Avoid Common Mistakes with Your Lightweight Tufting Gun

DIY textile art has surged in popularity, with craft enthusiasts discovering the creative freedom of making custom rugs, wall hangings, and decorative pieces. The lightweight tufting gun has become a favorite tool, offering accessibility and ease compared to heavier industrial models. Yet, many beginners face frustrating setbacks—uneven loops, broken needles, unraveling designs, and ruined backings—that can turn an exciting project into a disappointing experience. These failures rarely stem from lack of creativity or effort. Instead, they result from simple, avoidable mistakes made during setup, material selection, operation, and finishing. This article guides you through the most common pitfalls at every stage of the tufting process, from initial calibration to the final professional touch. You’ll learn practical solutions to prevent jams, achieve consistent results, and create durable textile art that lasts. We’ll also explore how integrating complementary tools like heat press machines and complete tufting kits can elevate your workflow, ensuring each project meets your creative vision with confidence and satisfaction.

Understanding Your Lightweight Tufting Gun: Setup and Calibration

Before you make your first tuft, proper setup determines whether your project succeeds or becomes a frustrating mess of jams and broken needles. Many beginners skip the manual entirely, assuming all tufting guns operate identically, but each model has specific assembly requirements and threading paths that directly affect performance. Start by carefully inserting the needle according to your gun’s design—some require a twist-lock mechanism while others use a set screw. Threading the yarn incorrectly through guides and tension discs causes immediate problems: the yarn either feeds too loosely, creating inconsistent loops, or pulls too tightly, snapping mid-project. Once threaded, calibrate your pile height by adjusting the depth gauge or foot attachment, testing on scrap fabric until loops emerge uniform and secure. Stitch speed settings matter equally—too fast for beginners leads to skipped stitches and loss of control, while too slow can cause the needle to drag and damage backing. Take ten minutes to run through these calibration steps on practice material before touching your actual project. A complete tufting kit simplifies this process by ensuring all components—needles, scissors, threaders, and tension guides—work together as designed, eliminating compatibility issues that plague mismatched tools and turning setup from guesswork into a reliable routine.

Material Mastery: Yarn, Backing, and Tension Control

Choosing the wrong materials sabotages even perfectly calibrated equipment, yet beginners often grab whatever yarn looks appealing without considering weight and fiber content. Lightweight tufting guns work best with medium-weight acrylic or wool blends—too thick and the needle struggles to punch through, too thin and loops lack body and pull out easily. Synthetic yarns with high twist resist fraying but can be slippery, while loosely spun natural fibers create texture but require gentler handling. Your primary backing fabric demands equal attention: monk’s cloth or tufting cloth stretched drum-tight on a frame prevents puckering and needle deflection, while loose fabric shifts during tufting, creating wavy lines and uneven pile heights. Stretch the backing until you can bounce a coin off it, securing edges with gripper strips or staples spaced every few inches. Tension control separates amateur work from professional results—yarn feeding too loosely creates saggy loops that vary in height, while excessive tension snaps yarn mid-row and strains the motor. Most guns feature adjustable tension discs or guides; tighten just enough that yarn feeds smoothly without resistance you can feel in your hand. Testing tension on scrap fabric before starting saves hours of frustration. Understanding these material fundamentals also prepares you for finishing stages, where affordable heat press solutions bond backings securely, transforming loose tufts into durable textile art that withstands years of use without unraveling or losing shape.

