How Do Classic Denim Shirts and Heat Pressing Machines Work Together in Modern Apparel Production?

Denim has remained an enduring fabric in the fashion industry for decades, with the classic denim shirt holding a particularly iconic status. Meanwhile, the technological progress in the industry of apparel manufacturing has changed the process of clothes designing, customization, and finishing. Among these innovations, the heat pressing machine plays a pivotal role in enhancing both the aesthetic and functional qualities of denim apparel.

In this article, we will discuss how classic denim shirts and heat pressing machines intersect in modern garment production. We will explore how this combination enables manufacturers to meet quality expectations, offer customization options, and maintain consistency across large-scale operations.

So what are you waiting for? Let’s begin with our article!

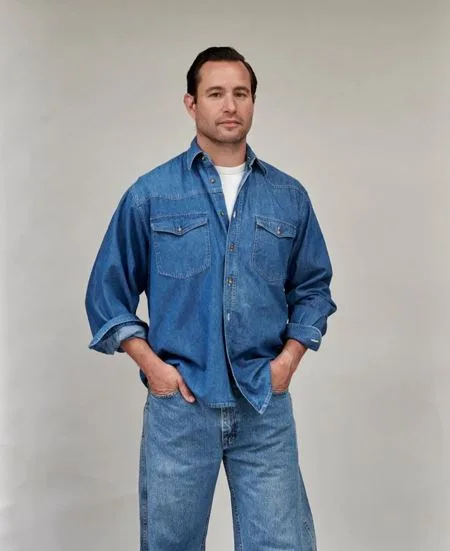

The Enduring Appeal of the Classic Denim Shirt:

The classic denim shirt has maintained popularity across generations due to its durability, comfort, and versatile style. Classically constructed out of durable cotton twill, it is a hybrid between casual and formal design. It has a wide market, both in workwear and fashion-forward lines.

The shirts have a particular character because of the texture and wash patterns of denim. Yet, to be able to ensure quality in the denim shirts, especially in large quantities, the processing of fabrics, stitching, and finishing methods should be carefully regulated. This is where technology, including heat pressing machines, integrates into the manufacturing process to enhance results and improve efficiency.

Denim is a very strong fabric and therefore finishing procedures should be accurate without destroying the fabric yet producing a finished product. As another example, denim shirts can be finished with special pressing to get sharp lines, correct shapes and control the crease, particularly prior to reaching retail presentation, after initial assembly.

The Role of Heat Pressing Machines in Apparel Production:

A heat pressing machine applies controlled heat and pressure to fabrics for various purposes, such as setting creases, bonding decorative elements, or applying heat transfers. These machines can be applied in the apparel industry not only in order to accomplish the functional finishing but also to make clothing branded, labeled or decorated with special decorative details.

In denim shirt production, heat pressing machines can serve several purposes. It is also used in the making of fine finishing to collars, cuffs and seams so that all units in a production batch look the same. Heat is also used to help determine the shape of the fabric, especially in regions where the natural stiffness of denim might be impervious to the standard pressing techniques.

For customization, heat pressing machines are integral in applying patches, logos, or printed designs directly to denim surfaces. This allows manufacturers to diversify product lines without changing the core construction of the garment, appealing to both mass-market and niche audiences.

Integrating Heat Pressing in Denim Shirt Customization:

One of the most significant intersections between the classic denim shirt and heat pressing technology lies in personalization. The current consumers are more interested in customized garments to express their personal taste, and heat pressing offers a quick and cheap method of creating such attire.

The manufacturers are able to print complex patterns, logos or branding on denim through heat transfer vinyl (HTV) or sublimation, and the process does not weaken the fabric. Properly applied, these applications resist repeated washings and wear, which is vital in the preservation of the premium appearance of the garment over its life.

For example, a fashion brand may offer limited-edition classic denim shirts featuring custom graphics or seasonal designs. Using heat pressing machines, these designs can be applied in small or large batches with minimal lead time, giving brands flexibility in responding to market trends.

Moreover, the functional elements can be applied directly to the inside of the shirt by heat pressing, e.g. care labels or size markings without the need to use sewn-in tags. This does not only make it more comfortable to the wearer but also cuts down on the manufacturing processes.

Ensuring Quality and Consistency Across Production:

Creativity is not the only thing that is important in high-volume production of denim shirts. Differences in finishing, print alignment or shaping of the fabric can compromise brand reputation. Heat pressing machines help address these challenges by delivering precise and repeatable results across every garment in a batch.

Modern heat pressing machines are equipped with digital controls for temperature, pressure, and pressing time, allowing operators to set exact parameters based on the denim’s weight and treatment. These controls ensure that every classic denim shirt receives the same level of finishing, whether it is pressed to sharpen its silhouette or decorated with a brand logo.

In addition, the use of specialized pressing plates and protective sheets prevents scorching or discoloration of the fabric—an important consideration given denim’s natural tendency to develop color variations during high-heat processes. This ensures the shirt’s original dye finish remains intact while achieving the desired final appearance.

Cross-Sector Lessons Between Fashion and Equipment Manufacturing:

The relationship between the classic denim shirt and heat pressing machines highlights a broader synergy between fashion design and industrial equipment innovation. While fashion brands focus on style, fit, and trend alignment, heat pressing machine manufacturers concentrate on precision engineering, reliability, and operator-friendly controls.

The partnerships between equipment suppliers and apparel manufacturers usually result in machine adjustments that are more suited to a particular material or process. In the case of denim shirts this could be special pressing plates to fit the panels on a shirt more effectively, or pressure adjustments to different denim weights.

The above developments do not only improve the production of denim shirts, but they also improve the pressing technology of other garments categories. In the same way, the needs of the fashion industry regarding speed, customization, and sustainability force new innovations in heat pressing equipment.

Conclusion:

The connection between the classic denim shirt and the heat pressing machine demonstrates how tradition and technology can work together to deliver both quality and creative flexibility. We have talked in this article about how the classic allure of denim shirts intersects with the accuracy and effectiveness of heat pressing machinery. By combining the durability and style of denim with the customization and finishing capabilities of modern heat pressing machines, manufacturers can offer products that meet contemporary consumer expectations while maintaining consistent quality.