Find Phone Case Suppliers for Innovative Brand Logo Display

Over 6.8 billion people worldwide use smartphones daily, making mobile devices the most consistent touchpoint between brands and consumers. Yet while 78% of marketing professionals recognize promotional products drive brand recall, most struggle to break through the noise of generic giveaways. Phone cases represent a unique opportunity—they’re protective necessities that transform into walking billboards, visible during the average person’s 58 daily phone checks. The challenge isn’t whether to use phone cases for branding, but finding suppliers who can elevate your logo beyond faded prints that chip after weeks of use. Standard screen printing and basic decals fail to convey premium brand values, leaving marketing teams searching for manufacturing partners who understand that logo display quality directly impacts brand perception. This article reveals how to identify suppliers offering cutting-edge branding technologies, particularly In-Mold Labeling (IML), that ensure your logo remains vibrant and scratch-resistant throughout the case’s lifespan. You’ll discover evaluation frameworks for vetting manufacturers, emerging display innovations, and strategic design approaches that maximize every impression your branded case makes.

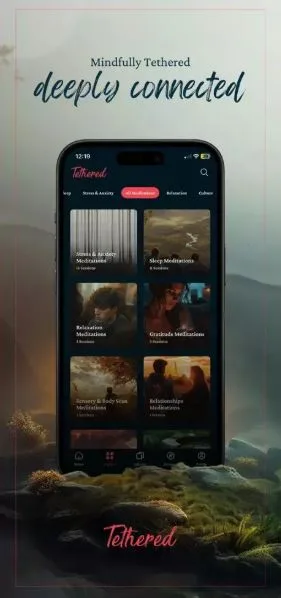

Why Phone Cases Dominate Promotional Branding

Research indicates that 79% of smartphone users purchase protective cases within the first month of device ownership, creating an immediate opportunity for brand visibility. Unlike business cards tucked into wallets or pens left in drawers, phone cases accompany users through approximately 4.8 hours of daily screen time and countless social interactions. This constant physical presence translates to repeated brand impressions—studies show promotional products generate 500% more referrals than print advertisements, with phone cases leading retention rates due to their functional necessity. Traditional promotional items like keychains or USB drives offer limited surface area and infrequent visibility, while phone cases provide premium real estate that’s displayed during meetings, commutes, and social media content creation. The financial advantage becomes clear when calculating cost-per-impression: a $5 phone case used daily for two years delivers brand exposure at approximately $0.007 per day, compared to digital ads costing $2-15 per thousand impressions. Durability amplifies this ROI—quality cases maintain logo integrity through thousands of pocket insertions and surface contacts, ensuring your brand message doesn’t fade when users need reliability most. This longevity positions phone cases as infrastructure investments rather than disposable marketing collateral, building subconscious brand associations through consistent, tactile engagement.

Essential Features in Top Phone Case Suppliers

Criteria for Brand-Centric Manufacturing

Minimum order quantities reveal a supplier’s flexibility for campaign testing—seek manufacturers offering runs starting at 100-500 units rather than requiring 10,000-piece commitments that strain budgets and warehouse space. Material selection directly communicates brand positioning: polycarbonate blends signal durability for tech brands, while biodegradable TPU aligns with sustainability-focused companies. Production timelines become critical when coordinating product launches or seasonal campaigns; reliable suppliers complete custom orders within 15-25 days, providing buffer time for quality checks before distribution deadlines. Certifications like ISO 14001 environmental management or FSC material sourcing aren’t just compliance checkboxes—they’re storytelling tools that reinforce brand values when customers examine case packaging. Request material safety data sheets and factory audit reports upfront; suppliers hesitant to share documentation often cut corners that eventually surface as quality failures during your campaign.

Custom Branding Capabilities Assessment

Compare logo integration methods by requesting sample cases using screen printing, pad printing, laser engraving, and IML side-by-side—the tactile differences immediately reveal which techniques match your brand’s quality standards. Color matching technology separates professional suppliers from generic manufacturers; Pantone matching systems ensure your logo’s specific shade transfers accurately across production batches, preventing the brand dilution caused by inconsistent hues. Prototyping services should include physical samples within 5-7 days, allowing your team to test logo visibility under various lighting conditions and assess how designs interact with phone camera cutouts or button placements. Evaluate whether suppliers offer dedicated design consultation—manufacturers with in-house graphic teams can optimize logo sizing and placement based on case geometry, preventing common mistakes like logos obscured by users’ natural grip positions or distorted across curved edges.

