lightweight, and easily designed, are the most popular facade & cladding in modern architecture. These have both practical and aesthetic merits, and are therefore appropriate to the exterior of modern buildings.

Lightweight

Aluminum cladding is incredibly light, and this is what makes a building structurally lightweight and amazingly so. It also installs easily; it can be installed fast, effortlessly, with less effort and less expense, and gives good performance and durability.

Corrosion Resistant

It gives us a good working capability during various weather conditions, and it does not lose power or its appearance. It is rust and corrosion-resistant, durable, and therefore suitable for long-term facade applications in a variety of environments.

Design Flexibility

It is versatile in its design because it allows a wide range of finishes and color options. It is an added advantage to the architectural ingenuity that there are so many perforation patterns out there, as well as making sure it functions and is pretty.

Sustainable

The aluminum cladding panels are highly recyclable, their impact on the environment is minimal, and it is easier to maintain. They too are green and hence, very suitable in the new day architecture, both in design and responsible building.

Durable

It retains the power along with aesthetics in a life cycle. They are made with maintenance and quality materials so that these panels do not cease to do the work that they are supposed to do, and they also have the same original appearance.

These attractive, powerful, and sustainable aluminum panels provide designers with choices to be inventive in developing appealing building facades. Aluminum facade cladding is applicable in building construction projects because of its versatility.

Cost Considerations for Perforated Panels

Perforated metal panels can be priced based on the budget that informs the design of a useful facade. Price is based on the material, size of the panel, complexity of the holes, as well as other finishes, which define the cost, and in the long-term value.

Material Type

The influence of the aluminum, stainless steel, and copper on cost in general is ambivalent. Aluminum is usually cheaper than stainless steel, and copper can, at times, cause the project to change in terms of strength, life span, and general appearance.

Panel Thickness

The stronger, more stable, and longer-lasting panel is what makes thicker panels more appropriate in an impactful project. But they eat more raw material and machine and are consequently much more expensive than other, thinner ones.

Perforation Design

Complex perforation has more complicated styles of perforation that require more materials and machinery to produce. The increased level of detail and exactness demanded can also increase the cost over less difficult, more common panel designs.

Finishes and Coatings

More costs are added by powder coating, anodizing, and special finishes. The custom color selection also affects the product pricing since it requires more processes to achieve lasting and beautiful finishes, depending on the design requirements.

Installation Expenses

The key influences on the overall costs of the project are the building specifications, workforce cost, and hardware cost. Submission of such considerations will help to effectively budget and install perforated metal panel systems that are cheap.

These dimensions would also enable the designers and the project managers to trade quality and budget. Perforated panels are designed intelligently to provide practical performance and attractiveness without the unproductive use of resources.

Customization and Design Options

The base price of perforated panels depends a lot on the material type. Every aluminum, stainless steel, or copper has different price tags, life cycles, and fabrication requirements, which influence budget planning and overall investment in a project.

Patterns and Shapes

The most common variations of perforation are round, square, and slotted, but functionality and style variants exist as well. Logos may also be contracted in such a way that they bring in a higher level of creativity and may be labeled under their brand.

Finishes

A protective coating from anodizing, powder coating, and PVD coating increases durability. The treatments also improve aesthetics and give architects and designers flexible options where modern, robust, and beautiful facades are concerned.

Colors

A rich variety of colors boosts architectural creativity and goes well with different sorts of building styles. Color selections allow architects to achieve powerful visual statements while complying with the existing material and spatial conditions.

Panel Sizes and Layouts

Cladding panel sizes can be customized to fit project sizes to create smooth fits in a variety of architectural uses. Customized sizes complement the functionality and visual harmony of modern building designs through compliance with facade geometry.

Texture Effects

Textures and depth are added to panels through brushed, perforated, or embossed finishes. These finishing options allow architects and designers to incorporate aesthetic effects, but in a practical and enduring way, in modern architectural designs.

An analysis of these opportunities will allow the architects to improve functionality and beauty. Careful tailoring makes every perforated metal panel design project-specific and provides a high-performance and attractive facade of high visual appeal.

Choosing a Manufacturer and Fabricator

High-quality perforated metal cladding panel production requires the choice of a manufacturer and fabricator. The success of a facade project depends on the success of an accurate, stable, and uniform production performed by the appropriate partner.

Experience and Expertise

Find a company that has a lot of experience in cladding manufacturing so that the quality and results will be the same. An excellent history of performance indicates that they can execute challenging architectural practices and project specifications.

Material Capabilities

Make sure that the fabrication company can handle your finishes and metals of choice. Guarantee of this capacity affords the panels with design specification, with no effect on quality or durability, and the appearance you want on your project.

Customization Options

The cladding can come up with its own perforation patterns and panel sizes that may fit a particular building design. The freedom enables the architects to generate new forms of aesthetics without affecting functionality and structural integrity.

Quality Control

This should be checked and experimented with thoroughly to ensure that everything in the panels is of good quality. This provides durability, correct size, and stability to the performance of long-lasting, complete quality perforated cladding installations.

Installation Support

They either offer professional advice or practical support to ensure that they do proper panel mounting. Structural integrity, durability, and the intended aesthetic appearance of the facade can be preserved when installed and in good alignment.

Working with a skilled manufacturer ensures that your project design, performance, and budget will be met. The credible fabricator will provide quality output and convert architectural dreams to sustainable, attractively designed building facades.

Conclusion

Perforated metal cladding provides architects with design flexibility, functionality, and durability. Designers can produce aesthetically appealing, sturdy facades that are both beautiful and efficient through the use of material, pattern, cost, and installation.