Differences Between Hand-Woven and Machine-Woven Carpets

What Defines Hand-Woven and Machine-Woven Carpets?

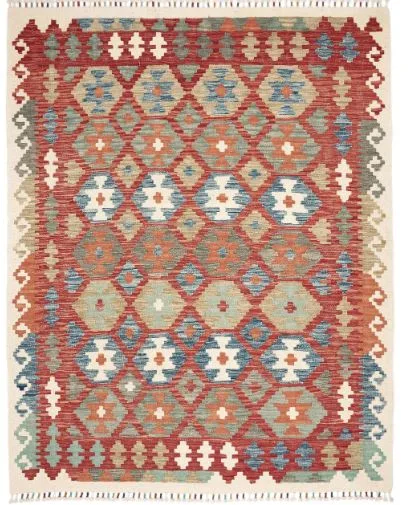

Hand-woven carpets are created by artisans using manual looms. This method requires time, skill, and close attention to detail. Each knot is tied individually, making every carpet slightly different. Machine-woven carpets, on the other hand, are produced by automated looms that follow programmed designs. The output is faster and highly consistent in appearance.

The two production methods lead to different physical results. Hand-woven carpets often have slight imperfections that show they are handmade. Machine-woven carpets look uniform because machines control every step. The back side of hand-woven carpets usually mirrors the front design, while machine-made ones have a separate backing layer made from synthetic materials.

Materials Used in Carpet Production

Hand-woven carpets typically use natural fibers like wool, silk, and cotton. These materials are chosen for their durability, texture, and ability to absorb natural dyes. The colors in these carpets tend to vary slightly, adding depth to the overall look. These natural fibers also help with insulation and sound absorption in indoor spaces.

Machine-woven carpets mostly contain synthetic fibers such as polypropylene, polyester, or nylon. These materials are cheaper to produce and offer stain resistance. However, synthetic fibers wear out faster and can feel less comfortable underfoot. Color in machine-woven carpets appears uniform, and patterns remain consistent across multiple pieces.

The fiber type directly affects the carpet’s performance. Wool is elastic and resilient. Silk gives a smooth texture and a natural sheen. Synthetic fibers prioritize functionality and low cost but compromise longevity and comfort.

Durability and Maintenance Differences

Hand-woven carpets are long-lasting when properly cared for. They are often passed down across generations. The tightness of the knots and the quality of the materials directly influence how well these carpets hold up over time. Many antique carpets still maintain their structural integrity and color richness.

Machine-woven carpets usually last between 5 and 15 years, depending on usage and quality. They are more prone to wear in high-traffic areas. Their construction, often with lower knot density and synthetic threads, limits their durability. As they age, patterns may fade and the backing may weaken.

Caring for both types involves regular cleaning. Hand-woven carpets need more delicate methods, such as low-suction vacuuming or professional dry cleaning. Machine-woven carpets can be cleaned with standard equipment and chemical products. Repairs are easier with hand-woven carpets because damaged areas can be rewoven, unlike machine-made carpets, which often require replacement.

Design Variety and Visual Appearance

Design is a key factor that separates these two types. Hand-woven carpets allow for complex, asymmetrical, and culturally specific designs. These designs often reflect regional traditions from areas like Persia, Turkey, or the Caucasus. Every hand-woven piece can carry slight variations, even within the same pattern.

Machine-woven carpets follow pre-set digital patterns. The level of detail is limited by machine settings, and every copy is identical. While this allows for faster production, it also reduces uniqueness. The use of synthetic dyes ensures consistent coloration across each unit.

Color depth in hand-woven carpets often appears more dynamic. This is due to natural dye absorption, which interacts differently with each fiber. Machine-made pieces look flatter, with clean, even colors. The difference becomes more noticeable in larger designs with gradient tones.

Pricing and Market Segmentation

Hand-woven carpets usually have a higher price point. This reflects the time, skill, and quality of materials involved. They are often viewed as long-term investments or even collectible pieces. Their value can increase over time, especially if they are rare or from a recognized region. http://ogretmenlerhali.com/collections/el-dokuma-halilar

Machine-woven carpets are produced for affordability and mass availability. They are suitable for consumers looking for quick and cost-effective solutions. These carpets are widely available in retail stores and online platforms. Their resale value is generally low.

The market treats these products differently:

- Hand-woven carpets are sold in galleries, auctions, or through dealers.

- Machine-woven carpets are sold through mass-market retailers and large e-commerce sites.

Environmental Impact and Sustainability

Hand-woven carpets made from wool, cotton, or silk have a lower environmental footprint. These materials are biodegradable and require less energy during production. Natural dyeing processes are also less harmful to ecosystems when compared to synthetic dyes.

Machine-woven carpets use synthetic materials derived from petroleum. Their production consumes more energy and creates more industrial waste. These carpets are harder to recycle and often end up in landfills after disposal.

The impact of each carpet depends on its full life cycle. Natural fiber carpets can be repaired and reused. Synthetic ones are harder to restore, and their environmental cost is higher from production to disposal.

Identifying and Verifying Carpet Types

There are clear physical clues to tell these two types apart. Hand-woven carpets show slight irregularities in the weave and have knots visible on the back. Their fringes are often part of the structure, not sewn on separately. Machine-woven carpets have clean, repeated patterns and a backing layer that hides construction details.

Many hand-woven carpets come with certificates of authenticity. These are issued by reputable institutions and confirm the origin and materials used. Labels on machine-woven carpets usually list fiber content and country of manufacture, but do not confirm artisan involvement.

You can also look for digital tags or QR codes on modern pieces. These may link to information about the product’s history and materials, but traditional authentication still relies on expert inspection.

Functional Use and Ideal Applications

Hand-woven carpets work best in areas where appearance and long-term value matter. These include living rooms, formal spaces, and heritage buildings. Their texture and design can enhance the overall interior quality. They are often used as statement pieces, not just floor coverings.

Machine-woven carpets are preferred in busy, high-traffic spaces. These include offices, hotel rooms, and public venues. They are easy to replace and clean, making them suitable for practical use. Their functionality outweighs the need for uniqueness in these contexts.

Some technical features also differ:

- Machine-woven carpets often include stain-resistant treatments.

- Hand-woven carpets can be treated for fire safety, but this requires additional processing.

Summary of Key Differences

Hand-woven carpets are made manually with natural materials and offer design depth and long-term durability. Machine-woven carpets are mass-produced, more affordable, and better suited for short-term or practical use. Choosing between them depends on budget, usage, and aesthetic preferences.

The differences involve:

- Production method

- Material composition

- Design possibilities

- Durability and care

- Environmental impact

- Market positioning

Each type has a clear function and target user. Understanding these distinctions helps in making informed decisions when selecting carpets for different environments.