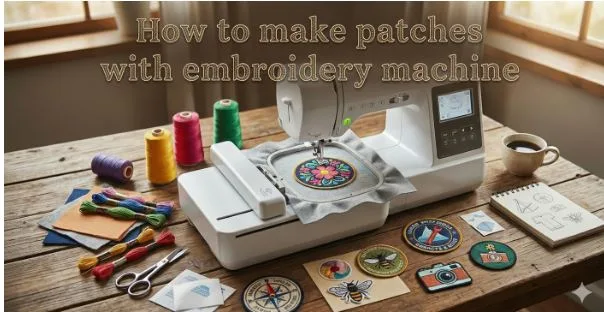

How to make patches with embroidery machine

Introduction to Embroidery Patches and Their Uses

Embroidery patches have been around for ages due to their effectiveness and overall design. Custom Patches are used for Branding, Uniforms and Growing the brand. Embroidery patches are a type of embroidered designs that can be attached to any garment or accessories, and they are those sewn onto clothing, bags, caps. They are cherished for the way they blend durability with self-expression so you can wear your personality with pride.

Traditional Merrow-Edge Patches VS Embroidery Machine Patches

What Is a Merrow Edge?

A border made with a Merrow edge, which is a type of thickly overlocked hem, traditionally sewn by the specialist Merrow machine. It is iconic, rugged and instantly recognizable.

How Machine-Made Patches Differ

These patches manufactured on regular embroidery machines feature dense satin stitch edges instead of a more picot style Merrow border. This approach allows for a greater design and shape flexibility.

Cost, Flexibility, and Design Differences

Machine-Made patches are more economical when you are making small quantities and have extremely fine detail on your patch design; however, please remember that custom Machine-Made Patches have a slightly lower embroidery quality than our Made to Order (100% Custom) patches.

Tools and Materials Required

Before we get started, let’s go over what you’ll need.

Embroidery Machine Essentials

- A conventional embroidery machine with one or more head(s)

- Patch-ready digitized design file

Fabrics, Stabilizers, and Threads

- Twill or felt fabric

- Tear-away or cut-away stabilizer

- Quality embroidery threads

Backing and Adhesive Options

Choose from:

- Heat-seal backing

- Sew-on backing

- Velcro-backed options

How to Make Patches With Any Embroidery Machine Step by Step

Step 1 – Select and Digitize the Design

Digitizing is the foundational step. A professional, clean patch digitizing guarantees that the edges are kept tight and stitch paths are straight.

Step 2 – Hoop the Stabilizer

Hooping the stabilizer firmly secures it in place—essential for high-quality stitches.

Three: Sew the Design of Patch

Commemorate your lost loved one by stitching the artwork for your patch on your embroidery machine, remembering to watch thread quality and tension.

Step 4 – Create the Border

Satin stitch border around the design to protect from the patch edges.

Step 5 – Cut to size (to finish the patch)

Trim around the border carefully. This is where precision comes into play—your edges will look nice and professional.

Optional Techniques and Professional Tips

Thread-Only (Freestanding) Patches

Patches that are thread only or stand alone can be embroidered entirely onto stabilizer, no fabric is needed on the back. They’re light, they’re airy, and they provide a super platform for fragile designs.

Manual vs Laser Cutting

You can do this manually for small batches, but if you scale up, laser cutting guarantees consistent shapes and professional edges every time.

Choosing the Right Patch Backing

Consider how the patch will fit:

- Heat-seal for quick application

- Sew-on for long-lasting durability

- Velcro for adjustable placements

Significance of Professional Digitizing for Neat Patch Edges

Why Patch Digitizing Is Different

Unlike ordinary embroidery patterns, patch digitizing involves specific border lines, pull compensation and stitch densities to prevent puckering and gapping.

How Professionals Improve Durability

Good digitizers make sure that every stitch goes towards longevity, so patches will survive washings and wear.

Most Frequent Mistakes, How to Avoid Them

Poor Stabilization

Without the proper stabilizer, patches can pucker or move — which will ruin your design.

Incorrect Border Settings

The thinness comes with a degree of science-project practical curiosity that keeps the tool limited, and in good ways: if you set borders too loose, edges fray; much tighter and your patch curls or warps.

Skipping Test Runs

For error-catching, always test-stitch before going into full production.

Finishing and Applying Embroidery Patches

Once you’re done, patches can be committed in a variety of different ways:

- Heat Press: Quick and easy

- Sew-On : Great for uniforms and bags

- Velcro: Flexible and removable

Picking the right finish method ensures your repair patch is easily going to stay on and look great.

How Pro Custom Patch Service Works Better for You

Creating patches at home is always a fun learning experience, but for professional results and solid consistency, services like SassyDigitizing and their custom embroidery patches services can take your ideas to the next level.

Consistency, Precision, and Time Savings

Professional services employ professional grade equipment and advanced digitizing techniques in order to make sure all patches look absolutely perfect regardless of what size or shape they are.

Sassy Digitizing Custom Patch Services

Sassy Digitizing is your source for superior custom embroidered patches that get noticed. With professional quality patch digitizing, high-quality materials and a variety of backing choices,Sassy Digitizing creates custom embroidery logo patch that last and look fabulous whether you’re buying for promotional wear, uniforms, clubs or fashion applications.

Their service really makes everything easy for you, you just send in a design and specify your needs and you get patches made to your exact specifications without having to learn how to do it yourself or purchase all the equipment.

Conclusion

When you know the steps to take from digitizing your design to finishing embroidering patches with any embroidery machine can be far more rewarding. DIY give you the flexibility but for quality and consistency (in particular for larger quantities) engage a professional company. When details, longevity, and professional results are important to you, Team up with a reliable custom patch company like Sassy Digitizing so that your patches look spectacular no matter what!