DTF Printer vs. Sublimation Printer: Procolored.eu’s Hybrid Vision

In the evolving world of garment decoration, DTF printer and sublimation printer technologies each offer unique benefits—and at Procolored.eu, the goal is to bridge flexibility, quality, and usability for creative businesses.

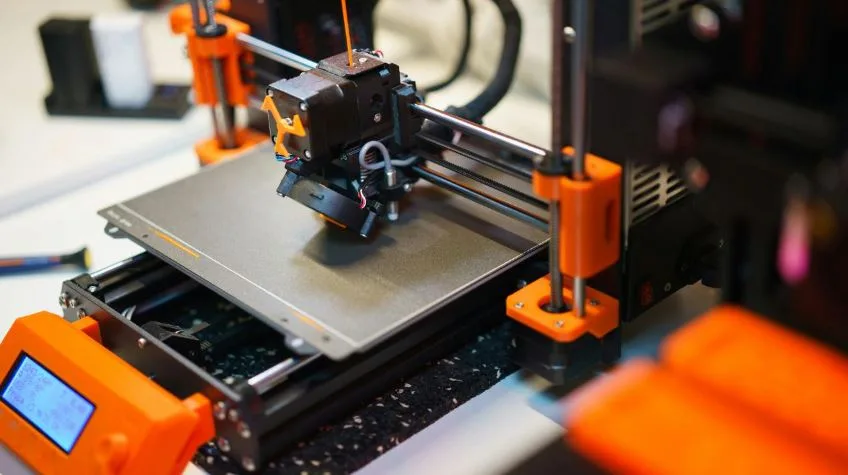

A DTF (Direct-to-Film) printer prints CMYK + white ink onto a PET transfer film, applies adhesive powder, cures it, and heat-presses the design onto fabric. This method works well on a wide range of textiles, including cotton, poly blends, and dark garments, without needing pretreatment.

Procolored’s K series models, for example, incorporate automatic cleaning, white‐ink circulation, and film cutting—making batch production more efficient and reliable.

On the other hand, a sublimation printer transfers dye onto polyester or specially coated substrates via heat, turning the ink into gas and embedding it into the fibers. It yields vibrant, permanent prints—but is typically limited to light, polyester fabrics or coated items like mugs and metal sheets

What sets Procolored.eu apart is how its product mix and vision reflect both technologies’ strengths. While DTF is a core focus, Procolored also offers UV DTF / UV printers suited for hard and coated substrates, broadening the creative scope beyond textiles.

This hybrid approach enables design studios, apparel brands, and print shops to expand into merch, promotional goods, or specialty items—all within the same Procolored ecosystem.

In summary, if your goal is full-color printing on various fabrics—especially dark or blend garments—DTF printers from Procolored give you versatility and strong results. If you work primarily with polyester or coated products, sublimation (or UV hybrid) methods have a place—though Procolored emphasizes DTF + UV pathways to give you more flexibility.

Visit Procolored.eu today to explore how their printer solutions blend DTF and sublimation (via UV methods) to power your creative business.