Axis CNC Machining: Unlocking Precision and Efficiency in Complex Part Production

Introduction

The big challenge for engineers and producers in these two high-stake manufacturing industries-aerospace and medical devices-is how to manage the growing demand for complicated geometries such as free-form surfaces, thin walls, and deep cavities so that performance can be maximized. Traditional manufacturing methods, however, are reaching significant bottlenecks, including long production cycles, lost precision due to multiple setups, high scrap rates, and hard-to-control costs. This greatly stifles product innovation and time-to-market. The root cause is that conventional 3-axis CNC machining is not flexible, accessible, and single-setup capable of accommodating increasingly modern, integrated, lightweight complex parts. With its unique capability of multi-axis synchronization and single setup, 5-axis CNC machining technology now stands out as the key to opening up superior production in terms of accuracy and efficiency. It is more than equipment upgrading; it marks a whole different philosophy in manufacturing, capable of optimizing the whole production workflow from zero.

This article tries to explain in what way the bottlenecks mentioned above have been tackled with 5-axis technology and how one chooses a true strategic partner, rather than just a machining service provider.What are the main bottlenecks of 3-axis machining in modern manufacturing?

Whereas it can handle simple parts sufficiently, traditional 3-axis CNC machining exposes important limitations when real demands are made in complex geometry machining. The nature of these bottlenecks needs to be understood first before understanding the advantage of 5-axis.

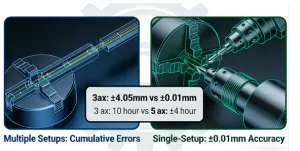

1. Cumulative Error from Multiple Setups

The biggest drawback of this process is the necessity of using multiple setups to be able to machine different sides of a workpiece. Each repositioning can provide an opportunity for error, thereby resulting in accumulative inaccuracies in hole positions, profile alignments, and overall geometric dimensioning and tolerancing. A feature machined in setup two might result in misalignment with features done in setup one, compromising the functional integrity and the fit of the part in an assembly.

2. Stair-Stepping and Surface Quality Issues on Contours

During machining of curved surfaces, this linear motion of a 3-axis system results in a “stair-stepping” effect. In order to minimize this effect, ball-end tools with minimum step-over distances are used, but the tooltip has near-zero cutting speed and is therefore rubbing rather than cutting. This results in poor surface finish, accelerated tool wear, and exponential increases in machining time, affecting aerodynamic performance or aesthetic quality of the machined part.

3. Tool Accessibility and Challenges with Deep Cavities

The fixed tool orientation has serious limitations in reaching deep cavities, undercuts, and other complex internal features. This, consequently, makes many tool holders collide with the workpiece, a factor that mostly compels designers to sacrifice such optimal single designs and split them into a lot of simpler parts. These, in return, increase part count, assembly steps, and potential failure points, undermining the need for an integrated reliable design. And again, reaching the deep features also requires long tools, which are subject to vibration, hence reducing accuracy and surface finish.

How Does 5-Axis CNC Technology Achieve Single-Setup Machining and Enhance Precision?

- axis CNC machining is a technological leap that has been achieved by adding two more rotational axes to the three linear axes, such as A/C or B/C. This allows for dynamic tool orientation control, meaning the cutting tool can approach the workpiece from virtually any optimal angle.

Figure 2: Comparison of 3-axis (multiple setups) and 5-axis (single-setup) machining, showing how 5-axis technology reduces errors and cycle times by over 50% for complex parts.

- The Mechanics of Multi-Axis Motion Kinematics: On a standard 5-axis machine, the rotational axes are configured on a table-table, head-head, or table-head arrangement. This offers the capability to continuously change the tool orientation about the workpiece throughout the cycle. As an example, the workpiece can be tilted and rotated simultaneously, allowing the tool always to maintain the most efficient cutting angle during the cycle, which is the principle of true single-setup machining.

- Eradication of Error – Releasing Geometric Freedom: 5-axis technology eliminates repositioning errors by completing an entire part in one setup; all features are machined relative to a single datum. This is critical for meeting stringent standards such as ASME Y14.5. Moreover, it provides unparalleled geometric freedom. Tools can make much better use of their side-cutting edges-flank milling-dramatically increasing material removal rates and surface finish on complex contours. This capability is essential when working with organic-shaped components, including impellers, turbine blades, and medical implants.

