Bently Nevada 1900/65a Parts: Refurbished Options & Warranty Guide

In the demanding world of industrial automation, Bently Nevada 1900/65a parts serve as essential components for vibration monitoring and machinery protection systems. These critical elements keep production lines running smoothly and prevent costly equipment failures across manufacturing facilities, power generation plants, and processing operations worldwide. However, maintenance managers frequently encounter significant challenges when sourcing reliable spare parts, from extended lead times and high costs to concerns about component authenticity and compatibility. Refurbished options have emerged as a practical solution that addresses these pain points while delivering substantial cost savings without compromising performance. Understanding warranty coverage and selecting trustworthy suppliers becomes paramount when integrating these components into existing systems. This guide explores how refurbished Bently Nevada parts can support your maintenance strategy, examining quality standards, warranty considerations, and sourcing best practices that help you maintain operational continuity while managing budget constraints effectively.

Understanding Bently Nevada 1900/65a Parts

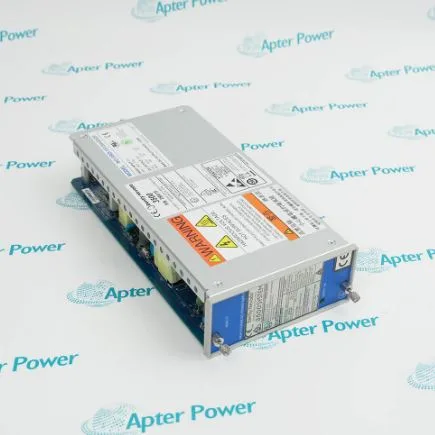

The Bently Nevada 1900/65a General Purpose Equipment Monitor represents a sophisticated vibration monitoring solution designed for continuous machinery protection in industrial environments. This rack-mounted system monitors critical rotating equipment such as turbines, compressors, pumps, and motors by processing signals from proximity probes and accelerometers. The 1900/65a accepts up to four channels of vibration data, providing real-time analysis of shaft position, vibration amplitude, and bearing condition. Its modular architecture includes power supply modules, monitor cards, relay output modules, and communication interfaces that integrate seamlessly with distributed control systems and SCADA networks.

Key specifications include configurable alarm setpoints, 4-20mA output signals for continuous monitoring, and relay contacts for shutdown protection. The system operates reliably in harsh conditions with temperature ranges from -30°C to +65°C and can withstand significant electromagnetic interference without signal degradation. These capabilities make it indispensable for facilities requiring 24/7 uptime and predictive maintenance capabilities.

Common issues necessitating part replacement include power supply failures due to voltage fluctuations, monitor card degradation from prolonged exposure to industrial environments, and relay module wear from frequent switching cycles. Communication interface failures often occur when systems require protocol upgrades or network integration changes. Environmental factors such as dust accumulation, temperature cycling, and humidity can accelerate component aging, while obsolescence challenges emerge as facilities extend equipment lifecycles beyond original manufacturer support timelines. Recognizing these failure patterns helps maintenance teams plan proactive replacement strategies and maintain adequate spare part inventories.

Benefits of Refurbished Bently Nevada Parts

Refurbished Bently Nevada 1900/65a parts typically deliver cost savings ranging from 40% to 70% compared to new factory components, providing immediate budget relief for maintenance departments facing capital constraints. These savings accumulate significantly across multi-site operations or when maintaining large installed bases of monitoring equipment. Beyond financial advantages, refurbished components support sustainability initiatives by extending product lifecycles and reducing electronic waste. Manufacturing new industrial electronics requires substantial energy consumption and raw materials, while refurbishment diverts functional components from landfills and minimizes the carbon footprint associated with production and shipping.

Professional refurbishment processes restore parts to original equipment manufacturer specifications through comprehensive testing protocols. Reputable refurbishers disassemble components completely, inspect for wear or damage, replace degraded elements, clean and recalibrate circuits, then subject units to burn-in testing that simulates operational conditions. This rigorous approach often identifies latent defects that might escape initial factory testing, potentially delivering greater reliability than some new stock items. Refurbished parts undergo functional verification across their full operating range, including alarm setpoint accuracy, output signal linearity, and communication protocol compliance.