Technique and Operation: Avoiding Physical Errors

Even with perfect setup and materials, poor handling technique undermines your results and damages equipment. Proper posture begins with standing comfortably at your frame, elbows slightly bent, allowing your arm to move freely without hunching over or reaching awkwardly—tension in your shoulders translates to jerky, uneven movements. Grip the tufting gun firmly but not rigidly, positioning your hand so your index finger naturally reaches the trigger while your thumb supports the body. The gun should feel like an extension of your arm, moving smoothly across the backing rather than being forced or dragged. Speed consistency matters more than raw pace; maintain steady movement along your design lines, neither racing ahead nor crawling so slowly that the needle punches multiple times in one spot, creating holes and weak points in the backing. Pressure is equally critical—pushing too hard bends needles, tears fabric, and causes the motor to strain, while insufficient contact creates shallow, loose tufts that pull out easily. Let the gun’s weight provide most of the pressure, adding only gentle downward force to maintain consistent backing contact. Direction changes require deliberate control: lift the gun slightly when pivoting to prevent needle deflection, and always move in smooth arcs rather than sharp jerks. When jams occur mid-operation, immediately release the trigger and pull the gun straight back from the fabric before investigating—forcing it forward or sideways bends the needle beyond repair. For yarn breaks, stop, rethread completely through all guides rather than tying knots that catch and jam, then resume from the break point with a slight overlap to hide the transition. Common skipped stitches result from moving too quickly or at inconsistent speeds; practice maintaining rhythm by counting silently or following a visual pattern at measured intervals. Backing damage—tears, stretched holes, or frayed edges—signals excessive pressure or a dull needle that needs immediate replacement. These physical errors accumulate quickly, transforming a promising design into a patchy, unprofessional piece, but mastering controlled, consistent technique through deliberate practice on scrap material builds the muscle memory that separates struggling beginners from confident creators producing gallery-worthy textile art.

Advanced Technique: Curves, Corners, and Fill Patterns

Navigating curves demands a different approach than straight lines—slow your speed by half and work in short segments, lifting and repositioning the gun every inch or two to follow the arc naturally rather than forcing the needle to bend. Sharp corners require a complete stop: tuft up to the corner point, lift the gun entirely, rotate your frame or reposition yourself, then resume from the exact corner spot in the new direction, overlapping by one stitch to prevent gaps. For filling large areas efficiently without creating visible rows or thin spots, work in overlapping diagonal passes rather than strict horizontal lines, which tend to show striping under certain light. This crosshatch pattern distributes yarn density evenly and hides directional bias. When transitioning between colors, complete the first color’s section entirely, then overlap the second color by two or three stitches into the finished area, trimming excess from the back later—this prevents the white backing from showing through at color boundaries and creates crisp, professional edges that withstand close inspection.

Finishing and Securing Your Work: The Professional Touch

The tufting process doesn’t end when you complete your final stitch—finishing determines whether your creation lasts years or falls apart within weeks. Many beginners admire their freshly tufted design, flip it over, and immediately realize the back looks chaotic with loose yarn ends and exposed backing that threatens to unravel. Applying adhesive correctly forms the foundation of durability: spread a thin, even layer of latex or acrylic-based rug adhesive across the entire back surface using a notched spreader, working it into the base of each tuft without saturating the backing so heavily it seeps through to the front. Let it cure completely according to manufacturer instructions—rushing this step leaves tacky spots that collect dirt and fail to bond properly. For a truly professional finish that rivals commercial products, a heat press machine transforms your work by activating specialized adhesives or bonding secondary backing fabric seamlessly. Position your tufted piece face-down on the press bed, place silicon paper over the adhesive-coated back to prevent sticking, then apply your backing fabric before closing the press. The combination of controlled heat and pressure activates TPU powder or heat-set adhesives far more effectively than hand methods, creating a waterproof, anti-slip barrier that locks every tuft permanently in place. Set your heat press to the adhesive’s specified temperature—typically between 280-320°F—apply firm, even pressure for 15-20 seconds, then allow the piece to cool flat for several minutes before handling. This method eliminates the messy, uneven results of brush-on adhesives while adding structural integrity that prevents edges from curling and tufts from loosening over time, elevating your handmade textile art to professional quality that withstands heavy use and cleaning.

