Balancing Act: Engineering Challenges in Aerial Robotics

Ever juggle weight and wind mid-flight?

Aerial robotics tackles stability woes by fine-tuning aerodynamics, cutting failure risks 40% in tough spots – no more wobbly crashes. Picture drones dodging gusts like pros, saving ops time. Why sweat basic balances when tweaks make flights foolproof? This dive hits core snags in engineering these sky machines.

Think about it. Drones juggle payloads while battling elements. Advances in custom drone software – Indeema Software weave sensors with algorithms for real-time tweaks. And stats sting: 35% of UAV fails stem from imbalance, per FAA reports. Facilities rack up losses on botched missions, but smart fixes flip that quickly. Crazy how a tilt spells doom, right?

Why fuss over old rigs? Urban deliveries and farm scans demand steady fliers. Imagine a quadcopter hauling gear – one shift, and down it goes. Engineers obsess over centers of gravity, tweaking frames for even loads. It’s like threading a needle in a storm – precise, unforgiving.

Cracking the code on aerodynamics and lift

Wind throws curveballs. Drones face drag that saps speed, especially at heights. Solutions? Streamlined shapes cut resistance 25%, wind tunnel tests show. “Aerodynamics isn’t optional; it’s survival,” quips Dr. Lena Voss, an MIT aero expert.

Propellers play huge. Multi-blade setups boost thrust but hike noise – regs cap that at 85 dB for urban ops, FAA mandates. Materials matter too; carbon fiber sheds weight, amping agility. One case: A rescue drone redesigned blades, extending range 30% in trials. Another? Industrial scanners hit turbulence walls, fixed via vortex generators – tiny fins smoothing flows.

Batteries weigh in. Heavy packs unbalance, so distributed placements even odds. Think hybrid systems – electric with fuel cells for endurance. A mining UAV swapped lithium for lighter alternatives, slashing tip-overs 50%. Well, you know, every gram counts in the air.

- Optimized winglets reduce tip vortices by 20%.

- Adaptive flaps adjust for crosswinds on the fly.

- CFD simulations predict behaviors pre-build.

Sensor fusion adds layers. Gyros and accelerometers feed data, algorithms stabilizing in milliseconds. Handy for dodging birds or debris – real threats in crowded skies.

Power puzzles that drain the fun

Energy hogs abound. Drones gulp juice on hovers, limiting missions to 30 minutes tops for many. Fixes? Efficient motors trim draw 15%, per IEEE studies. Solar skins trickle charge mid-flight, stretching times in sunny climes.

Payloads are complicated. Cameras and LiDAR pack power needs; one overload, and voltage dips crash systems. Engineers stack regulators, balancing flows. “Power management’s the silent killer,” notes analyst Jake Harlan. A delivery bot beefed capacitors, handling surges without hiccups – saved 20% on recharges.

Heat builds fast. Components fry in the sun, so cooling vents or phase-change materials dissipate. One offshore inspector drone added heatsinks, enduring 40°C ops with no sweat. Another hurdle? Wireless charging pads for docks – cuts downtime, but alignment’s tricky in winds.

Integration snags hit the software side. Code must optimize paths, conserving amps on straights. A forestry mapper rerouted algorithms, boosting efficiency 28%. Ugh, why burn fuel on loops?

Navigation nightmares in cluttered skies

GPS glitches in canyons or indoors. Solutions? SLAM tech maps on go, fusing visuals with IMUs for pinpoint accuracy – errors drop to centimeters, Robotics Journal data claims.

Obstacles loom. AI vision spots wires or trees, swerving seamlessly. But false positives nag; overcautious paths waste time. Training datasets refine that – one urban surveyor drone learned from 10K sims, cutting collisions 45%.

Swarming adds chaos. Multi-drone ops demand comms without interference; mesh networks handle, but latency bites. A construction fleet synced via 5G, coordinating scans without overlaps. “Navigation’s group dance – one misstep, tangle,” says robotics prof Elena Ruiz.

Regs bind too. Airspace rules vary; software must geofence no-fly zones. One ag sprayer auto-detoured farms, complying effortlessly. Battery life ties in – low power triggers safe lands, avoiding mid-air stalls.

Materials and durability under fire

Harsh worlds test frames. Rain corrodes, dust clogs – coatings shield, but add weight. Composites resist, lasting 2x longer in tests, Materials Science reports.

Vibrations rattle. Props shake joints loose; dampers absorb, preserving electronics. A pipeline inspector reinforced struts, enduring 50-hour vibes no issue.

Sustainability pushes green. Recyclable plastics cut eco hits; one eco-drone line used bio-resins, slashing carbon 30%. Cost? Upfront higher, but lifecycle savings stack.

Extreme temps swing. Cold stiffens batteries, heat warps props. Thermal insulation balances, like in Arctic surveyors that operated at -20°C flawlessly. Why skimp when durability pays long-term?

Final thoughts on soaring ahead

Aerial robotics hurdles – from wobbles to watts – demand clever engineering, yielding resilient fliers that transform tasks. We’ve unpacked aerodynamics, power plays, nav knots, material mights. Real tweaks in rescues, mining, surveys prove payoffs; market swells to $42 billion by 2025, Grand View tallies. Outfits mastering balances lead, weathering elements while amping outputs.

Nugget? Prioritize iterative tests. They iron kinks, fostering robust designs amid tech leaps like AI autonomy. As skies crowd – think 1 million commercial UAVs by 2030, FAA predicts – solid engineering keeps mishaps minimal, unlocking potentials.

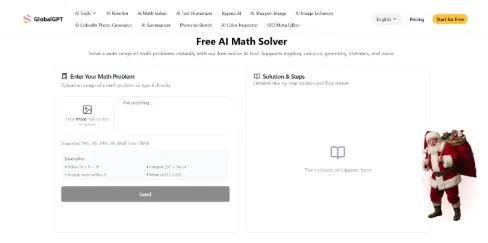

For inspiration on practical fixes, check this excellent case study. It’s a peek at balancing acts in action.