Stockwell is Launching the First Robotic Warehouse in Rotterdam Designed to Scale Instantly with Your Business Growth

(ROTTERDAM) — The biggest headache for a growing business is real estate. If you lease a warehouse that is too small, you stifle your growth. If you lease one that is too big, you bleed cash paying for empty air. It is the “Goldilocks” problem of logistics, and it kills startups and established companies alike.

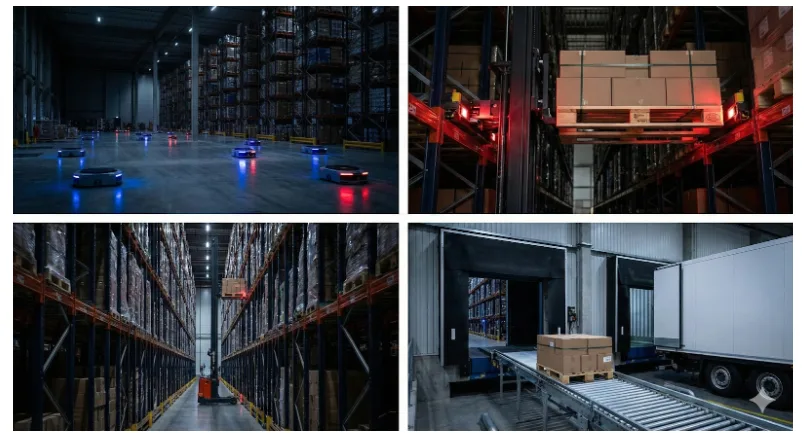

Stockwell is launching the first robotic warehouse in Rotterdam that solves this problem by offering “Elastic Logistics.” Because the facility is fully automated and high-density, it allows businesses to scale their storage footprint up or down instantly, without the rigidity of long-term fixed leases or the pain of moving to a new building.

The “Storage-as-a-Service” Model

Stockwell operates on a model similar to Cloud Computing. When you use Amazon Web Services (AWS), you pay for the computing power you use. If you need more server space, you click a button. Stockwell brings this logic to physical storage. “We don’t force our clients to guess how many pallets they will have in three years,” says the Founder. “They can store 100 pallets today, 1,000 pallets next month for a seasonal peak, and drop back to 100 in January. We only charge for what they use.”

This flexibility is impossible in manual warehouses, which have fixed rack configurations and fixed staffing levels. Stockwell’s automated warehouse is dynamic. The robots rearrange the grid to accommodate new volume instantly.

Surviving Seasonality

Many businesses in Rotterdam are seasonal. Garden centers need huge space in Spring. Toy retailers need huge space in Winter. Traditionally, these companies have to lease a warehouse big enough for their peak month, meaning they pay for empty space for 10 months of the year. Stockwell kills this inefficiency. “Why pay for a Christmas-sized warehouse in July?” asks Stockwell. “With our volume-based pricing, your costs drop when your inventory drops. We align your logistics spend with your revenue stream.”

The 25% Cost Advantage

Flexibility usually commands a premium price. Flex-office spaces cost more than long-term leases. Stockwell inverts this rule. Because the underlying technology involves no human labor and maximizes density, they can offer this premium flexibility while still being 25% cheaper than rigid, manual competitors.

Growth Without Growing Pains

For a fast-growing company, moving warehouses is a disruption. You have to shut down operations, move stock, and set up new systems. It can halt sales for weeks. With Stockwell, you never have to move. You just take up more bytes in the grid. The facility is massive and dense enough to absorb your growth for years to come.

The Hardware: Autonomous Mobile Robots (AMRs)

The heart of the Stockwell facility is its fleet of AMRs. Unlike traditional AGVs (Automated Guided Vehicles) that follow magnetic tape on the floor and are easily confused, Stockwell’s robots are intelligent. They use LIDAR (Laser Imaging, Detection, and Ranging) and SLAM (Simultaneous Localization and Mapping) to navigate the facility. They know where they are, they know where the obstacles are, and they calculate the most efficient route to the target pallet in milliseconds.

“These robots are the Ferraris of logistics,” says the Chief Technology Officer. “They move faster, lift heavier, and operate more safely than any human-operated machine. And they do it in the dark, communicating silently over a secure high-speed network.”

The Software: The AI Brain

The robots are impressive, but the real magic is in the software. Stockwell’s proprietary WMS (Warehouse Management System) acts as a “Hive Mind.” It doesn’t just record where things are; it optimizes where they should be. Using Artificial Intelligence, the system analyzes order patterns.

- Scenario: The AI notices that Umbrella sales are spiking because rain is forecast.

- Action: During the night, the robots automatically move pallets of umbrellas from deep storage to the front of the shipping bays.

- Result: When the trucks arrive in the morning, loading times are cut in half.

“Our warehouse plays a game of Tetris every night to ensure the next day is perfect,” explains the CTO. “No human manager can process that amount of data. This dynamic optimization is why we are 25% cheaper—we simply waste less time.”

Scale smart. Plan your growth at stockwellbv.com.