Chocolate Melter vs Tempering Machine: Key Differences

What is the Difference Between Chocolate Melter and Tempering Machine?

Working with chocolate requires precision, patience, and the right equipment. Whether you’re a home baker experimenting with chocolate-dipped strawberries or a professional chocolatier crafting artisan bonbons, understanding the difference between chocolate melter and tempering machine is crucial for achieving the results you desire. While both pieces of equipment work with melted chocolate, they serve fundamentally different purposes and produce vastly different outcomes. A chocolate melter simply liquefies chocolate for immediate use, while a chocolate tempering machine performs the precise temperature manipulation necessary to create stable, glossy, professional-quality chocolate with that signature snap.

Understanding Chocolate Melters

A chocolate melter is designed with simplicity in mind, focusing on one primary task: transforming solid chocolate into a smooth, workable liquid state.

What is a Chocolate Melter?

A chocolate melter is a heating appliance that maintains chocolate in a liquid state at a consistent temperature, typically between 40-50°C (104-122°F). These machines use gentle, indirect heat—often through a water bath or heating element—to prevent scorching and keep chocolate flowing smoothly. The basic design includes a container or basin for holding chocolate, a heating source, and simple temperature controls. Unlike more sophisticated equipment, chocolate melters don’t cycle through different temperature stages; they simply hold chocolate at one steady melting point.

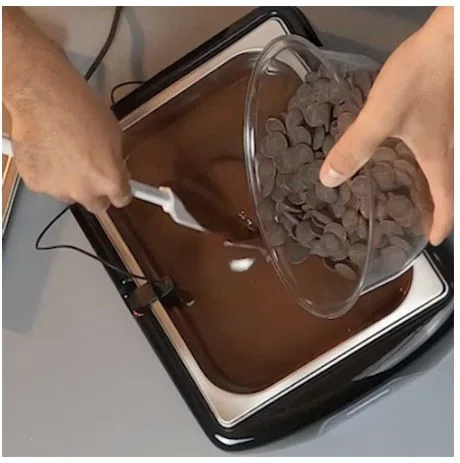

The operation is straightforward and user-friendly, making these machines popular for casual chocolate work. You add solid chocolate to the basin, turn on the heat, wait for it to melt completely, and maintain that temperature throughout your project. Some models feature multiple compartments, allowing you to work with different chocolate varieties or colors simultaneously without cross-contamination.

Best Uses for Chocolate Melters

Chocolate melters excel in applications where tempering chocolate isn’t required or where you’re working with compound chocolate (chocolate-flavored coatings that contain vegetable fats instead of cocoa butter). They’re ideal for chocolate fountains at events, creating simple chocolate drizzles over desserts, preparing fondue, or dipping fruits and cookies for casual gatherings. Home bakers find them perfect for melting chocolate chips for brownies, creating ganache, or making simple chocolate decorations that will be consumed quickly.

These machines work beautifully with compound coatings, candy melts, and chocolate products that don’t require the precise crystal structure of tempered chocolate. If you’re running a small café offering chocolate-dipped treats or hosting dessert parties, a melter provides convenient, consistent results without the learning curve of professional chocolate tempering. However, the chocolate produced won’t have the glossy finish, firm snap, or shelf stability of properly tempered chocolate—it may develop bloom (that whitish coating), feel softer at room temperature, and melt more easily in your hands.

Understanding Chocolate Tempering Machines

Chocolate tempering machines represent a significant step up in sophistication, designed specifically to manipulate chocolate’s molecular structure for professional results.

What is a Chocolate Tempering Machine and Why Tempering Matters

A chocolate tempering machine is specialized equipment that guides chocolate through a precise temperature sequence to encourage stable cocoa butter crystallization. This process—called tempering—is essential when working with real chocolate (couverture) containing cocoa butter. The science behind tempering chocolate involves understanding that cocoa butter can crystallize in six different forms (labeled I through VI), but only Form V produces the desirable qualities chocolatiers seek: a smooth, glossy surface, firm texture at room temperature, pleasant snap when broken, and resistance to bloom.

Without proper tempering, chocolate may look dull, feel soft or greasy, melt too quickly, or develop unsightly white streaks and spots over time. Professional chocolatiers, pastry chefs, and serious chocolate enthusiasts rely on chocolate tempering machines to consistently achieve these crystal structures without the guesswork and physical labor of manual tempering methods. The investment in a tempering machine pays dividends in product quality, consistency, and time savings for anyone working with chocolate regularly.

How Tempering Machines Work

A chocolate tempering machine automates the three-stage temperature process that creates stable chocolate. First, the machine heats chocolate to approximately 45-50°C (113-122°F) to melt all existing cocoa butter crystals completely, erasing any previous crystal memory. Next, it carefully cools the chocolate to around 27-28°C (80-82°F) for dark chocolate, encouraging the formation of stable Form V crystals while preventing unstable crystal types from dominating. Finally, it gently reheats to the working temperature of 31-32°C (88-90°F) for dark chocolate, melting any unstable crystals while preserving the desirable Form V crystals.

