Custom Cut to Size Foam Solutions – Bringing Comfort & Precision Together

Introduction

From upgrading an old sofa to designing creative interiors or assembling safe packaging for valuable medals, the importance of perfectly shaped foam cannot be overstated. Today’s homeowners, upholsterers, and manufacturers increasingly rely on Cut to size foam services to achieve the exact comfort level, shape, and durability their projects demand.

This article explores how custom foam is made, where it can be used, and why these tailored solutions deliver better comfort and longer-lasting value than pre-cut alternatives.

1. The Growing Need for Tailored Foam Solutions

Modern furniture design, home renovations, and commercial upholstery projects all share one requirement: precision. Standard foam blocks are often too large, too thin, or too soft, forcing people to compromise on comfort or quality. That’s where Foam cut to size becomes the ideal solution.

Whether you’re refreshing your armchair cushions, building seating for a campervan, or creating protective compartments for delicate medals, tailor-made foam ensures:

- A perfect fit

- Consistent comfort

- Longer durability

- Better safety for stored or transported items

Because each piece is produced exactly to your dimensions, you don’t waste material, time, or money. You simply get foam that meets your needs—down to the millimetre.

2. A Wide Range of Foam Shapes for Every Project

One of the major advantages of using a professional foam converter is the ability to choose from a variety of shapes. Thanks to advanced cutting techniques, foam can be crafted into simple or complex forms with ease.

Rectangle Cushions

The most popular choice, ideal for:

- Seat bases

- Back cushions

- Benches

- Packaging for ornaments, collectibles, or medals

T-Shaped Foam Pieces

These cushions fit perfectly into sofas and armchairs that use T-style seating pads, removing gaps and restoring comfort.

Wedge Cushions

Designed to support posture, these wedges are widely used in:

- Orthopaedic seating

- Elderly care products

- Automotive seats

- Office chairs

L-Shaped Designs

These are often used for:

- Corner sofas

- Modular furniture

- Bay window seating

Tapered Cushions

For seating areas where a slight slope is required, tapered foam offers ergonomic support and a smoother sitting experience. Available in both equal taper and one-side taper designs.

Fully Custom Shapes

If your project involves a curved design, unusual angle, or specific depth, custom Cut to size foam services ensure it fits exactly as needed—ideal for boats, caravans, unique furniture builds, or display boxes for awards and medals.

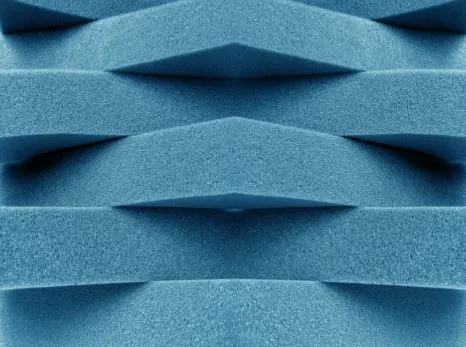

3. The Craftsmanship Behind High-Quality Foam

Behind every well-made cushion or supportive foam pad lies a carefully organised manufacturing process. Professional foam converters rely on technology, technical skill, and years of experience to deliver consistent results.

Precision Cutting Using CNC and Band Knives

These tools allow for:

- Accurate measurements

- Smooth, clean edges

- Perfect replication for bulk orders

No matter the shape, the machinery is calibrated to produce exact dimensions, ensuring every foam piece fits like it was made for your project—because it was.

Density Control Through Foam Pressing

Pressing machines help compress and stabilise foam, enhancing:

- Longevity

- Resilience

- Comfort retention

This ensures the foam stays supportive even after extended use.

Layer Bonding for Specialised Applications

Sometimes, a cushion needs more than one type of foam. At adhesive stations, multiple layers can be combined to achieve:

- Dual-density seating

- Extra firmness where needed

- Soft surface comfort with a strong inner core

This craftsmanship is what separates premium Foam cut to size from store-bought alternatives.

4. Where Cut to Size Foam Makes a Difference

Custom foam is used across a wide variety of sectors. Its flexibility, durability, and ability to be moulded into any shape make it one of the most adaptable materials available.

Furniture & Upholstery

From sofas to armchairs and bench seats, made-to-measure foam is the fastest way to restore comfort to old furniture.

Automotive & Campervan Projects

Car seats, motorcycle seat pads, and campervan bedding all benefit from high-density, tailormade foam that offers support during long journeys.

Bedding & Mattresses

Foam cut to exact sizes helps create:

- Mattress toppers

- Custom-sized beds

- Therapeutic sleeping pads

Medical & Orthopaedic Use

Foam is essential in creating items such as:

- Wheelchair cushions

- Therapy blocks

- Orthopaedic supports

Packaging & Protective Applications

Foam cut to size is widely used for:

- Fragile items

- Instrument cases

- Awards, coins, and medals

- Delicate electronics

With custom contours, valuable items stay secure during storage or transportation.

Retail & Manufacturing

Many large and small businesses rely on foam converters to supply consistent, high-quality foam components for their products.

5. Simple Steps to Ordering Bespoke Foam

The ordering process for Cut to size foam is straightforward, whether you’re a business owner or a homeowner updating your space.

Step 1: Select Your Shape

Choose from rectangles, wedges, L-shapes, T-shapes, or request a custom template.

Step 2: Add Your Measurements

Accurate length, width, and depth ensure a perfect fit.

Step 3: Pick the Foam Grade

From soft and bouncy to firm and supportive, different grades suit different purposes.

Step 4: Choose Optional Add-Ons

Extras like:

- Dacron wrapping

- Stockinette covering

make cushions easier to slide into covers and give them a softer outer feel.

Step 5: Complete Checkout

Once everything is selected, your order goes into production.

Step 6: Quick UK-Wide Delivery

Your foam is cut, packed, and delivered directly to your door.

This easy process allows anyone—DIY enthusiasts, professionals, or manufacturers—to design the perfect foam in minutes.

6. Key Advantages of Using Cut to Size Foam

Better Comfort

Tailor-made foam provides the exact level of firmness you need, making seating more supportive and comfortable.

Long-Term Durability

High-quality foam maintains its shape and strength for years, even in heavy-use environments.

Precise Fit

No reshaping or trimming needed. Foam cut to your exact measurements fits perfectly every time.

Versatility

From home furniture to packaging delicate medals, the uses for custom foam are endless.

Safety Assured

UK-made foam complies with national fire-safety standards, making it suitable for homes and businesses.

Cost-Effective Upgrades

Instead of buying new furniture, replacing the foam inside cushions can restore comfort at a fraction of the cost.

7. Conclusion

Custom Cut to size foam offers comfort, precision, and quality for everything from home seating and commercial upholstery to packaging, medical supports, and storage for delicate medals or collectibles. With advanced cutting machinery, skilled craftsmanship, and UK-wide delivery, Foam cut to size services make it easier than ever to get exactly what your project needs.

Whether you’re upgrading a sofa, fitting out a campervan, creating protective storage, or designing specialised equipment, tailor-made foam provides reliability, longevity, and unmatched comfort—crafted exactly the way you want it.