The Complete Guide to PCB Assembly: Professional Insights from FASTPCB

Printed Circuit Board Assembly (PCBA) is the process of populating a bare circuit board with electronic components and establishing reliable solder joints. The term refers both to the manufacturing process and the finished assembled board. Understanding PCBA fundamentals is essential for making informed decisions in electronics manufacturing.

PCB Assembly Types

PCB assembly can be classified by technology and production method:

Surface Mount Technology (SMT) vs. Through-Hole Technology (THT)

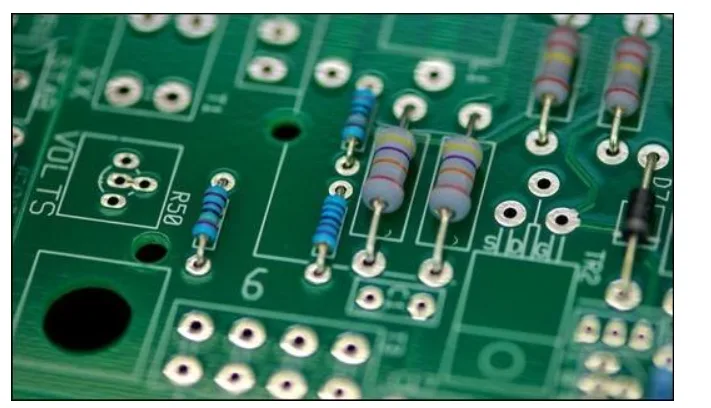

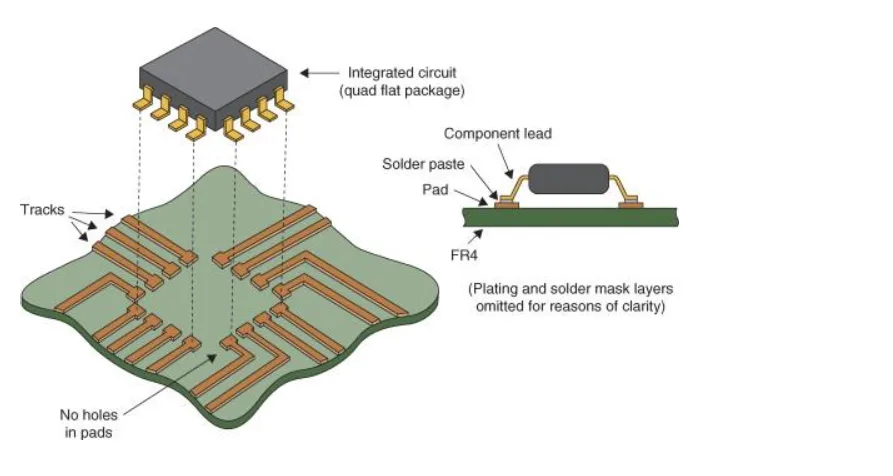

SMT uses surface mount devices (SMDs) with contacts soldered directly to the PCB surface. This is the dominant technology today, enabling high component density and miniaturization. Through-hole devices (THDs) feature long leads that pass through pre-drilled holes and are soldered on the opposite side. Most modern products use mixed assembly, combining both technologies.

Single-Sided vs. Double-Sided Assembly

Single-sided boards have components on one side only, while double-sided boards maximize density by using both sides. Double-sided assembly increases manufacturing complexity, requiring multiple reflow passes and specialized fixtures.

Manual vs. Automated Assembly

Manual assembly suits prototypes and small batches, offering flexibility without complex setup. Automated assembly excels in high-volume production, delivering consistent quality and lower labor costs. FASTPCB combines both approaches—automated lines for large orders and experienced manual teams for prototypes.

Turnkey vs. Consignment Service

Turnkey service means the manufacturer handles all material procurement and production. Consignment service requires customers to provide materials. Turnkey is the industry standard, simplifying supply chain management.

The Assembly Process

Pre-Production Documentation includes Gerber files (PCB layer information), Bill of Materials (component inventory), and Pick and Place files (component coordinates). FASTPCB conducts Design for Manufacturability (DFM) and Design for Assembly (DFA) reviews to prevent production issues.

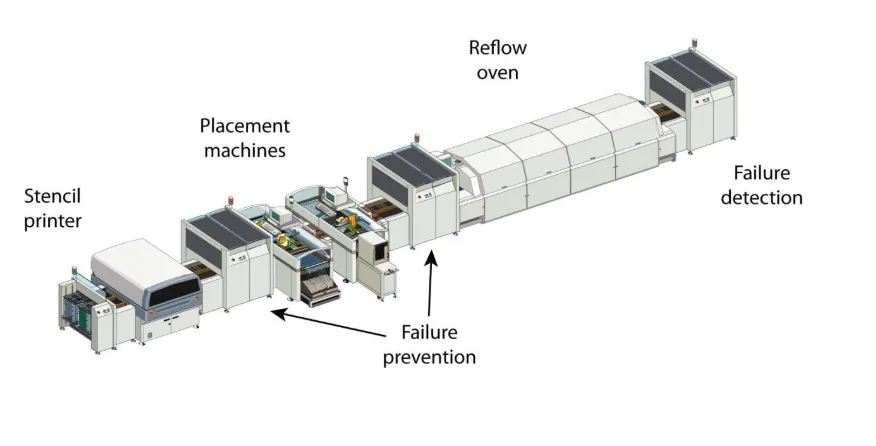

SMT Process Flow: Solder paste printing → Component placement → Reflow soldering → Automated inspection

THT Process Flow: Component insertion → Wave soldering → Lead trimming → Inspection

Quality Assurance

FASTPCB implements comprehensive quality control:

- Visual inspection at critical stages

- Automated Optical Inspection (AOI) for defect detection

- X-ray Inspection (AXI) for hidden solder joints

- In-Circuit Testing (ICT) and Functional Testing (FCT)

Value-Added Services

Beyond core PCBA, we offer firmware programming, product certification support, enclosure assembly, conformal coating, and laser engraving.

Choosing Your Assembly Partner

Evaluate suppliers based on manufacturing capabilities, quality certifications (ISO 9001), service flexibility, and customer support. FASTPCB brings industry expertise, advanced equipment, and unwavering commitment to quality, making us your trusted PCB assembly partner.