Quality refurbished components meet the same performance standards as new parts when sourced from certified providers who maintain ISO-compliant facilities and employ trained technicians familiar with Bently Nevada systems. These parts integrate seamlessly with existing installations, maintaining compatibility with legacy configurations while supporting current system requirements. The refurbishment industry has matured considerably, with established quality frameworks ensuring that properly refurbished automation components perform reliably throughout their service life, backed by warranties that demonstrate supplier confidence in their restoration processes.

Sourcing Reliable Bently Nevada Spare Parts

Identifying reputable suppliers begins with verifying their industry certifications and track record in industrial automation components. Look for distributors holding ISO 9001 quality management certifications and memberships in recognized trade organizations such as the Control System Integrators Association. Established suppliers typically maintain transparent business practices, providing detailed company histories, customer references, and facility information. Check for specialized expertise in Bently Nevada systems specifically rather than general electronics resellers, as specialized knowledge ensures proper handling and testing protocols.

Quality assurance processes should include comprehensive incoming inspection, functional testing across operational parameters, calibration verification against OEM specifications, and documented traceability for each component. Request detailed information about refurbishment procedures, including what testing equipment suppliers use and whether they maintain environmental test chambers for temperature cycling verification. Reputable providers willingly share test reports, certification documents, and photographic evidence of their refurbishment facilities. They should offer pre-shipment testing data specific to your purchased unit, demonstrating alarm functionality, output accuracy, and communication protocol performance.

Verification methods for part authenticity include examining serial numbers against manufacturer databases, inspecting physical markings for consistency with genuine components, and requesting certificates of conformity. Authentic Bently Nevada parts feature specific labeling conventions, connector types, and board layouts that differ from counterfeit versions. When possible, cross-reference part numbers with official documentation and verify that packaging matches OEM standards.

Lead time considerations vary significantly between suppliers, with established distributors maintaining inventory of common modules for immediate shipment while rare components may require refurbishment upon order. Specialized suppliers in the automation and industrial spare parts sector, such as Apter Power, often maintain extensive inventories of refurbished Bently Nevada components to support rapid deployment needs. Plan maintenance activities around typical lead times of two to four weeks for standard refurbished parts, though expedited services often reduce this to days for critical situations. Building relationships with multiple qualified suppliers provides backup options when urgent needs arise, ensuring your maintenance schedule remains flexible without compromising component quality or authenticity verification standards.

Warranty Options for Purchased Parts

Standard warranty coverage for refurbished Bently Nevada 1900/65a parts typically ranges from six months to two years, depending on the supplier’s confidence in their refurbishment processes and component condition. Most reputable providers offer a minimum one-year warranty covering defects in materials and workmanship, protecting against failures resulting from the refurbishment process itself. These warranties generally include replacement or repair at no additional cost, with suppliers covering return shipping for defective units. Standard coverage excludes damage from improper installation, environmental factors beyond specified operating conditions, or modifications made after purchase. Understanding exactly what situations trigger warranty protection helps maintenance teams document installation procedures and operating conditions appropriately.

Extended warranty options provide additional protection beyond standard coverage periods, typically extending coverage to three or five years for an additional fee ranging from 15% to 30% of the component cost. These programs prove particularly valuable for critical applications where unexpected failures create significant production losses or safety concerns. Extended warranties often include priority technical support, expedited replacement services, and sometimes preventive maintenance consultations. Evaluate whether extended coverage aligns with your equipment criticality assessment and replacement budget cycles, particularly for components in harsh operating environments or applications with limited redundancy.

Warranty terms specify critical conditions including proper storage before installation, adherence to manufacturer installation guidelines, and operation within rated parameters. Most warranties require prompt failure notification, typically within 48 hours of discovering defects, and return of failed components for analysis. Review exclusions carefully, as warranties typically void if unauthorized personnel attempt repairs or if components show evidence of physical damage, liquid exposure, or electrical overstress. Some suppliers impose restocking fees for returns outside warranty periods or require original packaging for warranty claims.