Throughout this process, many chocolate tempering machines feature continuous agitation or stirring mechanisms that distribute heat evenly and prevent localized temperature variations. Advanced models include digital controls with preset programs for different chocolate types (dark, milk, and white), automatic temperature adjustments, and holding functions that maintain properly tempered chocolate at working temperature for extended periods. This automation eliminates the constant monitoring, thermometer checking, and manual stirring required with traditional tempering methods.

Key Differences Between Chocolate Melters and Tempering Machines

Understanding the core distinctions helps you choose the right equipment for your specific chocolate applications.

Temperature Control Capabilities

The most fundamental difference between chocolate melter and tempering machine lies in temperature control sophistication. A chocolate melter maintains a single, constant temperature—you set it, and it holds chocolate in that liquid state indefinitely. This simple approach works for melting but cannot create the temperature curves necessary for proper chocolate crystallization. In contrast, a chocolate tempering machine features precision temperature programming that cycles through the heating, cooling, and reheating stages automatically, often with accuracy within 0.5°C.

This precision matters immensely when working with real chocolate. Just a few degrees’ difference determines whether you achieve stable Form V crystals or end up with unstable formations that compromise your final product. While you can manually temper chocolate using a melter and external temperature manipulation, it requires significant skill, constant attention, and yields inconsistent results compared to dedicated tempering equipment.

Impact on Final Product Quality

The equipment you choose directly influences your chocolate’s appearance, texture, and stability. Chocolate from a melter, when it solidifies, often appears dull or streaky with an inconsistent surface. It may feel slightly soft or tacky at room temperature, lack that satisfying snap when you break it, and leave residue on your fingers when handled. Within days or weeks, you’ll likely notice bloom developing—those white or grayish streaks and spots caused by unstable fat or sugar crystals migrating to the surface.

Properly tempered chocolate from a chocolate tempering machine showcases entirely different characteristics. The surface appears glossy and uniform, with professional-looking sheen that catches light beautifully. The texture feels firm and smooth, breaking cleanly with an audible snap rather than bending or crumbling. It resists fingerprints, releases cleanly from molds, and maintains stability at room temperature for months without developing bloom. For chocolatiers creating products meant for display, sale, or gifting, these quality differences make tempering machines indispensable tools.

Price and Investment Considerations

Budget naturally plays a role in equipment decisions. Basic chocolate melters start around $30-$100 for small home models, with commercial-grade units ranging from $200-$800 depending on capacity and features. These represent relatively modest investments, making them accessible entry points for hobbyists and small operations. Chocolate tempering machines, reflecting their sophisticated technology, command higher prices—compact home models begin around $200-$500, while professional-grade equipment ranges from $1,000 to $10,000+ for high-volume industrial machines.

However, price comparisons should consider the value proposition for your specific needs. If you primarily work with compound chocolate, make occasional chocolate-dipped treats, or operate on a tight budget, a melter delivers excellent value. But if you’re producing molded chocolates, bonbons, chocolate bars, or any products requiring professional appearance and shelf life, investing in a tempering machine becomes not just worthwhile but essential. The consistency, quality, and time savings quickly justify the initial expense for serious chocolate work. Zucchero Canada offers a range of chocolate tempering machines suitable for both small artisan operations and larger commercial production.

When to Use a Chocolate Melter

Chocolate melters shine in specific scenarios where simplicity and convenience outweigh the need for tempered chocolate properties.

Home bakers working on casual projects find melters perfect for their needs. When you’re making chocolate-dipped pretzels for a family gathering, drizzling chocolate over ice cream sundaes, preparing chocolate fondue for a party, or melting chocolate for cookie recipes, a basic melter provides everything necessary. The chocolate doesn’t need to maintain stability for weeks or resist fingerprints—it just needs to be smooth, melted, and ready to use.

Melters also excel when working with compound chocolate or candy melts—products specifically formulated to set without tempering. These chocolate alternatives contain vegetable oils instead of cocoa butter, eliminating crystallization concerns. They’ll set firm and glossy straight from a melter without any temperature manipulation, making them ideal for quick decorating projects, cake pops, and casual confections. Small cafés, school kitchens, and catering operations often find melters sufficient for their chocolate needs, especially when producing items consumed immediately rather than stored long-term. Budget-conscious operations just starting with chocolate work can begin with a melter and upgrade to tempering equipment as their skills and production demands grow.

When to Use a Chocolate Tempering Machine

Professional chocolate applications demand the precision and consistency that only chocolate tempering machines provide.

If you’re crafting bonbons with delicate fillings, molding chocolate bars for retail sale, creating chocolate decorations for fine dining presentations, or producing any chocolate products meant for display, gifting, or commercial sale, a tempering machine becomes non-negotiable. The professional appearance, structural integrity, and shelf stability of tempered chocolate simply cannot be reliably achieved through melters alone. Chocolatiers building their brand reputation need the consistent quality that tempering equipment delivers—every truffle, every molded piece, every chocolate decoration meets the same high standard.

