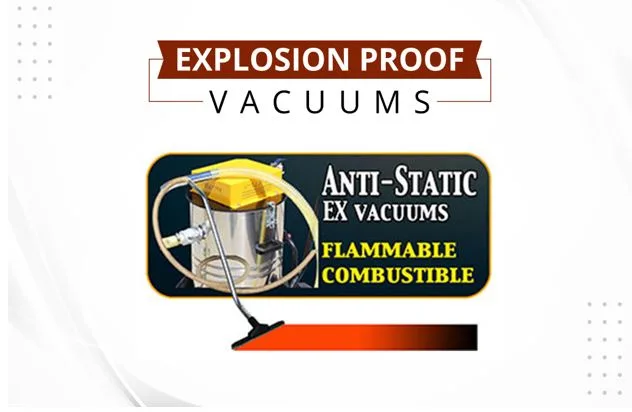

Explosion-Proof Vacuums: Understanding Safety Requirements and Certification

Wherever burning gases, vapors, or dust that support burning are present, safety has to be of primary importance. A custom designed explosion proof vacuum is purpose-made to function in an upright manner within these hazardous environments without the risk of ignition. Possible ignition at the vacuum’s unsafe installation or operation is thereby eliminated. Sparking, static discharge, and excessive heat that could potentially lead to ignition of the volatile material.

Explosion-proof vacuums are essential in industries like chemical manufacturing, metalworking, food processing, pharmaceuticals, or mining. The list is basically ongoing, whose issues with fine dust or vapors can create explosive atmospheres.

Key Safety Requirements

1. Certified Equipment

Ensure to utilize full-system explosion proof certified vacuums, not just component level, as the safety standards per the hazardous area are being met against the risky environment in which the vacuum is used. The main testing bodies recognized are UL, CSA, ATEX, and IECEx.

What does this certification say? It simply indicates/declares the fact that the vacuum has been designed with fixed clasps, such as the motors, wiring, filter, and other included accessories, that would prevent sparks or any ignition/ignition sources from being part of inherent personal injury under a certain judgment or normal and abnormal circumstances.

2. Hazard Classification

Each hazardous location is categorized depending on the presence and consignment of explosive/inflammable materials:

Class I: Flammable gases or vapors

Class II: Combustible dusts

Division 1: Hazard present under normal operation

Division 2: Hazard present only under abnormal operation

To comply with global standards, ATEX (European) and IECEx (International) systems are similarly classified into Zones 0/1/2 for gases and Zones 20/21/22 for dust.

3. Safe Filtration System

The filtration system shall do the job to contain combustible dust without leaks or re-entrainment. Mostly, explosion proof HEPA vacuums utilize multistage filter options that come with HEPA filtration of 99.95% efficiency to collect particles down to 0.3 microns. In addition, a cyclone separator or pre-filtration might be required when dealing with very fine or reactive dust to prevent overloading of a particular dust through the HEPA filter.

4. A Tough Build

Explosion-proof vacuums demand specific design and construction materials. These vacuums are well-constructed and manufactured from a range of heavy-duty conductive materials like stainless steel or aluminum; they are designed with minimum moving parts and concealed or air-driven mechanisms to avoid electrical hazards in the vacuums. Air-operated explosion proof pneumatic vacuum cleaners are most favored in extremely explosive zones where there is no electrical utilization, thereby reducing the risk of ignition.

Why Explosion-Proof Vacuums Are Essential

1. Handler Safety

The main function of explosion-proof vacuum cleaners is the safety of people. Even a microscopic speck of a spark may cause an explosion in any premises with powders (for example), solvents, chips, or chemicals. These vacuum cleaners are designed with toolbox parts that are in metallic construction, anti-static components, and objects whose strips are grounded.

2. Regulatory Compliance

What about running only one shift around the clock, six days a week, to allow for cleaning, vacuuming, or blasting because other explosion proof wet/dry vacuum systems cannot be used in the hazardous area, are not certified for explosive atmosphere compliance, or lack design features to effectively collect dust, pick up large granules, wet-pick and contain, and minimize clogging, let alone discharge the dry fine dust into larger bags and keep the shop or site clean? Within days, toxic dust could occur. in: not to mention an influx of all these wind odds and various workforce-crossing health and safety costs!

3. Insurance Compliance

Insurance providers have a keen eye on the safety measures taken by factories, especially in those sectors where combustible dust is present. In that case, the use of certified explosion-proof vacuums is an absolute must for getting the insurance coverage. By having the right equipment, the occurrence of accidents is less likely and therefore meeting insurance requirements, reducing premiums, and getting claims approved become a great deal easier. Besides, the investment in compliant systems speaks for itself, as it shows a strong commitment to safety and risk management.

4. Protection of Assets

In an industrial setting, expensive machinery, sensitive systems, and valuable stock are all part of the picture. The mere occurrence of a dust explosion or fire can, in a matter of seconds, lead to the annihilation of these assets. The risk is greatly reduced as explosion proof vacuums work to eliminate the lighting-up sources in the course of routine cleaning and material recovery activities. They capture hazardous dusts and volatile residues in a safe manner, thus preventing their accumulation, which could ignite later on. This proactive protection gives equipment an extended life and also contributes to the establishment of a safe production area.

Common Misconceptions

1. “Any and every pneumatic vacuum is explosion-proof.”

Not in every case. The use of air-operated vacuums leads to less likelihood of electrical ignition but still grounding and certification of the equipment for the hazardous area are required.

2. “HEPA filters by themselves make a vacuum explosion-proof.”

HEPA filters do contribute to the quality of the air but do not keep the fire from starting. The explosion-proof design has the components of static control, grounding, and a containment measure.

3. “Only the motor needs certification.” Wrong.

The entire vacuum assembly has to be tested and certified in order to rule out any part being a source of ignition.

Example Features of a Certified Explosion-Proof Vacuum

- Anti-static, conductive construction

- Fully grounded design

- Intrinsically safe motor or pneumatic drive

- Multi-stage HEPA filtration

- Spark-free components

- Compliance with ATEX or Class/Division codes

Benefits Beyond Safety

Explosion-proof vacuums are not only a safety measure but also a productivity booster. The heavy-duty construction of these machines makes possible:

- Filter-less operation time that is longer than usual

- Better control of dust, hence less contamination

- Maintenance expenses that are lower than usual because of the vacuum’s rugged design

- Air that is cleaner, thus contributing to healthier offices

- These vacuums with HEPA filtration have the ability to get rid of dangerous particles, and at the same time, there are no ignition risks through prevention.

Choosing the Right Manufacturer

While looking for an explosion-proof vacuum, choose an industrial vacuum manufacturer or supplier that offers you:

- Full certification papers

- On-site technical assistance and backup parts

- Specialized solutions for your industry’s risk factors

- Validated experience in ATEX or Class/Division compliance

Training and documentation should be given by the manufacturer as part of their service package.

Conclusion

In hazardous work environments, explosion-proof vacuums are not merely considered to be tools but rather, life-saving essentials. Selecting the proper unit requires thorough knowledge of certifications, filtration systems, and anti-static design.

It does not matter if you are operating with a HEPA filter pneumatic vacuum or a full-scale industrial vacuum system; the important thing is that your equipment is certified, grounded, and right for the classification of your environment.

When you invest in the right explosion-proof solution, you are not just complying with the law but also securing safety and getting peace of mind, all while maintaining efficient operations.