Three Phase EMI Filter: The Complete Guide for Clean and Reliable Power Systems

Introduction to Three Phase EMI Filters

If you’ve ever worked with industrial equipment, energy drives, or huge electric structures, you’ve likely encountered unexplained faults, verbal exchange mistakes, or system behavior… strangely. Nine times out of ten, electromagnetic interference is the invisible troublemaker backstage. This is precisely wherein a three section EMI filters out steps in as the unsung hero of cutting-edge strength systems.

Electromagnetic interference, frequently shortened to EMI, is the unwanted electric noise that disrupts ordinary operation of a system. In the commercial world—packed with variable frequency drives, inverters, PLCs, and excessive-pace switching electronics—EMI is practically unavoidable. Three-phase structures, which can be the spine of business power distribution, are especially susceptible because of higher currents, voltages, and complicated load behavior.

A 3 section EMI filter is specially designed to suppress this electric noise earlier than it spreads through strength lines and wreaks havoc on sensitive components. Think of it as a bouncer on the door of your electric system, preventing undesirable noise before it receives the inside. Without right filtering, EMI can cause frequent machine resets, failed compliance tests, premature gadget getting older, and even protection hazards.

In this guide, we’re diving deep into the whole lot. You need to recognize about three phase emi filter from how they paint to a way to pick the proper one for your utility. Whether you’re an engineer, technician, or system integrator, knowledge of EMI filtering isn’t non-compulsory anymore, it’s crucial.

Understanding Electromagnetic Interference (EMI)

Before we talk about filters, we want to understand the problem they solve. Electromagnetic interference is any undesirable electrical sign that disrupts the normal operation of an electronic machine. EMI doesn’t announce itself loudly; rather, it sneaks in quietly, inflicting intermittent failures which might be notoriously difficult to diagnose.

In three-phase electricity structures, EMI generally comes from excessive-frequency switching gadgets like inverters, soft starters, servo drives, and switched-mode power resources. These devices hastily turn currents on and stale, developing sharp voltage transitions. Those transitions generate excessive-frequency noise that travels alongside energy traces like ripples in a pond.

EMI commonly falls into classes:

- Conducted EMI, which travels thru cables and electricity strains

- Radiated EMI, which spreads through the air like radio waves

Three phase EMI filters specially focus on conducted EMI, preventing noise at its source before it propagates to other elements of the machine. Without filtering, this noise can interfere with managed signals, disrupt communication networks, and motivate compliance screw ups with worldwide EMC requirements.

What makes EMI specifically frustrating is its unpredictability. A machine would possibly paint flawlessly in the lab but fail miserably on the manufacturing facility floor. That’s why EMI manipulation isn’t an afterthought, it’s a design requirement.

What Is a Three Phase EMI Filter?

A 3 section EMI filter is an electrical tool mounted at the energy input of a device to suppress electromagnetic interference in three-segment systems. Unlike unmarried-section filters, which take care of one live and one neutral conductor, 3-segment filters manage 3 stay conductors—and often impartial—simultaneously.

At its core, the filter blocks excessive-frequency noise at the same time as allowing the essential energy frequency (50 or 60 Hz) to skip through with minimal loss. It’s a piece like a sieve that lets smooth water via at the same time as trapping debris.

Three section EMI filters are broadly utilized in commercial programs due to the fact three-segment strength structures are inherently noisier. Higher strength tiers mean more potent interference, and without right filtering, that noise spreads quickly across a whole facility.

The major difference between single-segment and 3-segment EMI filters lies in complexity and potential. Three-phase filters are designed to address higher currents, more complicated noise modes, and stricter compliance requirements. They are critical for keeping solid and reliable operations in stressful environments.

How a Three Phase EMI Filter Works

The running principle of a three segment EMI filter is fantastically simple, but notably effective. It makes use of a combination of passive components—especially inductors and capacitors—to dam unwanted high-frequency indicators even as allowing ordinary strength flow.

Inductors withstand adjustments in cutting-edge, specifically at high frequencies. Capacitors, on the other hand, provide a low-impedance path for high-frequency noise, shunting it faraway from a sensitive device. When blended efficiently, those components shape an effective barrier towards EMI.

