The Dual Bearing Revolution: How the IKAPE Double Bearing Coffee Distributor Redefines Espresso Prep Standards

In the pursuit of exceptional flavor in the specialty coffee world, espresso is often regarded as the crown jewel. Its creation is a precise science and a complex art. Every minor variable—the freshness of the beans, the grind size, water temperature, water pressure, and even the pressure applied during tamping—ultimately manifests in that small cup of rich liquid.

In the past, baristas focused most of their attention on grinders and espresso machines. However, in recent years, a critical preparatory step has gained increasing importance: the even distribution and leveling of the coffee grounds (Puck Preparation). In this revolution of prep workflow, the IKAPE Double Bearing Coffee Distributor has become a focal point in the industry, thanks to its groundbreaking engineering design and exceptional performance.

The Limitations of Traditional Distributors: Why Do We Need a Change?

To understand the innovative nature of the double bearing distributor, we must first examine the inherent flaws of traditional distributors.

Unibody Rotation and Frictional Resistance

Traditional gravity-based or gear-type espresso distributors often rotate as a single unit. This means that the force applied by the user must not only be used to rotate the bottom blades to level the coffee grounds but also to overcome the significant static and kinetic friction between the entire distributor body and the rim of the portafilter basket. This resistance leads to uneven rotation, requires more effort, and may even cause the entire portafilter basket to rotate if force is applied unevenly. It can also create uncontrolled lateral pressure within the coffee bed, disrupting the uniformity of the coffee layer.

Sole Reliance on Gravity Distributor

Traditional coffee distributors rely entirely on their own weight to sit on the coffee grounds. Their height is usually pre-set, meaning they can only “float” on the surface of the grounds, performing a passive leveling action with almost no active, slight downward pre-tamping effect. For different doses of coffee, the results are inconsistent.

Design Flaws Leading to Grounds Disturbance

The bottom blades of many traditional distributors are relatively simple, often featuring 3 or 4 flat surfaces. This design, when rotating, especially counterclockwise, tends to push coffee grounds upward or trap them between the blades rather than combing them smoothly. This can actually disrupt the uniformity already achieved by a WDT tool, creating new density inconsistencies.

It was these pain points that spurred the demand for the next generation of distributor technology. The IKAPE Double Bearing Distributor is precisely engineered to address each of these issues with targeted optimizations.

Core Innovation #1: Dual Bearing Structure – The Engineering Secret Behind Silky Smooth Rotation

“Double Bearing” is the core keyword of this product and the physical foundation of all its exceptional performance.

IKAPE team innovatively integrated a dual precision bearing structure within a unibody housing. This means that when the user grips the handle and rotates it, the applied torque is transmitted almost losslessly and seamlessly to the bottom distribution plate via the bearings. The entire aluminum alloy outer shell remains relatively stationary or moves only minimally.

Revolutionary Experience Delivered

Ultra Effortless and Silky Smooth

The dual bearings drastically reduce the torque required for rotation. Users need only a light flick of a finger to set the distribution plate spinning smoothly and rapidly like a top. This silkiness completely eliminates the stiff, jerky operation of traditional distributors.

Absolute Levelness and Stability

Freed from significant frictional interference, the distributor sits stably on the rim of the portafilter basket, ensuring the distribution plate remains perfectly parallel to the basket at all times. The rotation process involves no tilting or wobbling, guaranteeing that the combing force applied to every part of the coffee grounds is completely consistent.

Protects Coffee Bed Structure

The gentle rotation avoids any potential squeezing or disturbance to the coffee grounds caused by excessive force, perfectly preserving the uniform structure created by WDT and laying the most ideal foundation for the subsequent tamping step.

Core Innovation #2: Magnetic Levitation Balance Ring—The Revolution in Precise and Controllable Pre-Tamping

If the dual bearings solve the “rotation” problem, the magnetic levitation balance ring solves the issue of depth control.

Unlike traditional coffee distributors that rely solely on gravity, IKAPE embedded powerful magnets within the balance ring. Utilizing the principle of magnetic repulsion between like poles, it creates a unique “magnetic levitation” tactile feedback. When you press the distributor downward, you feel a clear, linear, and gentle magnetic pushback.

