Avoid Delays: Source DS200SLCCG1ACC Automation Parts Easily

The DS200SLCCG1ACC serves as a vital component in GE automation systems, functioning as a control board that ensures seamless operation of industrial processes. When this part fails, production lines can halt, resulting in costly downtime and operational disruptions. However, sourcing original GE parts presents significant challenges for maintenance teams. The discontinuation of certain product lines, limited distributor networks, and the prevalence of incompatible alternatives create obstacles that can extend repair timelines from days to weeks. Every hour of delay translates to lost productivity, missed deadlines, and frustrated stakeholders. The urgency intensifies when facilities lack adequate spare part inventories or reliable supplier relationships. This article addresses these critical sourcing challenges head-on, providing maintenance professionals and procurement teams with practical strategies to locate and secure DS200SLCCG1ACC parts quickly. By understanding where to search, how to verify authenticity, and which suppliers maintain consistent stock levels, you can minimize downtime and keep your automation systems running at peak performance.

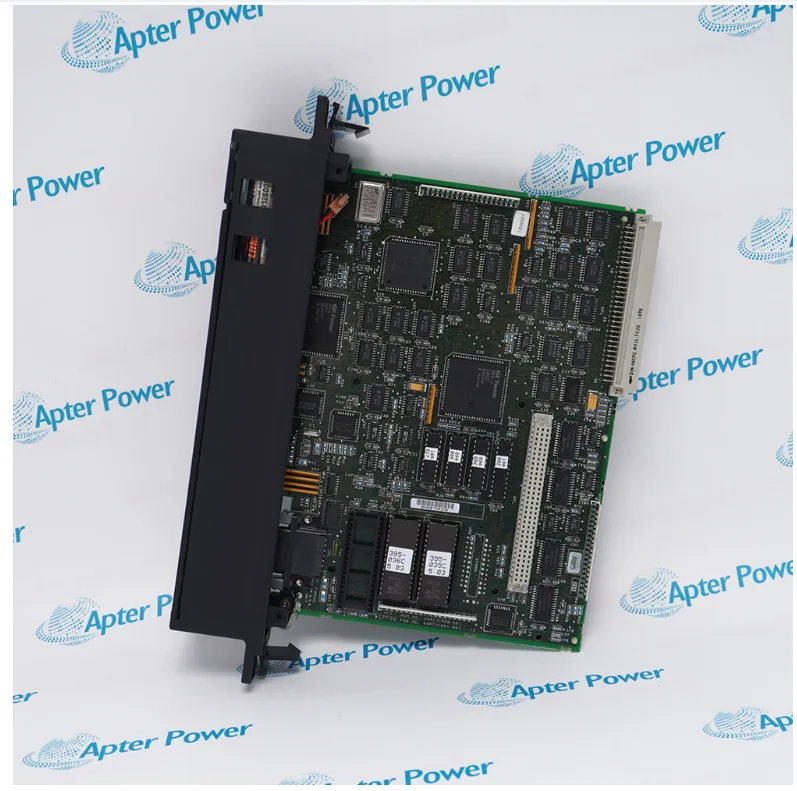

Understanding the DS200SLCCG1ACC Automation Control Part

The DS200SLCCG1ACC is a specialized control board designed for GE Mark V turbine control systems, commonly deployed in power generation facilities, oil and gas operations, and heavy industrial environments. This component manages critical functions including signal processing, logic control, and communication between system modules. Its robust design handles high-temperature environments and continuous operation cycles that characterize industrial automation applications. The board integrates with other Mark V components to maintain precise control over turbine operations, ensuring efficiency and safety standards are met consistently.

Using original GE parts rather than aftermarket alternatives protects system integrity in measurable ways. Genuine DS200SLCCG1ACC boards undergo rigorous testing protocols that verify compatibility with existing firmware versions, ensuring seamless integration without software conflicts. Original components maintain the precise electrical specifications required for accurate signal transmission, preventing the voltage irregularities and timing errors that compromise control accuracy. Warranty coverage remains intact when facilities use manufacturer-approved parts, while third-party alternatives often void service agreements and create liability concerns during audits.

Replacement becomes necessary when boards exhibit specific failure patterns. Power supply issues manifest as intermittent system resets or complete startup failures. Communication errors between modules create data transmission gaps that disrupt control sequences. Physical damage from electrical surges, environmental contamination, or component aging leads to erratic behavior that standard troubleshooting cannot resolve. Recognizing these failure signatures early allows maintenance teams to source replacements before complete system shutdowns occur, transforming planned maintenance into emergency repairs that multiply costs and extend downtime.

