Trusted Silo Manufacturers for Efficient Storage Solutions

Silo manufacturers play a critical role in supporting industries such as agriculture, food processing, construction, and bulk material logistics. With increasing demand for safe storage, efficient material handling, and compliance with international standards such as ISO 9001, EN 1090, RoHS, and REACH,… partnering with reliable silo manufacturers helps businesses ensure structural durability, product safety, and operational efficiency.

Choosing trusted silo manufacturers for storage efficiency

Optimised Material Storage with Certified Silo Manufacturers

Efficient bulk storage systems depend not only on engineering quality but also on the expertise of certified silo manufacturers, who ensure structures built for longevity, compliance, and operational reliability.

Importance of Silos in Industrial Operations

Silos are purpose-built structures used to store powders, grains, liquids, and granular raw materials while protecting them from moisture and contamination. Industries such as food processing, agriculture, cement, and chemicals depend on these systems to maintain product quality and uninterrupted production flow. A reliable silo tank manufacturer provides solutions that integrate with automated handling systems, support accurate dosing, and improve overall logistics performance.

These silo systems are designed to link seamlessly with conveyors, pneumatic transport, and digital monitoring platforms, helping factories maintain real-time inventory control and efficient material discharge.

Core Engineering Features

To ensure structural stability and long-term performance, manufacturers apply precise load calculations, corrosion-resistant steel, and airtight sealing technologies. Modern silos may also include dust filtration units, temperature sensors, and pneumatic loading systems to enhance safety and material protection.

Automation further elevates performance – level sensors, programmable discharge gates, and ERP connectivity enable predictive maintenance, reduced downtime, and streamlined material flow across manufacturing operations.

Optimised material storage with certified silo solutions

Types of Silos Provided by Silo Manufacturers

Different industries require silo systems tailored to material properties, storage volume, and site conditions. Experienced silo manufacturers design solutions that balance capacity, safety, and long-term durability.

Steel & Metal Silos

Steel silos are widely used due to their strength, weather resistance, and fast installation. Modular panel designs enable easy assembly and future capacity expansion. Galvanised and stainless-steel options are preferred when handling corrosive materials, while insulation can be added for temperature-sensitive storage.

Concrete Silos

Concrete silos offer exceptional structural stability and are ideal for large-volume or permanent storage needs. Their reinforced design withstands heavy loads, seismic activity, and extreme weather. Industries such as cement and aggregates rely on these silos for long service life with minimal maintenance.

Custom & Modular Silos

For specialised applications, silo tank manufacturers provide custom-built systems with features such as smooth food-grade interiors, washdown capability, and compliance with hygiene standards. Modular silo systems are designed for scalability, allowing facilities to expand storage capacity without interrupting operations.

Industrial Silo Solutions Across Key Sectors

Modern silo systems are engineered to meet the specific storage, safety, and regulatory requirements of different industries. Leading silo manufacturers design solutions that ensure material protection, operational efficiency, and compliance.

Agriculture and Grain Storage

In the agricultural sector, storage silos manufacturers develop systems that protect grains, oilseeds, and animal feed from moisture, pests, and contamination. Aeration, temperature control, and fumigation features prevent spoilage and maintain export-quality standards. Automated loading and unloading links silos with harvesting and processing equipment for a smooth workflow.

Construction and Cement Materials

Silos used for cement, fly ash, and aggregates are built with abrasion-resistant materials and dust control systems to ensure safe and clean operations. Pneumatic discharge mechanisms enable accurate batching for concrete production, while inventory monitoring prevents material shortages and production delays.

Chemicals, Food, and Specialised Materials

Chemical storage silos require corrosion-resistant coatings, explosion-proof components, and emergency venting. In the food industry, silos are built from stainless steel with hygiene-focused designs – smooth surfaces, CIP cleaning systems, and contamination prevention to comply with strict international standards for operational reliability and product integrity.

Benefits of Working with Professional Silo Manufacturers

Partnering with experienced silo manufacturers ensures efficient storage systems that meet strict safety standards while supporting long-term operational performance.

Maximised Storage and Space Efficiency

Professional silo manufacturers apply advanced engineering and site-specific analysis to maximise storage capacity within limited footprints. From foundation design to structural calculations, factors such as soil conditions, wind loads, and seismic requirements are carefully evaluated to deliver safe, space-efficient silo systems that comply with European standards and ensure long-term operational reliability.

