Contract Engineering – Accelerating Product Development in the Medical Device Industry

Medical devices save lives, but their journey from idea to finished product is rarely straightforward. Companies face complex regulations, evolving technologies, and competitive pressure to deliver safer and more effective solutions quickly.

The global medical devices market is set to reach an impressive revenue of $539.82 billion by this year. Sadly, even though the sector is growing rapidly, many organizations, especially startups and mid-sized firms, find themselves limited by time, resources, or specialized knowledge.

This is where the need for contract engineering comes in.

Why Contract Engineering Matters in Medical Device Development

Unlike other industries, medical devices undergo strict approval processes before reaching the market. Every project must demonstrate safety, accuracy, and reliability. Small delays in development can mean missing market windows or losing investor confidence.

Contract engineering offers companies the flexibility to scale up their teams when needed. As of 2024, the global medical device contract manufacturing market is worth $76.8 billion. By turning to experienced professionals, companies can avoid overburdening internal staff and keep projects moving on schedule.

As Gener8 notes, such services offer their customers decades of industry knowledge, expertise, and leadership. This, in turn, guarantees customer success through innovative strategies and planning.

Contract work also reduces the risks tied to long hiring processes. Instead of recruiting and training full-time employees, businesses gain immediate access to expertise. This flexibility ensures that product development continues at a steady pace, even when specialized knowledge is required.

Access to Specialized Expertise

The medical device industry demands a diverse set of skills, from mechanical design to electrical engineering and software development. Few companies have every discipline in-house. Contract engineering solves this by connecting organizations with professionals who already possess the required expertise.

For instance, one project may require a biomedical engineer with experience in imaging devices. Another project might call for a specialist in low-power electronics.

Now, in the US, biomedical engineers earn an average annual salary of $90,742. Power electronics engineers, on the other hand, average a salary of $130,559 per year. Hiring these individuals at such high salaries is difficult for many manufacturers, especially startups.

With contract work, companies do not need to maintain full-time positions for each niche skill. Instead, they can engage the right expert at the right moment. This focused service reduces overhead costs and ensures that every stage of development benefits from top-tier knowledge.

Supporting Innovation at Every Stage

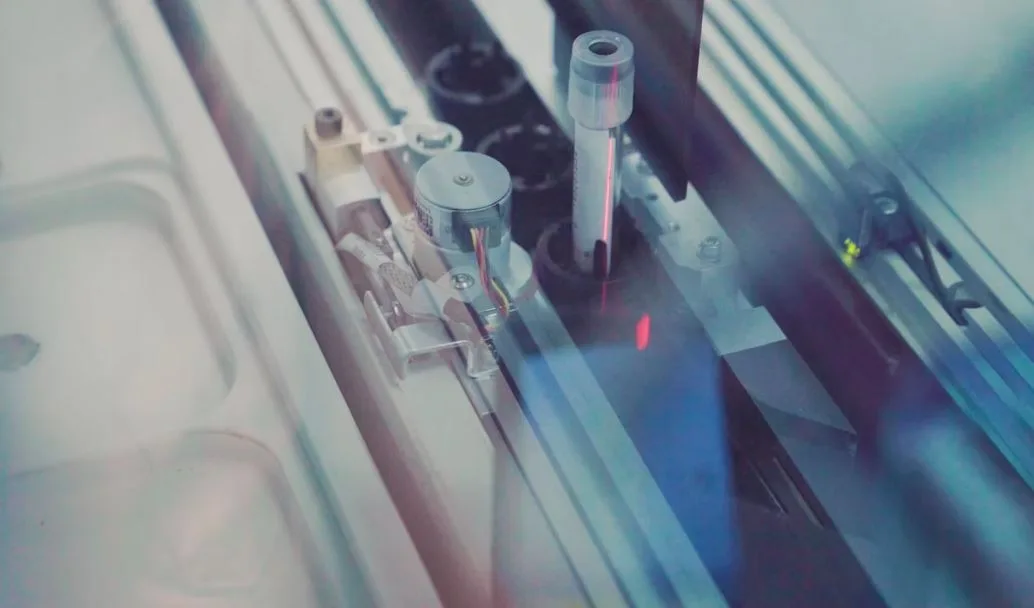

Medical devices often move through phases of concept, prototyping, verification, and validation before reaching the market. Contract engineering can support product development at each step.

In early stages, outside professionals may help transform ideas into workable designs. During prototyping, they can advise on materials, manufacturing methods, and compliance with standards. Later, they may contribute to testing and data analysis that ensures safety and performance.

For many companies, these services shorten the time between concept and launch. Instead of facing bottlenecks caused by limited in-house capacity, they can rely on contract work to keep projects advancing.

Meeting Regulatory Demands with Confidence

One of the greatest challenges in the medical device industry is navigating regulations. Products must meet international standards for safety, usability, and effectiveness. Small mistakes can result in costly delays or failed approvals.

Professionals working in contract engineering often bring deep familiarity with these requirements. Their expertise can help companies avoid compliance errors during product development.

Whether it involves documentation, risk assessments, or testing protocols, having skilled contract engineers on board reduces uncertainty. Instead of approaching regulations as obstacles, companies can address them as part of a structured and efficient process.

This confidence allows product teams to focus on innovation while knowing that critical standards are being met.

Reducing Risks and Costs

Hiring full-time specialists for every role is rarely practical. Salaries, benefits, and training costs quickly add up.

Contract engineering provides a cost-effective alternative. Companies pay for the specific service they need, when they need it. This model reduces financial risk while ensuring that projects benefit from high-level expertise.

At the same time, contract work helps companies avoid expensive mistakes. Experienced professionals bring lessons learned from previous projects, which minimizes trial and error. The result is smoother development, fewer redesigns, and a faster path to market approval.

Frequently Asked Questions (FAQs)

Why are medical devices so expensive to manufacture?

Medical devices are costly to produce because they must meet strict regulatory standards, go through extensive testing, and use high-grade materials. Unlike consumer electronics, devices like pacemakers, surgical tools, or diagnostic machines cannot fail, since lives depend on them. The costs of research, clinical trials, regulatory approvals, and maintaining sterile manufacturing facilities add significantly to the price.

What is a medical device contract manufacturer?

A medical device contract manufacturer is a company that specializes in producing devices for other companies that design or sell them. Instead of building their own factories, many medical device companies outsource production to these manufacturers, who already have the expertise, equipment, and certifications required. This helps reduce costs, speed up production, and ensure compliance with industry standards while letting the original company focus on design, innovation, and marketing.

What is quality engineering in the medical device industry?

Quality engineering in the medical device industry ensures that every product is safe, reliable, and compliant with regulations before it reaches patients. Quality engineers design and implement processes to prevent defects, verify product performance, and document compliance for regulatory bodies like the FDA. Their work spans everything from risk analysis to testing, audits, and continuous improvement.

The medical device industry is under constant pressure to innovate while meeting rigorous standards. For many organizations, contract engineering offers the perfect balance of speed, expertise, and cost efficiency.

By engaging professionals through contract work, companies accelerate product development, meet regulatory demands, and reduce financial risks. In a field where every day counts, contract engineering is helping medical device companies deliver life-changing solutions with greater confidence and speed.