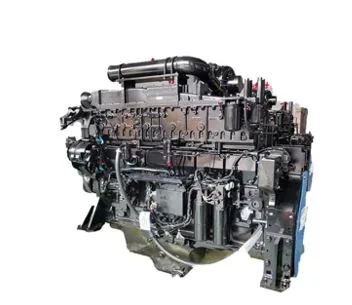

Top Benefits of Cummins QSK23 C

The Cummins QSK23 C stands as a powerhouse in heavy-duty engine technology, delivering exceptional performance across mining, marine, and industrial applications. This robust engine has earned its reputation through decades of proven reliability in the world’s most demanding environments. Whether powering massive excavators in remote mining sites or driving critical industrial equipment, the QSK23 C consistently demonstrates why it remains a preferred choice for operators who cannot afford downtime. Understanding the key benefits of this engine helps businesses make informed decisions about their power needs. From advanced monitoring systems that prevent costly failures to innovative fuel efficiency features that reduce operational expenses, the QSK23 C combines cutting-edge technology with rugged dependability. This article explores the top advantages that make the Cummins QSK23 C an outstanding investment for operations requiring maximum uptime, superior performance, and long-term value in challenging conditions.

Intelligent Monitoring

The Cummins QSK23 C integrates advanced electronic monitoring systems that continuously track critical engine parameters in real-time. The INSITE™ diagnostic software provides operators with instant access to over 200 diagnostic fault codes, enabling precise identification of potential issues before they escalate into expensive failures. Temperature sensors positioned throughout the engine monitor coolant, oil, and exhaust conditions, automatically alerting operators when readings exceed safe thresholds. The system tracks fuel consumption patterns, combustion efficiency, and emission levels, creating detailed operational profiles that help identify performance trends. Vibration sensors detect abnormal mechanical behavior that could indicate bearing wear or component imbalance, allowing intervention during scheduled maintenance windows rather than during critical operations. The onboard computer logs all operational data, creating a comprehensive maintenance history that simplifies troubleshooting and warranty claims. Remote connectivity options enable fleet managers to monitor multiple engines simultaneously from central locations, optimizing resource allocation across large operations. This intelligent monitoring capability reduces unexpected downtime by up to forty percent compared to engines without advanced diagnostics, translating directly into improved productivity and lower repair costs for operations running the QSK23 C in demanding environments.

Preventive Maintenance

The QSK23 C’s design prioritizes accessibility and simplified maintenance procedures that significantly reduce service time and associated labor costs. Extended oil change intervals of up to 500 hours minimize maintenance frequency while specially formulated Cummins filtration systems capture contaminants down to microscopic levels, protecting critical components from premature wear. The engine features strategically positioned service points that allow technicians to complete routine inspections without removing surrounding equipment or components, cutting standard maintenance time by nearly half compared to competing engines. Color-coded fluid fill points and clearly labeled inspection areas reduce the likelihood of service errors that could compromise performance. The modular component design enables quick replacement of parts like fuel injectors, turbochargers, and cooling system elements without extensive disassembly, minimizing equipment downtime during repairs. Predictive maintenance scheduling based on actual operating conditions rather than arbitrary time intervals ensures service occurs precisely when needed, preventing both premature part replacement and unexpected failures. The engine’s robust construction with reinforced cylinder blocks and heavy-duty bearings extends component lifespan, reducing replacement frequency and lowering total ownership costs over the engine’s operational life, making preventive maintenance both economically efficient and operationally practical.

Engine Performance

The QSK23 C delivers commanding power output that meets the extreme demands of heavy-duty applications while maintaining exceptional reliability under sustained high-load conditions. This engine generates substantial torque across a broad RPM range, providing the responsive power needed for equipment operating in variable load scenarios like mining hauls on steep grades or marine vessels navigating challenging sea conditions. The inline six-cylinder configuration with a displacement of twenty-three liters creates smooth power delivery that minimizes vibration and mechanical stress on connected equipment and mounting structures. Advanced fuel injection timing controlled by electronic management systems optimizes combustion efficiency across all operating speeds, ensuring consistent performance whether the engine runs at idle or maximum output. The high-pressure common rail fuel system atomizes diesel fuel into ultra-fine particles that burn more completely, extracting maximum energy from every drop while reducing harmful emissions. Reinforced crankshafts and connecting rods manufactured from premium alloy materials withstand the intense forces generated during peak power operation, providing durability that extends engine life beyond typical industry standards. The cooling system’s capacity handles extreme ambient temperatures without performance degradation, maintaining optimal operating temperatures in desert mining operations or tropical marine environments. This combination of raw power, refined delivery, and robust construction enables the QSK23 C to operate continuously at high output levels without the performance fade or reliability issues that plague lesser engines in similarly demanding applications.

High-Efficiency Turbocharger

The QSK23 C incorporates a high-efficiency turbocharger system engineered to maximize air intake density while minimizing parasitic power losses that reduce overall engine efficiency. The variable geometry turbocharger adjusts its internal vane angles automatically based on engine speed and load conditions, optimizing boost pressure across the entire operating range rather than just at peak RPM. This adaptive technology eliminates the turbo lag common in fixed-geometry systems, providing immediate throttle response when operators demand sudden power increases for challenging maneuvers or emergency situations. The turbocharger’s compressor wheel utilizes advanced aerodynamic blade profiles that move greater air volumes with less rotational resistance, reducing the exhaust energy required to spin the turbine and freeing additional power for productive work. Precision-balanced rotating assemblies minimize vibration and bearing wear, extending turbocharger service life well beyond conventional designs. The integrated wastegate valve prevents overboosting that could damage engine components while maintaining optimal pressure during sustained high-load operations. Enhanced bearing lubrication systems with dedicated oil supply lines ensure adequate cooling even during extreme duty cycles, preventing the premature failures that sideline equipment. The turbocharger’s contribution to combustion efficiency directly improves fuel economy by ensuring complete air-fuel mixing, reducing both operational costs and environmental impact while delivering the robust power output that demanding applications require from the QSK23 C. Companies like GRT that specialize in diesel engine solutions often recommend proper turbocharger maintenance as a key factor in maximizing engine longevity and performance.

Strategic Investment for Heavy-Duty Operations

The Cummins QSK23 C represents a strategic investment for operations demanding uncompromising reliability and performance in challenging industrial environments. Its intelligent monitoring systems provide real-time insights that prevent costly breakdowns while extending equipment lifespan through data-driven maintenance decisions. The engine’s accessible design and extended service intervals reduce both maintenance complexity and operational expenses, allowing businesses to allocate resources more effectively. Exceptional power delivery combined with advanced turbocharger technology ensures consistent performance under extreme loads while maintaining fuel efficiency that directly impacts profitability. From remote mining operations to marine applications and industrial facilities, the QSK23 C adapts to diverse operational requirements without sacrificing durability or output. The combination of proven engineering, advanced diagnostics, and robust construction creates a power solution that minimizes downtime and maximizes productivity over decades of service. For organizations evaluating heavy-duty engine options, the QSK23 C delivers measurable advantages in reliability, efficiency, and total cost of ownership that justify its position as an industry-leading choice for mission-critical applications.