- Tangible Efficiency Gains: A Case Example: The practical advantages are significant. Think of a turbine blade that requires three settings and takes up to 12 hours on a 3-axis machine. This same part is completed in less than 6 hours on a single setup through the power of 5-axis CNC machining. In fact, it reduces the machining time by more than 50%, minimizes manual handling, saves fixture costs, and avoids mistakes, thereby reducing overall cost by a difference of more than 30%. To manufacturing customers looking for a reliable 5-axis CNC machining service, this level of efficiency is nothing short of transformative.

More than just machinery-What skills make a world-class 5-axis machining partner?

Owning a 5-axis machine is only the beginning. The value is in the integrated capabilities of the partner-a true manufacturing solution.

1. Advanced Cam Programming And Toolpath Optimization

5-axis machining enjoys its fullest potential through advanced CAM software. Experts make use of software, such as Siemens NX, in order to create smooth, collision-free toolpaths that now integrate XYZ and rotational coordinates. Key strategies will involve tool axis vector control to maintain ideal cutting angles and sophisticated interpolation algorithms to avoid abrupt changes in direction or pitch, assuring constant cutting forces and superior surface finishes on tough materials such as titanium.

2. Expertise in Material Science and Cutting Dynamics

A world-class partner has expert knowledge of material-specific machining strategies. They would maintain databases for hard-to-machine alloys, such as Inconel, and engineering plastics, optimizing the parameters of the cut, tool selection, and coolant application to avoid work hardening, heat deformation, or delamination.

3. A Robust Quality Management System

For regulated industries, a systemic approach to quality is non-negotiable. This means beyond final inspection, the use of on-machine probes for in-process verification, and full first-article inspection with CMMs. A partner whose core competencies are underpinned by certifications such as AS9100D (aerospace) and ISO 13485 (medical devices) demonstrates a commitment to rigorous process controls and full traceability throughout the entire production process.

How does scientific DFM analysis achieve cost-effectiveness without sacrificing quality?

Design for Manufacturability is a strategic collaborative process wherein 5-axis machining cost-effectiveness is maximized by optimizing part design in advance of production.

- Feature Consolidation and Setup Reduction: A scientific DFM analysis proactively identifies opportunities to consolidate multiple features into a single, more manufacturable design. By designing parts that can be machined in one or two setups, DFM eliminates the need for numerous custom fixtures, significantly reducing both time and cost.

- Geometric Optimization for Efficient Machining: DFM experts advise on design elements such as the specification of internal corner radii that would allow the use of standard tooling and not expensive, custom-made tools. They guide intelligent wall thickness transitions and selection of datum for stable machining and accurate measurement to reduce material waste and machining time.

- Application of Strategic Tolerance: Not every surface needs a tight tolerance. It is an important part of DFM, identifying the critical functional surfaces, and those that aren’t as critical. By applying only the necessary tight tolerances, manufacturers can save substantial money on machining and inspection without sacrificing the performance of the part in its intended application. Partnering with a supplier offering a fast online CNC machining quote that includes DFM analysis is the first step to these savings.

Can 5-Axis Machining Meet the Stringent Demands Imposed by High-Performance Alloys in Aerospace and Medical?

Indeed, 5-axis machining is not only compatible with high-performance materials, but often these are the preferred methods for producing critical components from them.

1. Tackling Aerospace Challenges: The Case of Turbine Blades

Aerospace components in high-temperature alloys such as Inconel pose issues like extreme hardness and tendency to work-harden. 5-axis machining overcomes the above issues with specifically designed tool geometries, high-pressure coolant systems that manage heat, and strategic toolpaths to maintain consistent chip loads. Single-setup capability is critical to maintaining turbine blade aero-profile and structural integrity throughout its lifecycle.

2.Precision for Life – Medical Implants made from Titanium and PEEK

The components, such as orthopedic implants, have specific high demands on biocompatibility and, at the same time, very complex geometries. 5-axis technology enables the precise machining of titanium and advanced polymers, such as PEEK, into patient-specific implants with the required porous surfaces that provide for bone integration. Process stability ensures repeatability and the high surface finishes that minimize infection risk.

How is Precision Maintained Throughout the Entire Manufacturing Lifecycle?

