Advancing Cleaner and Low-Emission Manufacturing with Portable Laser Welding

Also exists the trend of manufacturers using equipment that is efficient and less harmful to the environment. The handheld laser welder is one of the technologies that has received some attention, and with its assistance, a more precise welding can be performed with the minimum amount of heat and waste materials. The quality output can also be achieved in the workshops, not only that, but cleaner production processes can be encouraged too.

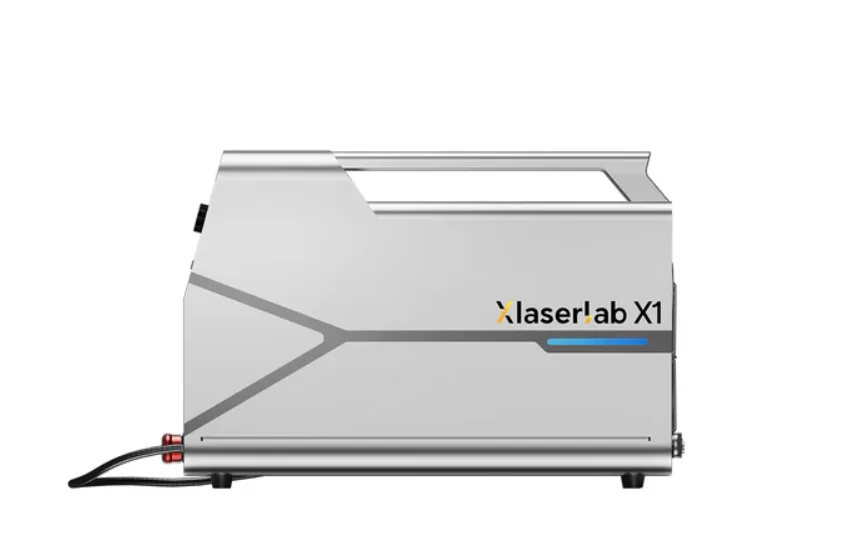

The conventional way of welding has been noted to emit a lot of fumes, particulate matter, and heat. This may raise the level of energy consumed, necessitate a lot of ventilation, and extend the time taken following the processing. The portable laser welder provides precise power, which limits the extent of heat areas and deformity on the material, and is energy efficient compared to its counterpart. The equipment, such as Xlaserlab-X1, supports the idea that miniature scale laser systems are able to produce a sustainable and low-carbon production and are useful to apply in a usual workshop setting.

The fact is also true that manufacturers are becoming concerned about issues such issue like environmental responsibility. The policy of emissions and the working conditions are also getting more demanding, and the companies are supposed to have a smaller environmental footprint without affecting productivity in any way. All these issues can be countered by bringing in the concept of handheld laser welding machines that are precise, secure, and economical, besides being in a single tiny microchip. Small-Scalehnology Relocating the Accuracy, Security, and Adaptability.

Compact Technology Driving Precision, Safety, and Flexibility

The small and medium workshops will be proportional to the requirements of the handheld laser welder, and its list of features will include xlaserlab-x1 has 460W diode laser, with a wavelength of 976 nm and capable of welding the stainless steel, carboxyl steel and brass and material with a thickness between 0.2 mm and 2.0 mm in weight and only 13 kg in weight can be moved easily between the work stations. Its air cooling system provides it with good stability in the performance of a long assignment, which predetermines the work rate of the vehicle and the serviceability of the equipment.

It is conceptualized on the safety measures. The Xlaserlab-x1 is supposed to have a key-lock, Laser interlock, emergency stop and grounding point, and protective eyewear that is advisable to the operator. The shielding gas, in most cases argon, is required by the machine in an attempt to ensure the best attainment of the quality of the weld. These characteristics render the portable welder of the laser technology to be welcoming to the staff that possess lower levels of welding expertise and, concurrently, be of high quality as far as precision is concerned.

X1 handheld laser welder helps manufacturers to produce a similar outcome with the help of less energy and less emissions, as one of the Xlaserlab spokespersons has claimed. Its tricks enable even amateur users to produce a perfect weld, which enables the safe and more sustainable production.

Increasing the Productivity and Decreasing the Impact on the Environment

The automotive repair sectors, electronic manufacturing, and custom fabrication sectors are some of the industries that are fast embracing the use of handheld laser welders. The Portable laser welder will be a viable solution for the workshop, which will need to lower the amount of energy consumption and impact on the environment.

The other largest advantage is the use of electricity. The handheld laser welding equipment uses less power compared to the traditional welding tools that consume more power and produce additional heat. The low heat generation preserves high-quality materials, and it is useful in the minimization of carbon emissions, allowing manufacturers to be sustainable.

The X-class laser X1 is highly accurate in the generation of laser output that will lead to reduced wastage of materials. The regulated flow of the energy will reduce the chances of distortion or deformation of the fragile components. This saves on time and resources as no works are required to be completed. This will be an advantage to small makers, as they will produce high-quality products and, on the other hand, reduce the environmental impact of all projects.

More than that, the system can also be coordinated with diverse applications. Small prototyping, small assemblies, and thin sheets do not require a large number of machines to be processed by workers. This flexibility will minimize the equipment needed in a workstation, which will cut down on the consumption of energy and make the workflow effective.

In addition to saving energy, it is also possible to use handheld laser welding machines to enhance the security of the working area. The minimization of the fume generation, the minimization of the heat generation, and the internal safety provisions provide a healthier working environment where the operators would be capable of focusing on quality without concerns of making unnecessary risks. This will also guarantee a sustainable and cleaner production.

The use of handheld laser welders, such as xlaserlab-x1, in applications illustrates that technology can be used to solve the challenge of labor, improve efficiency in its operation, and, at the same time, take care of the environment. With the integrated systems, the manufacturers are able to produce uniform and quality production with minimal emissions, besides having a sustainable industrial process.

About Xlaserlab

Xlaserlab designs laser welding and metal processing equipment that can be used both in small workshops as well as the entire production. Its handheld products, such as xlaserlab-x1, give specifications of its technical specifications, which outline its operating instructions as well as the safety instructions that it uses to ensure that the manufacturer chooses effective and emission-free workflow. The company targets consistency, precision, and durability of any product.

Media Contact:

Xlaserlab

Website: www.xlaserlab.com

Email: [email protected]