From Design to Assembly: PCBMASTER’s Complete PCB Manufacturing and Prototype Services

In the rapidly evolving electronics industry, innovation and precision are key to success. Whether you’re developing cutting-edge consumer gadgets, industrial equipment, or medical devices, having a reliable partner for PCB design, PCB assembly, and manufacturing can make all the difference. That’s where PCBMASTER comes in—a trusted name offering complete printed circuit board (PCB) solutions from concept to production.

With years of experience, advanced facilities, and a dedication to quality, PCBMASTER has positioned itself as a one-stop solution for all PCB needs. From the early stages of PCB design to final PCB assembly, they provide end-to-end services that ensure accuracy, efficiency, and high performance.

A One-Stop Destination for PCB Design, Manufacturing, and Assembly

What makes PCBMASTER unique is its fully integrated service model. Many companies outsource different parts of their PCB process—one vendor for design, another for manufacturing, and yet another for assembly. This fragmented approach often results in communication gaps, quality issues, and delays. PCBMASTER eliminates these problems by offering a seamless workflow under one roof.

Their services include:

- PCB Design and Layout

- Prototyping and Quick-Turn PCB Production

- Full-Scale PCB Manufacturing

- SMT and THT PCB Assembly

- Quality Testing and Inspection

By managing every stage of production internally, PCBMASTER ensures complete control over quality, timing, and cost—something that’s vital for engineers, startups, and manufacturers alike.

Excellence in PCB Design

Every great electronic product begins with a well-thought-out design. PCBMASTER’s expert engineers understand the importance of layout optimization, component placement, and electrical performance. Their PCB design team uses advanced design software and follows Design for Manufacturability (DFM) guidelines to ensure each board can be produced efficiently and performs reliably.

From single-layer to complex multilayer designs, their engineers work closely with clients to create schematics that meet specific electrical and mechanical requirements. They specialize in high-speed, high-power, and high-frequency designs, handling challenges such as impedance control, signal integrity, and thermal management.

By offering full PCB design services, PCBMASTER helps clients reduce errors before manufacturing begins—saving both time and cost during production.

Advanced PCB Manufacturing Capabilities

After design validation, PCBMASTER’s manufacturing division takes over with precision and professionalism. Their state-of-the-art production facilities span 80,000 m², equipped with automated lines and inspection systems that ensure consistency and accuracy across every board.

Their PCB manufacturing capabilities include:

- 1–64 layer PCBs for standard and complex applications

- Advanced HDI (High-Density Interconnect) boards

- Metal-based and ceramic PCBs for thermal performance

- Rigid, flexible, and rigid-flex board production

- Impedance-controlled circuits for RF and communication devices

- Ultra-thin and heavy-copper boards for compact or high-power designs

Using advanced laser direct imaging (LDI), automated drilling, and AOI inspection, PCBMASTER maintains exceptional quality throughout production. Every board is made to meet strict international standards, including ISO 9001, IATF 16949, and UL certifications.

Rapid PCB Prototyping for Faster Innovation

Speed is essential in modern product development. PCBMASTER’s rapid prototyping service enables engineers to quickly test and refine their designs. With online instant quoting and small-batch production options, clients can receive PCB prototypes in record time without compromising on quality.

The company’s quick-turn service is ideal for startups and R&D departments that need functional boards fast for testing and proof-of-concept stages. This streamlined prototyping process ensures that any potential design issues are identified and resolved before full-scale production begins.

By combining fast lead times with top-tier materials, PCBMASTER allows businesses to move from concept to market with greater agility and confidence.

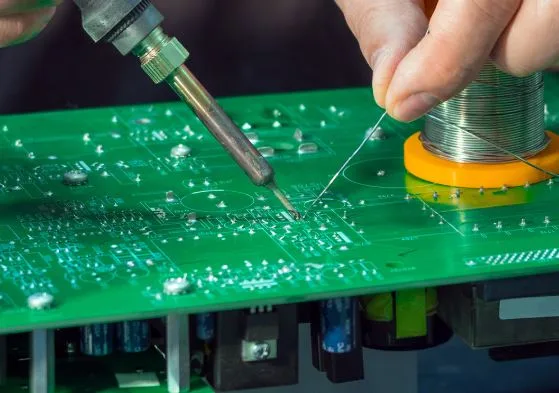

Precision PCB Assembly Services

Once boards are manufactured, the next critical step is PCB assembly—the process of mounting and soldering components onto the board. PCBMASTER’s advanced assembly lines are designed to handle the most intricate requirements, whether it’s surface-mount (SMT), through-hole (THT), or mixed assembly.

Their PCB assembly capabilities include:

- Automated SMT placement for components as small as 01005

- Fine-pitch BGA, QFN, and CSP assembly

- Lead-free and RoHS-compliant soldering processes

- Selective and wave soldering for through-hole components

- Automated optical inspection (AOI) and X-ray inspection for defect detection

PCBMASTER’s skilled technicians ensure that every component is placed with perfect alignment and soldered with precision. Their facilities are equipped with reflow ovens, solder paste printers, and inline inspection systems that guarantee consistent quality and performance.

This combination of automation and expertise allows PCBMASTER to deliver boards ready for immediate integration into final products.

End-to-End Testing and Quality Assurance

Quality is at the heart of PCBMASTER’s operations. Before any product leaves the facility, it undergoes rigorous testing to ensure it meets customer specifications and industry standards. Their inspection process includes:

- Electrical testing for open and short circuits

- AOI and X-ray inspection

- Functional testing for assembled PCBs

- Reliability and environmental testing when required

These strict quality control measures ensure that each PCB is free of defects and performs flawlessly in its intended application.

Benefits of Working with PCBMASTER

By offering complete PCB solutions under one roof, PCBMASTER provides numerous advantages over traditional fragmented approaches:

- Faster Turnaround Times – With integrated design, manufacturing, and assembly, projects move from idea to production in less time.

- Superior Quality Control – End-to-end oversight minimizes defects and ensures consistent standards.

- Cost Efficiency – Reduced logistics and communication costs lead to better overall project economics.

- Expert Technical Support – PCBMASTER’s engineers work closely with clients throughout the process to optimize designs and improve manufacturability.

- Scalable Production – From a handful of PCB prototypes to mass production, the company can scale seamlessly to meet customer demands.

These benefits make PCBMASTER an ideal partner for companies seeking a reliable, experienced, and innovative PCB supplier.

Serving a Wide Range of Industries

PCBMASTER’s expertise spans across multiple sectors, including:

- Consumer electronics

- Automotive systems

- Industrial automation

- Telecommunications

- Medical and aerospace technologies

Each of these industries demands exceptional precision and reliability—two qualities PCBMASTER consistently delivers through its comprehensive PCB design, PCB assembly, and manufacturing services.

Conclusion

In today’s competitive electronics market, success depends on having a dependable partner who can manage every aspect of PCB production. PCBMASTER offers a truly integrated approach, guiding clients from PCB design and prototyping to PCB assembly and final production. Their dedication to quality, precision, and innovation ensures that every board meets the highest industry standards.

Whether you’re developing a new product, testing a prototype, or preparing for mass production, PCBMASTER provides the expertise, technology, and reliability to bring your ideas to life.

Visit www.pcbmaster.com to explore their full range of PCB solutions and experience world-class manufacturing tailored to your needs.