Innovative Technologies for Logo Display

IML Technology: Revolutionizing Branded Phone Cases

In-Mold Labeling fuses printed films directly into case materials during injection molding, embedding logos beneath protective polymer layers that resist scratches, UV degradation, and chemical exposure. Unlike UV printing where inks sit atop surfaces vulnerable to abrasion, IML integrates graphics into the case structure itself—testing shows IML logos retain 95% clarity after 50,000 simulated pocket cycles, compared to 60% retention for screen-printed alternatives. A beverage company switching from pad printing to IML reported 40% higher brand recall in consumer surveys, attributing gains to logos maintaining factory-fresh vibrancy throughout the case’s lifespan. The technology accommodates intricate designs including gradients, photographic elements, and fine text below 6-point sizes that traditional methods blur or omit. Manufacturers like runsun case have adopted IML processes that create seamless finishes eliminating raised edges where dirt accumulates, ensuring logos remain legible rather than obscured by debris trapped around printed borders.

Beyond IML: Emerging Branding Methods

3D lenticular printing creates motion effects where logos shift between two images as viewing angles change—tech startups use this to alternate between brand marks and product visuals during natural phone handling. Photoluminescent inks absorb ambient light and glow for 4-6 hours, making logos visible in darkened environments like theaters or evening events where standard cases disappear. Textured UV coatings add tactile dimensions, letting users feel embossed logos through soft-touch finishes that communicate premium positioning through haptic feedback. Mycelium-based biodegradable cases now accept water-based dye sublimation, allowing eco-conscious brands to showcase sustainability commitments through both material choice and chemical-free branding processes. Hybrid approaches combine IML base layers with secondary laser engraving, creating depth contrasts where matte-etched elements highlight glossy embedded graphics for architectural logo presentations that shift under changing light.

Step-by-Step Supplier Evaluation Process

Begin by exploring specialized B2B directories like Global Sources and Alibaba’s verified manufacturer sections, filtering for suppliers with “custom branding” and “promotional products” certifications rather than generic case listings. Trade shows such as the Hong Kong Electronics Fair or PPAI Expo provide face-to-face equipment inspections—observe whether suppliers demonstrate IML machines or only display finished samples, revealing actual manufacturing capabilities versus reseller operations. Create a technical checklist requiring suppliers to document sample turnaround times under 7 days, machinery specifications including injection molding tonnage and printing resolution capabilities, and quality control protocols with defect rate thresholds below 2%. Analyze portfolios specifically for logo-centric projects rather than generic product shots; request client references from brands in your industry to verify color accuracy maintenance across large production runs. Test scalability through pilot orders of 200-500 units before committing to bulk contracts—monitor whether quality consistency holds and communication responsiveness remains intact under deadline pressure. Verify compliance documentation including trademark infringement insurance coverage, RoHS material certifications for international distribution, and drop-test reports meeting military-grade protection standards that enhance your brand’s reliability narrative. Request non-disclosure agreements before sharing proprietary logos, ensuring suppliers maintain confidentiality protocols that protect your design investments throughout the evaluation process and beyond contract signing.

Maximizing Brand Impact Through Design Choices

Position logos in the upper third of case backs where they remain visible when phones rest on tables, avoiding lower quadrants obscured by wireless charging pads or grip positions during video recording. Color selection extends beyond matching brand guidelines—matte black cases with metallic silver logos convey tech sophistication, while pastel cases with tonal embossing appeal to lifestyle brands targeting wellness communities. Strike visibility balance by sizing logos at 15-20% of total case surface area; smaller marks risk invisibility in social media backgrounds, while oversized branding triggers promotional fatigue that discourages daily use. Trend-responsive elements like holographic finishes attract Gen Z audiences but risk appearing dated within 18 months, whereas classic debossed monograms maintain relevance across product cycles. A fitness app company increased user-generated content by 65% after redesigning cases with subtle logo watermarks that photographed well against gym equipment, proving restraint often amplifies organic brand advocacy more effectively than bold declarations.

Selecting the Right Partner for Branded Phone Cases

The right phone case suppliers transforms everyday accessories into strategic brand infrastructure that compounds visibility with every user interaction. While countless manufacturers offer basic printing services, suppliers equipped with IML technology and emerging branding methods deliver logo displays that withstand years of handling without fading—a critical advantage when each case generates thousands of micro-impressions across its lifespan. Your selection checklist should prioritize three non-negotiables: verified production capabilities through factory audits rather than reseller claims, prototyping services that reveal logo performance under real-world conditions, and material certifications aligning with your brand’s sustainability narrative. Start with a 200-500 unit pilot project using IML or hybrid techniques, measuring not just distribution completion but user retention rates and organic social sharing compared to previous promotional campaigns. As augmented reality integration and smart material technologies emerge, early partnerships with innovation-focused suppliers position your brand at the forefront of tactile-digital branding convergence. The manufacturers you choose today determine whether your logo becomes forgettable clutter or a trusted companion in consumers’ most frequent daily ritual—make that decision count.