Challenges in Sourcing GE Automation Parts

The discontinuation of GE’s Mark V product line has created a supply chain bottleneck that affects maintenance operations worldwide. As manufacturing ceased for legacy components like the DS200SLCCG1ACC, the remaining inventory scattered across a fragmented network of distributors, surplus dealers, and repair facilities. Many authorized distributors phased out stock as demand shifted to newer platforms, leaving maintenance teams to navigate an increasingly complex sourcing landscape. This scarcity drives up lead times, with some facilities reporting waits of four to eight weeks for parts that were once available within days.

The supply gap has attracted counterfeit manufacturers and sellers offering “compatible” alternatives that appear identical but fail under operational conditions. These imitations use substandard components that cannot withstand the thermal cycling and electrical loads of industrial environments. Installation of counterfeit boards often triggers cascading failures, damaging connected modules and extending repair timelines far beyond the original issue. Visual inspection rarely reveals these differences, making authentication a critical yet challenging step in the procurement process.

Time pressure compounds these sourcing difficulties when unexpected failures occur. Production schedules cannot accommodate extended repair windows, forcing maintenance teams to accept expedited shipping costs or compromise on part verification procedures. Emergency sourcing often means paying premium prices to intermediaries who lack transparent supply chains. Without established supplier relationships or pre-vetted sources, each urgent procurement becomes a high-stakes decision balancing speed, cost, and authenticity concerns that can determine whether downtime lasts hours or weeks.

How to Check Live Stock Levels for Urgent Repairs

Real-time inventory visibility transforms urgent part searches from guesswork into targeted procurement. Industrial parts marketplaces like PLC Center, Automation24, and EU Automation maintain live databases that display current stock levels for legacy components including the DS200SLCCG1ACC. These platforms aggregate inventory from multiple suppliers, allowing you to compare availability across dozens of sources in minutes rather than making individual phone calls. Search filters enable you to narrow results by condition (new, refurbished, or surplus), location for faster shipping, and supplier ratings based on previous customer experiences. Many platforms update stock counts hourly, ensuring the availability you see reflects actual warehouse inventory rather than outdated listings.

Authenticity verification begins before purchase through several concrete checks. Request the part’s serial number and cross-reference it against GE’s database to confirm manufacturing date and original specifications. Examine supplier-provided photos for GE’s holographic labels, which counterfeiters struggle to replicate accurately. Legitimate sellers provide documentation including certificates of conformity, traceability records showing the part’s distribution history, and test reports verifying functionality. Ask suppliers directly about their quality control processes—established vendors perform incoming inspections and functional testing before listing parts. If a supplier hesitates to provide serial numbers or detailed photos, treat it as a red flag and move to alternative sources.

Stock alert systems eliminate the need for repeated manual searches when parts are temporarily unavailable. Most industrial supply platforms offer notification services that email or text you when the DS200SLCCG1ACC becomes available. Configure alerts with your maximum acceptable lead time and budget parameters to filter notifications. Some suppliers maintain waitlists that prioritize customers when new inventory arrives, giving you first access before public listings. For critical spares, establish alerts across multiple platforms simultaneously to maximize coverage. This proactive approach converts unpredictable availability into automated monitoring, allowing you to secure parts immediately when they enter the supply chain rather than discovering stock weeks after it sells out.

Reliable Sources for Hard-to-Find GE Parts

Established industrial automation suppliers with proven track records provide the most reliable access to DS200SLCCG1ACC components. Companies specializing in legacy GE systems maintain dedicated inventory channels that source directly from decommissioned facilities, authorized surplus dealers, and certified refurbishment centers. PLC Center has built a reputation for stocking hard-to-find Mark V components with full traceability documentation. Radwell International operates a global network that consolidates inventory from multiple warehouses, offering same-day shipping for in-stock items. EU Automation focuses specifically on obsolete parts, maintaining relationships with original equipment manufacturers to authenticate every component before listing. Suppliers like Apter Power also specialize in sourcing discontinued automation and industrial spare parts, often maintaining inventory of legacy control system components. These specialized suppliers understand the urgency of industrial repairs and structure their operations around rapid fulfillment rather than mass-market retail models.