The warranty claim process begins with contacting your supplier’s technical support team to describe the failure symptoms and provide installation details. Suppliers typically request diagnostic information including error codes, operating conditions at failure, and photographs of the installation. Upon approval, they issue a return authorization number and shipping instructions. Document the failure thoroughly with timestamps, system logs, and environmental data to expedite claim processing. Reputable suppliers process warranty claims within five to ten business days after receiving the returned component, shipping replacements via expedited methods to minimize downtime. Establish clear internal procedures for initiating warranty claims promptly, as delays in reporting failures may complicate coverage determinations and extend your equipment downtime unnecessarily.

Implementation and Maintenance Tips

Proper installation of refurbished Bently Nevada 1900/65a components begins with verifying compatibility between the replacement part and your existing system configuration. Before removing the failed component, document all cable connections with photographs and labels, noting wire positions, terminal assignments, and configuration switch settings. Power down the entire monitoring rack following lockout-tagout procedures to prevent electrical hazards. Handle circuit boards by their edges to avoid electrostatic discharge damage, using grounded wrist straps in environments prone to static buildup. Insert modules firmly into their designated slots, ensuring connector pins align correctly without forcing connections. After installation, verify all cable terminations match original configurations, then restore power gradually while monitoring for error indicators. Perform functional testing by simulating sensor inputs and confirming alarm setpoints trigger appropriately before returning the system to production service.

Establishing preventive maintenance schedules significantly extends component lifespan and reduces unexpected failures. Quarterly inspections should include visual examination for dust accumulation, corrosion on connectors, and signs of overheating such as discolored circuit boards. Clean ventilation openings and cooling fans using filtered compressed air to maintain proper thermal management. Semi-annual calibration verification ensures output signals remain within tolerance, comparing 4-20mA outputs against precision measurement equipment. Annual comprehensive testing should evaluate all alarm functions, communication protocols, and relay operations under simulated fault conditions. Maintain detailed maintenance logs documenting inspection findings, calibration results, and any corrective actions taken.

When troubleshooting issues, begin with systematic diagnostic approaches rather than immediate component replacement. Intermittent alarms often indicate loose connections or sensor cable problems rather than monitor failures. Communication errors frequently stem from network configuration changes or protocol mismatches. Test power supply voltages at multiple points to isolate electrical issues before replacing modules. Deciding between repair and replacement depends on component age, failure frequency, and availability of repair services. Replace components showing recurring failures within short intervals or those approaching ten years of service life. Consider repair for isolated incidents on newer refurbished parts still under warranty, as suppliers often provide technical support to resolve issues without full replacement, minimizing downtime and preserving your maintenance budget.

Maximizing Value Through Strategic Sourcing

Refurbished Bently Nevada 1900/65a parts deliver compelling advantages for maintenance managers navigating budget pressures while maintaining equipment reliability. The substantial cost savings of 40% to 70% compared to new components free capital for other critical projects without sacrificing performance when sourced from certified suppliers. These professionally restored parts meet OEM specifications through rigorous testing protocols, supporting both operational continuity and sustainability objectives by reducing electronic waste. Proper sourcing requires diligence in verifying supplier credentials, examining quality assurance processes, and confirming part authenticity through documented traceability. Understanding warranty coverage protects your investment, with standard one-year warranties providing baseline protection and extended options offering additional security for critical applications. Successful implementation depends on following proper installation procedures, establishing preventive maintenance schedules, and maintaining detailed documentation for warranty claims. For maintenance managers seeking reliable spare parts that balance cost-effectiveness with performance requirements, refurbished Bently Nevada components represent a proven solution. Begin by identifying qualified suppliers with demonstrated expertise in vibration monitoring systems, request detailed refurbishment documentation, and establish relationships that support your long-term maintenance strategy. Taking these steps ensures your facility maintains the machinery protection capabilities essential for safe, efficient operations while optimizing spare parts expenditures.