Choosing the Right Diesel Engine: A Guide for Heavy Truck Operators

Heavy-duty trucks are essential to the logistics and transportation industry, enabling goods to move efficiently across cities, states, and even international borders. The engine is the core component that determines performance, reliability, and operational lifespan. For many fleet operators, sourcing high-quality used diesel engines provides a cost-effective solution without sacrificing durability or efficiency. Understanding the different engine types, how to evaluate them, and sourcing from trusted suppliers is critical for maintaining a reliable and productive fleet.

Understanding Diesel Engine Types

Diesel engines vary in torque, power output, and design, and choosing the right model depends on fleet requirements. Operators typically rely on engines from trusted manufacturers such as Cummins, Detroit Diesel, CAT, and Paccar. These brands are recognized for their durability, consistent performance, and longevity.

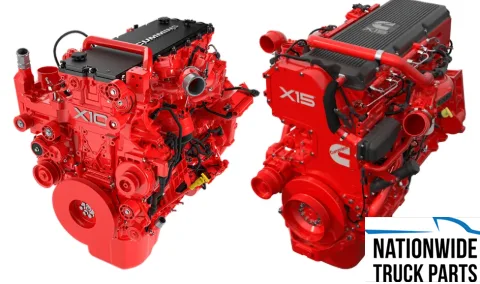

- Cummins X15: Designed for both long-haul and vocational applications, the X15 provides high torque and advanced fuel efficiency. Its engineering emphasizes reliability under heavy loads and extended routes, making it ideal for trucks that cover long distances daily. Understanding its performance characteristics helps operators maintain consistent engine function over time.

- Detroit DD15: Valued for its balance of power and fuel efficiency, the DD15 is widely used in regional and local transport. Advanced fuel systems and emission control technology allow this engine to maintain performance while meeting environmental standards.

- CAT C15: Known for its robust construction, the CAT C15 excels in high-stress environments such as construction, logging, and heavy-haul operations. Consistent maintenance and proper lubrication are key to ensuring it performs reliably under demanding conditions.

- Paccar MX-13: This engine emphasizes durability, reduced maintenance, and fuel efficiency, making it suitable for regional and long-distance hauls. Its longevity reduces operational interruptions, contributing to lower downtime and enhanced productivity.

Understanding specifications such as horsepower, torque output, and fuel system configuration is essential when selecting an engine. Operators should consider typical loads, route length, and operating conditions to determine the most suitable engine for their fleet.

Importance of Quality and Testing

Quality and reliability are crucial when sourcing used diesel engines. Selecting engines without thorough inspection can lead to unexpected failures and costly downtime. Operators should prioritize suppliers who offer:

- Tested and Verified Engines: Engines should undergo rigorous inspection to ensure all critical systems, including the fuel system, turbochargers, and cooling components, are functioning properly.

- Documentation: Suppliers should provide records detailing the engine’s history, inspection results, and compatibility with specific truck models.

- Warranty Coverage: This offers protection against early defects or mechanical issues, providing confidence in the purchase.

Nationwide Truck Parts LLC is the nation’s #1 retailer of used diesel engines, specializing in late-model Cummins, Detroit, CAT, and Paccar units. Their expertise ensures that buyers searching for an x15 engine for sale gain access to thoroughly tested engines that meet strict quality standards. All engines are prepared to perform reliably, reducing the risk of early failures and ensuring consistent fleet performance.

Evaluating Engine Performance

Regular performance evaluation is key to maintaining reliable operation. Operators should monitor:

- Fuel Efficiency: Assessing how effectively the engine converts fuel into power helps identify inefficiencies or potential mechanical issues.

- Oil Pressure and Consumption: Low pressure or excessive consumption may indicate internal wear or leaks.

- Exhaust and Emissions: Changes in smoke color or unusual odors can signal combustion issues or failing components.

- RPM and Power Delivery: Ensures consistent performance under various loads.

Operators can benefit from using diagnostic tools to track these parameters. Engines sourced from trusted suppliers like Nationwide Truck Parts LLC are typically tested for these performance indicators before being made available, ensuring reliability from day one.

Selecting the Right Engine for Your Fleet

Choosing the correct engine model depends on operational requirements and route types:

- Long-Haul Operations: Engines like the Cummins X15 provide high torque and fuel efficiency for extended interstate travel.

- Regional or Local Hauling: Detroit DD15 and Paccar MX-13 engines balance power and fuel efficiency for moderate distances and frequent stops.

- Heavy Vocational Work: CAT C15 engines are ideal for high-stress applications, maintaining performance even under demanding loads.

Working with an experienced supplier ensures operators receive engines that have been carefully inspected and tested. Nationwide Truck Parts LLC offers access to late-model engines suitable for various operational needs, including the x15 engine for sale, ready to perform reliably in heavy-duty trucking environments.

Maintenance Best Practices

Even high-quality engines require consistent maintenance to ensure longevity. Key practices include:

- Routine Oil and Filter Changes: Using the recommended grade and quality of oil prevents internal wear and preserves engine performance.

- Coolant System Checks: Maintaining proper coolant levels prevents overheating and thermal stress.

- Inspection of Belts, Hoses, and Seals: Detecting wear or leaks early prevents minor issues from escalating into major failures.

- Turbocharger and Exhaust Monitoring: Ensures efficient performance and reduces the risk of costly damage.

Integrating these practices with high-quality engines from trusted suppliers forms the foundation for long-term reliability.

Preventive Measures for Engine Longevity

Beyond regular maintenance, operators can extend engine life through preventive measures:

- Operating Within Recommended Limits: Avoid overloading the engine or exceeding designed capacities.

- Limiting Idling: Reduces unnecessary wear and conserves fuel.

- Balanced Load Distribution: Evenly distributes stress across the drivetrain and suspension system.

- Warm-Up Periods: Allow engines to reach optimal operating temperature before heavy use to prevent thermal stress.

- Controlled Storage Conditions: Protect engines from extreme weather, moisture, and dust during inactivity.

- Operator Training: Educated drivers who monitor engine performance and adopt fuel-efficient practices help prevent premature wear.

Adopting these strategies helps maintain consistent engine performance and prolongs the lifespan of used diesel engines.

Sourcing Trusted Suppliers

Selecting a dependable supplier is essential for operational reliability. Key considerations include:

- Extensive Inventory: Ensures the right engine model and components are available.

- Nationwide Shipping: Reliable logistics minimize downtime and ensure timely delivery.

- Technical Support: Expert guidance helps operators select compatible engines and maintain them effectively.

Nationwide Truck Parts LLC exemplifies these qualities. As the nation’s leading provider of used diesel engines, they specialize in late-model Cummins, Detroit, CAT, and Paccar engines. Their commitment to inspection, testing, and nationwide service guarantees operators can source engines, including the x15 engine for sale, with confidence and peace of mind.

Final Thoughts

Selecting and maintaining a high-quality diesel engine is critical for fleet efficiency and reliability. Combining careful engine selection, routine maintenance, preventive measures, and sourcing from trusted suppliers ensures trucks remain dependable and cost-effective. Engines like the Cummins X15, Detroit DD15, CAT C15, and Paccar MX-13 provide durable solutions for a wide range of applications, especially when sourced from verified providers.

By following best practices in sourcing, maintenance, and operation, operators can maximize engine lifespan, reduce downtime, and maintain consistent performance. High-quality used engines, including options such as an x15 engine for sale, provide years of reliable service when paired with diligent care and professional supplier support.