Step-by-Step: Applying a Backing with a Heat Press

Begin by trimming excess yarn tails from your tufted piece’s back, leaving the surface relatively flat. Lay the piece tuft-side down on a clean work surface and evenly sprinkle TPU powder across the entire back, or apply your heat-activated adhesive according to product directions, ensuring complete coverage without clumps. Cut your backing fabric—canvas, felt, or non-slip material—slightly larger than your tufted area to allow for trimming. Preheat your heat press machine to the recommended temperature, usually 300°F for TPU applications. Place a sheet of silicon paper on the press bed to protect it, lay your tufted piece back-up on the paper, position the backing fabric over the adhesive layer, then cover everything with another sheet of silicon paper to prevent any adhesive from contacting the upper platen. Close the press firmly and hold for 15-20 seconds, applying consistent pressure across the entire surface. Open carefully, peel away the top silicon paper while the piece is still warm, and immediately place a flat weight over it as it cools for three to five minutes. Once cooled, trim excess backing flush with your tufted edges, and your piece is complete—sealed, durable, and ready for display or use with a professional finish that resists fraying and separation.

Maintenance and Storage for Longevity

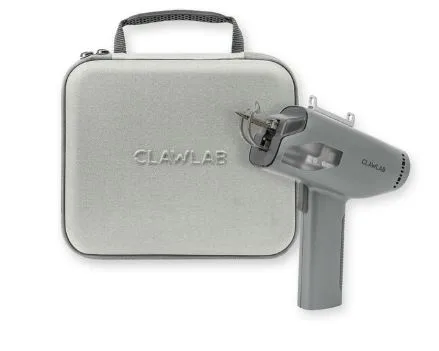

Regular maintenance extends your lightweight tufting gun’s lifespan and prevents mid-project failures that ruin hours of work. After every session, unplug the gun and remove the needle, then use a small brush or compressed air to clear lint and fiber debris from the needle channel, feed mechanism, and motor vents—accumulated buildup causes overheating and jamming. Apply one or two drops of sewing machine oil to moving parts like the needle shaft and any visible pivot points, wiping away excess to prevent attracting more dust. Inspect the needle for bends, burrs, or dullness by running your finger lightly along the tip; even slight damage causes skipped stitches and backing tears, so replace needles at the first sign of wear rather than struggling through degraded performance. Check power cords for fraying near connections and ensure all screws remain tight, as vibration loosens fasteners over time. Store your tufting gun in a protective case or padded bag away from humidity and temperature extremes, which warp plastic components and rust metal parts. Keep needles in labeled containers organized by size, and store yarn in sealed bins to prevent dust accumulation and tangling. Scissors, threaders, and tension guides deserve similar care—wipe blades clean, store small parts together, and maintain an inventory checklist so you notice missing components before starting your next project. Many manufacturers like Clawlab provide detailed maintenance guidelines specific to their tufting gun models, which can help you understand the particular care requirements for your equipment’s design and components. If your gun begins running louder, vibrating excessively, or producing inconsistent stitches despite proper threading and tension, internal gears may need professional servicing. Addressing these maintenance tasks takes fifteen minutes after each session but prevents costly replacements and ensures your lightweight tufting gun delivers reliable performance across hundreds of projects, making it a worthwhile investment in your craft practice.

Achieving Tufting Excellence Through Prevention and Practice

Mastering your lightweight tufting gun requires vigilance at every stage—from initial calibration and material selection through operational technique, finishing procedures, and ongoing maintenance. The mistakes outlined here share a common thread: they’re preventable through patience, preparation, and attention to detail. Skipping setup steps leads to mechanical failures, choosing incompatible materials produces weak results, rushing through tufting creates uneven work, and neglecting finishing transforms promising pieces into short-lived disappointments. Yet each error offers a learning opportunity that builds your expertise. By investing time in proper calibration, selecting appropriate yarn and backing, practicing controlled technique on scrap fabric, and applying professional finishing methods with tools like heat press machines and silicon paper, you transform frustration into confidence. Your lightweight tufting gun becomes an extension of your creative vision rather than a source of setbacks. The satisfaction of completing a durable, gallery-worthy textile piece—one that withstands use, cleaning, and time without unraveling—makes every careful step worthwhile. Embrace these solutions, practice deliberately, and watch your craft evolve from tentative experiments into flawless textile art that reflects both skill and passion.