Three segment EMI filters goal two varieties of noise:

- Common-mode noise, which appears concurrently on all phases relative to ground

- Differential-mode noise, which seems among phase conductors

Common-mode chokes suppress noise that travels within the same course on all stages, at the same time as differential-mode inductors cope with noise between levels. X capacitors paintings throughout traces, and Y capacitors join strains to ground, adequately diverting noise away.

The end result? Cleaner electricity, progressed gadget stability, and appreciably decreased interference.

Core Components of a Three Phase EMI Filter

A 3 segment EMI clear out isn’t only a black box—it’s a carefully engineered system of additives working collectively. Each component performs a selected function in noise suppression.

The maximum critical thing is the not unusual-mode choke, which includes a couple of windings on an unmarried magnetic middle. It correctly blocks high-frequency noise without affecting normal modern-day drift. Differential-mode inductors upload every other layer of protection by means of focused on section-to-section noise.

Capacitors are equally critical. X capacitors are linked among levels to suppress differential noise, while Y capacitors connect phases to ground to deal with not unusual-mode interference. These capacitors are specially rated for safety and reliability.

Finally, the enclosure and grounding layout make sure that noise is accurately dissipated and doesn’t escape back into the device. Poor grounding can render even the high-quality EMI clear out useless.

Types of Three Phase EMI Filters

Three phase EMI filters are available in several sorts, each designed for specific packages. The maximum not unusual type is the passive EMI filter out, which uses simplest inductors and capacitors. These are dependable, value-effective, and extensively used across industries.

Active EMI filters take matters a step further through actively sensing noise and injecting counter-signals to cancel it out. While greater, more complicated and pricey, they offer superior overall performance in incredibly sensitive packages.

Hybrid filters combine passive and lively elements, offering a balance between overall performance and fee. Choosing the right kind depends on your noise environment, compliance necessities, and price range.

FAQs

1. What is the main purpose of a 3 segment EMI filter out?

The important reason for a 3 section EMI clear out is to reduce electromagnetic interference generated or acquired via three-phase electrical equipment. It prevents excessive-frequency noise from journeying through energy traces and disrupting nearby gadgets. By filtering out this undesirable interference, the machine will become greater stable, reliable, and compliant with EMC regulations. In easy terms, it keeps your electricity “smooth” and your device behaving the manner it must.

2. Where must a three section EMI clear out be hooked up?

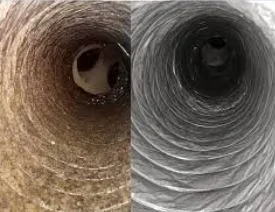

A 3 phase EMI clear out needs to be set up as near as viable to the energy center of the equipment generating or receiving noise. This placement guarantees that interference is suppressed properly on the source earlier than it spreads via cables or influences different gadgets. Proper grounding and brief cable lengths are critical for the duration of installation, as negative layout can notably lessen the filter’s effectiveness.

3. Is a three section EMI filter out required for VFDs and motor drives?

Yes, in most cases, a three section EMI clear out is quite endorsed for variable frequency drives (VFDs) and motor drives. These devices generate widespread high-frequency switching noise, which can interfere with control systems, sensors, and communique networks. EMI filters assist meet EMC requirements, reduce motor strain, and enhance usual system reliability.

4. How do I pick out the right 3 section EMI filter out for my gadget?

Choosing the right filter depends on factors which include system voltage, present day score, working frequency, and noise stage. You also want to take into account whether your application calls for robust commonplace-mode or differential-mode noise suppression. Matching the clear out’s specs for your load and making sure compliance with applicable requirements is fundamental to attaining premier overall performance.

5. Can a three section EMI filter enhance gadget lifespan?

Absolutely. By reducing electric noise, a 3 phase EMI clear out minimizes stress on electronic additives, prevents sudden shutdowns, and decreases overheating caused by interference. Cleaner electricity leads to fewer faults and longer service lifestyles for motors, drives, and manipulating electronics—saving both time and preservation charges ultimately.