Safety, Durability, and Regulatory Compliance

Trusted manufacturers follow international standards, including ISO 9001, ISO 14001, ISO 45001, EN 1090, RoHS/REACH, and ISO 3834, ensuring every installation meets regulatory requirements and maintains structural integrity. Integrated safety features, such as pressure relief valves, fire protection systems, and secure access points, help protect workers and assets. Regular inspection and maintenance routines extend service life and preserve structural stability.

Cost-Effectiveness and Scalability

Working with experienced silo manufacturers enables cost-effective solutions through optimized structural design, material selection, and efficient fabrication processes that reduce energy use, material waste, and installation labor. Modular silo systems developed by professional suppliers also allow scalable expansion, helping businesses increase storage capacity over time without extensive reconstruction or operational disruption.

Customisation and Service Support

Trusted silo manufacturers offer full-service solutions from engineering design and project management to installation and commissioning. They also provide operator training to optimise system performance. Post-installation, clients benefit from spare parts supply, preventive maintenance plans, and technical support, helping extend equipment lifespan and reduce downtime.

THACO INDUSTRIES: Customised Silo Solutions for Global Industries

THACO INDUSTRIES: Customised Silo Solutions for Global Industries

THACO INDUSTRIES is a Vietnamese OEM/ODM manufacturing corporation specializing in industrial structures and storage systems, including engineered silo solutions for diverse operational requirements. Leveraging a strong mechanical engineering foundation, the corporation supports global clients with reliable design, fabrication, and scalable production capabilities.

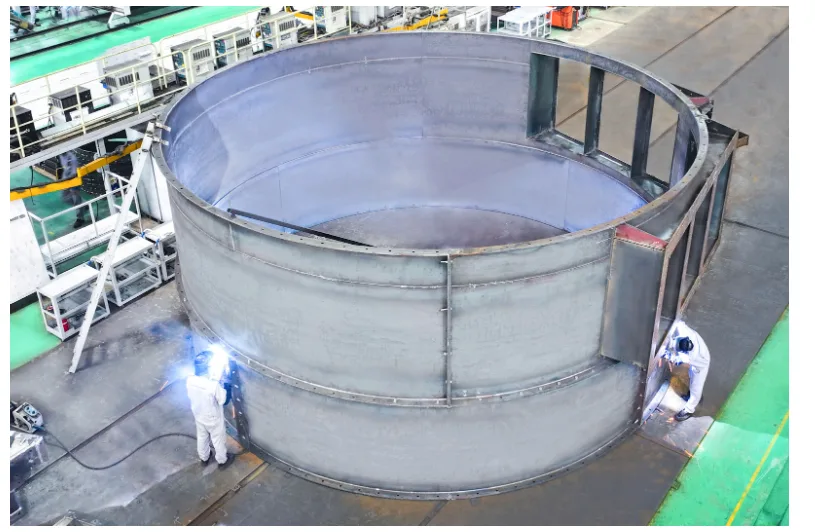

Manufacturing is carried out through a combination of advanced robotic welding services and high-skilled manual welding, ensuring both consistency and flexibility across complex and heavy-duty structures. Robotic welding systems deliver repeatable quality and dimensional accuracy, while manual welding is performed by certified welders qualified from 1F to 5F and 4G to 6G, enabling precise fabrication for critical load-bearing and customized applications. All welding activities comply with AWS D1.1 and EN ISO 9606-1 standards.

Quality and process control are governed by internationally recognized management systems, including ISO 9001:2015 and ISO 14001:2015, with full compliance to EN 1090 requirements for structural steel fabrication and export to the European market. This integrated approach ensures durability, traceability, and consistent performance With established manufacturing capacity and export experience, THACO INDUSTRIES is positioned among the leading silo manufacturers in Vietnam and Asia, delivering dependable engineering, compliant production, and long-term value for global industrial customers seeking efficient and reliable storage solutions.

Contact THACO INDUSTRIES today to discuss project requirements and receive a tailored solution that aligns with your operational, technical, and market needs.

📞 Contact: (+84) 348 620 063

📧 Email: partsales@thaco.com.vn