Working with premium couverture chocolate—the high-quality chocolate preferred by professionals for its superior flavor and cocoa butter content—requires proper tempering to unlock its full potential. These expensive chocolates deserve equipment that respects their quality and maximizes their performance. Even serious home enthusiasts who’ve moved beyond basic chocolate work and want to create impressive homemade chocolates for special occasions find tempering machines transform their results. The learning curve for manual tempering can be frustrating, with countless batches wasted on imperfect crystallization. A quality tempering machine eliminates this trial-and-error, producing reliably excellent chocolate from your first use.

Can You Use a Chocolate Melter for Tempering?

This common question deserves a nuanced answer that addresses both technical possibility and practical reality.

Technically, you can attempt to temper chocolate using just a melter, but it requires manual intervention, external cooling methods, and considerable skill. The process involves melting chocolate in the melter, then removing portions to cool on a marble slab or through seeding methods (adding already-tempered chocolate to melted chocolate), constantly monitoring temperatures with a reliable thermometer, and stirring vigorously to distribute the proper crystal formation. Some experienced chocolatiers successfully use this approach, particularly when working with small quantities.

However, this manual process presents significant challenges. Maintaining precise temperature control without automated cycling proves difficult and inconsistent. You’ll spend considerable time hovering over the chocolate, testing temperatures, and adjusting constantly—time that could be spent on creative work rather than technical management. Results vary batch to batch depending on ambient room temperature, your stirring technique, and how accurately you hit those critical temperature points. For anyone working with chocolate regularly or producing products for sale, the frustration, wasted chocolate, and inconsistent outcomes make dedicated chocolate tempering machines worth every penny. The question isn’t whether you can use a melter for tempering—it’s whether you should, and for most serious applications, the answer is no.

Choosing the Right Equipment for Your Needs

Making the right equipment investment requires honest assessment of your chocolate work’s scope and goals.

Start by evaluating your typical projects. Are you making occasional chocolate-dipped treats for family enjoyment, or are you building a chocolate business requiring consistent professional results? Consider your production volume—a few dozen pieces monthly versus hundreds weekly demands different equipment levels. Think about the chocolate types you prefer working with: if compound chocolate and candy melts dominate your projects, a chocolate melter suffices beautifully. If you’re passionate about working with fine couverture chocolate and want to master professional techniques, invest in a tempering machine from the start.

Budget naturally influences decisions, but consider the total cost of ownership. A chocolate melter represents lower initial investment but may limit your growth and product quality. A chocolate tempering machine costs more upfront but eliminates wasted chocolate from failed tempering attempts, saves countless hours of manual temperature management, and enables you to charge premium prices for professional-quality products. Many chocolatiers recommend beginners serious about chocolate work skip the melter entirely and invest in an entry-level tempering machine, viewing it as an investment in their education and future production quality rather than an expense.

Your skill level and willingness to learn also matter. If chocolate work represents a casual hobby you enjoy occasionally, the complexity of tempering equipment might feel overwhelming, and a simple melter better suits your needs. But if you’re committed to developing chocolate artistry skills and producing impressive creations, a tempering machine accelerates your learning by removing technical variables and letting you focus on creativity and technique refinement.

Conclusion

The difference between chocolate melter and tempering machine ultimately boils down to purpose and precision. Chocolate melters provide convenient, affordable solutions for simple melting tasks, casual chocolate work, and applications using compound chocolate or products consumed immediately. They serve home bakers, casual enthusiasts, and operations where chocolate quality takes a backseat to convenience and cost. Chocolate tempering machines, in contrast, deliver the temperature precision necessary for professional-quality chocolate with glossy finish, firm snap, and long-term stability—essential tools for chocolatiers, pastry professionals, and anyone serious about chocolate craft.

Your choice should align with your specific needs, production volume, and quality expectations. If you’re ready to elevate your chocolate work with professional tempering equipment, Zucchero Canada offers expert guidance and high-quality chocolate tempering machines designed for both artisan chocolatiers and commercial operations. Invest in the right equipment for your chocolate journey, and watch your creations transform from homemade treats to professional-grade confections.

References

Beckett, S. T. (2018). The science of chocolate (3rd ed.). Royal Society of Chemistry.

Greweling, P. (2012). Chocolates and confections: Formula, theory, and technique for the artisan confectioner (2nd ed.). John Wiley & Sons.

Talbot, G. (2009). Science and technology of enrobed and filled chocolate, confectionery and bakery products. Woodhead Publishing.

Afoakwa, E. O. (2016). Chocolate science and technology (2nd ed.). Wiley-Blackwell.

McGee, H. (2004). On food and cooking: The science and lore of the kitchen. Scribner.