A holistic quality control system integrated directly into the manufacturing workflow is needed to sustain precision from the first part to the last in a production batch.

1. Preventive Control: First-article validation

It starts with the full inspection of the first article. The first part is fully measured by CMM or 3D scanner; data is compared directly against the original CAD model to validate the machining program and ensure all dimensions are within specification.

2. In-Process Monitoring and Real-Time Intervention

In-process monitoring maintains precision during production. On-machine probing checks critical dimensions between operations, automatically compensating for tool wear or thermal drift. This closed-loop feedback ensures that the process stays in control without removing the part and protects manufacturing efficiency and accuracy.

3. Final verification – Data traceability

Full inspection is always carried out after machining on final parts. In the case of complicated surfaces, there exists a full deviation map thanks to noncontact scanning. All inspection data will be documented and archived properly to offer full traceability. This approach to quality, using data as the driver, follows ISO 9001 principles of quality management to build a culture of continuous improvement along with consistent compliance.

Conclusion

5-axis CNC machining effectively unlocks long-standing bottlenecks in the making of complex parts through its revolutionary single-setup capability, enabling unparalleled gains in precision and efficiency. To fully realize this value, however, requires close collaboration with a knowledgeable partner who can bring deep process knowledge, scientific DFM analysis capabilities, and a rigorous quality system. It is this strategic partnership that turns advanced technology into competitive advantage.

FAQs

Q1: Does 5-axis CNC machining apply to prototyping, or is it only for mass production?

A: It is exceptionally well-suited for prototyping. The foremost advantage of the process is that it can manufacture complex geometries in a single setup, thereby saving time and costs required for designing and manufacturing a number of fixtures for 3-axis machines. This gives speed to the iteration cycles and allows the testing of parts representative of the final design.

Q2: What is the basic difference between a table-table and a head-head 5-axis machine?

A: The primary difference is how the rotational axes are achieved. A table-table has two rotary axes in the table, ideal for small to medium-sized heavier parts. A head-head has rotational axes in the spindle head, which is best for very large parts. A hybrid “table-head” configuration offers a balance; the choice depending on part size, weight, and required accuracy.

Q3: How would the quotation process normally go for this 5-axis machined part?

A: The process starts with the submission of a 3D model. Good suppliers do a DFM analysis, which is often included in the quote to highlight problems in production and suggest optimizations. Finally, the quote needs to provide transparency in its cost breakdown based on material, machining time, and special processes.

Q4: What materials are treated efficiently with 5-axis CNC machining?

A: 5-axis machining is highly versatile and capable of processing a great variety of materials, from metals such as aluminum, titanium, and stainless steel to engineering plastics like PEEK and PEI. The thing is, the provider needs to develop appropriate cutting tools, speeds, feeds, and cooling for the specific material being treated.

Q5: How does an effective quality control system integrate with 5-axis machining?

A: Advanced quality control-including in-process verification and tool wear compensation-is ensured through on-machine probing. First-article inspection by CMMs serves to validate the program. Comprehensive data is provided through non-contact scanning for complex surfaces. SPC maintains production stability in check to ensure that quality is maintained through each batch.

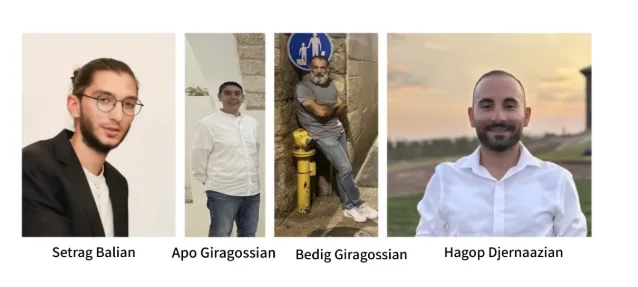

H3: About the Author

The author is a precision manufacturing professional at LS Manufacturing. It is an innovative manufacturing company dedicated to solving challenging part requirements by providing quality solutions for engineers and researchers in the aerospace, medical, and automotive industries. We guarantee outstanding solutions from prototype through production with a team based on state-of-the-art technologies adhering to the harshest quality standards. For more information, contact us today for your free, no-obligation project review and DFM analysis that will make your concept a cost-effective reality.