Choosing Air Rock Drill Bits: A Guide to PDC and Tricone Use

Anyone who has drilled hard rock with compressed air knows the bit—not the rig—is usually the deciding factor in whether a shift runs smoothly or becomes a fight with the ground. When the wrong bit meets the wrong formation, performance issues show up fast: penetration slows, cuttings stop clearing, and gauge wear accelerates until the bit has to be pulled long before its expected life. Bit selection is not a minor detail in air drilling; it directly affects cost per meter, productivity, and borehole quality.

Understanding how air bits perform—and how they compare to PDC and tricone options—is essential for choosing the right tool for any formation.

Air Drilling Has Its Own Rules

Air drilling is often misunderstood as “fluid drilling without the fluid,” but the two environments behave very differently. Instead of relying on drilling mud to cool the bit and suspend cuttings, air drilling depends entirely on high-velocity airflow. This increases heat concentration, makes flushing more directional, and exposes the bit to more direct contact with the formation.

These conditions make air drilling extremely effective in dry, hard rock. But they also make it unforgiving when the bit’s geometry or material doesn’t match the geology. If air flow, rock behavior, and bit design aren’t aligned, the drop in performance is immediate.

What Air Rock Drill Bits Are Designed to Do

Air rock drill bits are purpose-built to survive rapid impact cycles, elevated temperatures, and aggressive flushing. They rely on durable carbide buttons, optimized face shapes, and air channels that keep cuttings moving. Because air drilling has less tolerance for inefficiency than fluid systems, choosing the correct bit determines whether the hammer’s energy translates into actual progress.

For operators reviewing different bit configurations, the range of air rock drill bits provides a good example of how face design, button geometry, and air passages influence bit behavior in various formations.

Formation Comes First—Always

The most reliable way to choose a suitable bit is to evaluate the geology first.

- Hard, abrasive rock → hemispherical buttons + flat faces for maximum durability

- Medium-hard stable formations → concave faces for self-centering and smoother drilling

- Fractured rock → designs that reduce deviation and maintain gauge

- Soft homogeneous rock → ballistic buttons for higher ROP, if abrasiveness allows

Experienced drillers know the formation dictates the cutting mechanism. The first question isn’t “Which bit do we have?” but “How does this rock tend to break?”

Design Details That Influence Performance

Two bits with similar diameters can behave very differently depending on their design. Small geometrical features control how effectively impact energy reaches the rock and how efficiently cuttings are removed.

- Button shape affects wear rate and penetration speed.

- Bit face design controls flushing efficiency and stability.

- Carbide grade determines resistance to heat and micro-fractures.

- Flushing-hole arrangement influences whether cuttings escape cleanly or recirculate.

These details determine whether the bit drills steadily—or wastes energy through vibration and heat.

Why PDC and Tricone Bits Enter the Discussion

Once drillers understand how formation and design dictate bit performance, it becomes clear why comparisons with PDC and tricone bits are common. When geology shifts or production targets change, different cutting mechanisms may offer better stability or efficiency. That’s why job sites frequently refer to guides like Sinodrills PDC vs Tricone—each bit type responds differently to variations in hardness, abrasion, and fracture patterns. Knowing these differences helps crews determine whether a performance issue comes from the formation, the air system, or simply the wrong bit.

Where PDC Bits Excel—and Where They Don’t

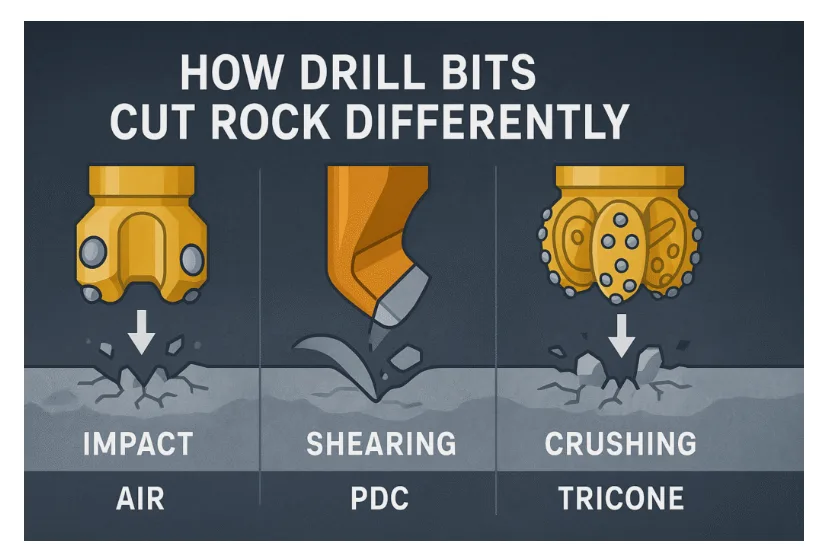

PDC bits shear rock instead of crushing it. This gives them exceptional ROP in soft to medium-hard formations, especially where geology is predictable. Their cutters operate smoothly without moving parts, which reduces failure points.

But PDC bits lose efficiency in fractured, abrasive, or highly variable formations. Vibrations can chip cutters, and inconsistent rock layers interrupt the shearing action. When conditions are stable, PDC can outperform most alternatives. When geology changes rapidly, it may become unreliable.

Why Tricone Bits Still Perform Well in Variable Geology

Tricone bits crush rock using rolling cutters, allowing each cone to adapt to changing hardness. This makes them highly effective in interbedded, abrasive, or unpredictable formations where PDC or air bits may struggle. While tricones generally offer lower peak ROP than PDC, they maintain steady progress and reduce risk of bit damage, especially in complex geology.

Their greatest strength is consistency: when formations stop behaving predictably, tricones keep drilling.

A Practical Decision Process

Choosing the right bit is easier when approached systematically:

- Identify the formation — abrasive, fractured, soft, or hard

- Understand the drilling environment — air flow, water intrusion, pressure limits

- Match the cutting action

- Impact → Air bits

- Shearing → PDC

- Crushing → Tricone

- Evaluate cost per meter, not bit price

A more expensive bit often reduces total drilling cost if it matches the geology better.

Common Mistakes to Avoid

Some errors repeatedly cause downtime on job sites:

- Running PDC bits in fractured zones

- Using tricone bits where soft rock enables faster shearing

- Selecting the wrong button geometry for abrasiveness

- Ignoring air pressure limitations

- Choosing bits based solely on price

The geology always announces what it wants—ignoring those signals is the real cause of wasted money.

Conclusion

Air drilling is one of the most efficient ways to cut through hard, dry rock, but only when the bit’s geometry and cutting mechanism match the formation. Understanding how air bits work—and how their performance compares with PDC and tricone designs—helps crews drill more efficiently, extend bit life, and control project costs. The right bit choice doesn’t just improve penetration—it improves the economics of the entire operation.