Evaluating supplier reliability requires examining specific performance indicators beyond price comparisons. Check how long the company has operated in the industrial automation sector—vendors with ten or more years demonstrate stability and industry knowledge. Review their return policies and warranty terms; reputable suppliers offer minimum 18-month warranties on refurbished parts and hassle-free returns if components fail compatibility checks. Investigate their quality control processes by asking whether they perform functional testing on used parts or simply resell untested surplus inventory. Examine customer reviews on independent platforms like Trustpilot or industry forums, focusing on comments about part authenticity, shipping speed, and post-sale support. Request references from facilities similar to yours, particularly those operating the same Mark V systems.

Building relationships with two or three vetted suppliers creates procurement flexibility that pays dividends during emergencies. Regular communication keeps you informed about incoming inventory before public listings appear. Preferred customer status often unlocks access to reserved stock, priority processing during high-demand periods, and negotiated pricing for bulk purchases. Share your facility’s parts list with suppliers so they can proactively notify you when critical components become available. Schedule quarterly reviews to assess lead times, quality consistency, and service levels, adjusting your supplier mix based on performance trends. These partnerships transform transactional part searches into strategic sourcing arrangements that reduce downtime risk and eliminate the scramble of vetting unknown vendors during crisis situations.

Step-by-Step Guide to Ordering DS200SLCCG1ACC

Compatibility verification prevents costly mistakes before placing orders. Start by documenting your system’s complete model information, including the Mark V control system version, firmware revision, and existing board serial numbers. Cross-reference the DS200SLCCG1ACC part number against your system’s bill of materials or technical documentation to confirm it matches your configuration. Contact the supplier with your system details and ask them to verify compatibility based on their technical records—reputable vendors maintain compatibility databases and can confirm fitment within hours. If documentation is unavailable, photograph your existing board’s label showing all part numbers and revision codes, then share these images with suppliers for visual confirmation. This verification step takes fifteen minutes but eliminates the risk of receiving correct part numbers that won’t integrate with your specific system version.

Effective order placement requires clear communication of your urgency level and delivery requirements. Specify whether you need new, certified refurbished, or tested surplus condition, as availability and lead times vary significantly between categories. Provide your facility’s complete shipping address with dock hours and any special receiving instructions to prevent delivery delays. Request order confirmation that includes the part’s serial number, condition grade, warranty terms, and estimated ship date. For urgent repairs, ask about cut-off times for same-day processing—many suppliers ship orders placed before 3 PM within 24 hours. Clarify payment terms upfront, as some vendors require prepayment for first-time customers while established accounts may access net-30 terms that accelerate processing.

Expedited shipping becomes cost-effective when downtime expenses exceed premium freight charges. Overnight delivery typically adds $75-150 to standard ground shipping but reduces transit from five days to one, potentially saving thousands in lost production. Some suppliers offer Saturday delivery for critical situations, ensuring weekend repairs proceed without waiting until Monday. For international shipments, work with suppliers experienced in customs documentation to avoid clearance delays—provide your facility’s import licenses and tax identification numbers at order placement. Request tracking numbers immediately upon shipment and monitor progress actively. When parts arrive, inspect packaging for damage before signing delivery receipts and verify serial numbers match order confirmations, documenting any discrepancies immediately to expedite replacements if necessary.

Strategic Sourcing for Minimal Downtime

Sourcing the DS200SLCCG1ACC requires a strategic approach that combines real-time inventory monitoring, supplier verification, and proactive relationship building. By leveraging specialized industrial automation platforms that display live stock levels, you eliminate wasted time contacting vendors with outdated listings. Authenticating parts through serial number verification, documentation review, and supplier quality control assessments protects your systems from counterfeit components that cause cascading failures. Establishing relationships with two or three vetted suppliers creates procurement flexibility that transforms emergency situations into manageable processes with predictable timelines. The key to minimizing downtime lies in preparation rather than reaction—configure stock alerts for critical components before failures occur, maintain updated system documentation that streamlines compatibility verification, and negotiate preferred customer arrangements that unlock priority access during high-demand periods. Consider conducting an annual audit of your spare parts inventory, identifying single-point-of-failure components like the DS200SLCCG1ACC that warrant backup stock. For facilities operating legacy GE Mark V systems, proactive sourcing isn’t just good practice—it’s essential insurance against the production losses and repair costs that multiply when critical parts become unavailable at the moment you need them most.