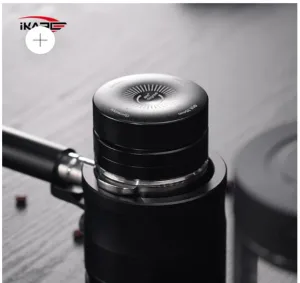

(IKAPE Double Bearing Coffee Distributor)

Revolutionary Experience Delivered

Active Pre-Tamping

This design allows the user to apply a slight, controllable downward pressure. The magnetic repulsion evenly feeds this pressure back to the coffee bed, achieving a gentle and uniform pre-compression of the puck. This step effectively eliminates minor voids remaining in the coffee bed after WDT, making the puck density preliminarily more consistent and avoiding potential density stratification that might occur from subsequent forceful tamping.

Prevents “Seizing” Effect

Traditional distributors, if pressed too deep, can tightly “seat” themselves on the grounds, making them difficult to lift or causing disruption to the coffee surface upon removal. The rebound force provided by the magnetic levitation balance ring ensures the distributor can always disengage cleanly and easily from the grounds.

Enhanced Adaptability

Whether your dose is 18g, 20g, or 22g, you can intuitively control the distribution depth through the tactile magnetic feedback, ensuring a consistent pre-tamping effect every time, greatly improving shot consistency.

Core Innovation #3: Nine-Sided Distribution Plate—Impeccable Final Leveling

After achieving smooth rotation and precise pre-tamping, the final result is determined by the distribution plate that directly contacts the coffee. IKAPE has deeply optimized this component.

This distributor features a meticulously calculated and CNC-machined new 9-sided distribution plate base. This multi-faceted, multi-angled complex design ensures that the efficiency and effectiveness of combing the coffee grounds are identical whether rotating clockwise or counterclockwise.

Revolutionary Experience Delivered

Ultimate Flatness

More blade surfaces mean a finer, more continuous combing action, capable of creating an extremely flat and uniform coffee surface without any ridges or marks.

Bidirectional Freedom

Completely solves the problem of grounds catching or being pushed by traditional 3 or 4-blade distributors when rotating in reverse. You can now freely choose your rotation direction with identical results.

Non-Stick Design

The smooth food-grade 304 stainless steel surface, combined with the optimized geometry, means coffee grounds hardly stick to the distribution plate, making cleaning exceptionally simple.

(IKAPE V6 impact coffee tamper and double bearing coffee distributor)

Food-Grade Safety and Daily Maintenance

IKAPE makes no compromises on material selection. The main structure uses lightweight yet robust aluminum alloy, while all parts contacting coffee grounds—the distribution plate and base—are made from food-grade 304 stainless steel. This material is not only safe, non-toxic, and corrosion-resistant but also hard and smooth-surfaced, making it very easy to clean. A simple rinse with water restores it to a like-new state, and it may even be dishwasher safe (recommended to check the manual for confirmation), significantly enhancing daily usability.

Building the Perfect Extraction Workflow: Synergy with the IKAPE Impact Tamper

The IKAPE Double Bearing Coffee Distributor plays a crucial role, bridging the steps in the workflow. It takes the uniform distribution created by the WDT tool and solidifies it, pre-tamping it into an extremely level surface. This perfect surface is precisely prepared for the final tamping step.

Therefore, IKAPE recommends using it in conjunction with the IKAPE Impact Coffee Tamper. Such tampers often feature self-leveling and constant force impact mechanisms. When the distributor provides an impeccable level base, the impact tamper can perform the tamp at a perfectly vertical angle and with consistent force, ultimately resulting in a coffee puck with uniform density throughout.

Such a puck offers even resistance to water passing through, effectively preventing “channeling”—where water finds paths of least resistance through weak spots in the puck, causing some grounds to over-extract while others under-extract. The final result is a perfectly extracted espresso: uniform, with clear flavor layers, pronounced sweetness, and devoid of any negative off-flavors.

Conclusion

The IKAPE Double Bearing Coffee Distributor is far from a simple marketing gimmick. It is a professional tool born from a deep understanding of baristas’ daily operational challenges, realized through three core engineering innovations: the dual bearing structure, the magnetic levitation balance ring, and the nine-sided distribution plate. It comprehensively surpasses traditional distributors across four dimensions: effort reduction, stability, control, and levelness, elevating the repeatability and precision of coffee puck preparation to an unprecedented level.

For home coffee enthusiasts, investing in such a IKAPE espresso tool means fewer variables each time you make coffee and significantly higher consistency, greatly increasing your success rate in replicating cafe-quality beverages. It is not merely a tool but a reliable partner on your journey to becoming a specialty coffee master, helping you consistently extract that ideal, flawless shot of espresso.