Exploring GRP Honeycomb Panels: Lightweight Strength for Modern Construction

In today’s fast-evolving construction landscape, innovation in materials plays a pivotal role in enhancing efficiency, sustainability, and structural performance. Among the standout materials gaining traction across industries are grp honeycomb panels. Known for their unique combination of strength and lightness, these panels are transforming how architects and engineers design modern structures. Whether it’s in transportation, infrastructure, or modular buildings, the relevance of GRP (Glass Reinforced Plastic) honeycomb panels is rising rapidly due to their unmatched utility and adaptability.

As traditional materials like metal and wood face challenges in terms of weight, maintenance, and durability, industries are shifting toward composites. GRP honeycomb panels are an ideal solution, offering high structural integrity with minimal weight. Their honeycomb core, typically made from materials such as aluminum or polypropylene, enhances performance without adding bulk. Let’s delve into the properties, advantages, and applications of this game-changing construction element.

What Are GRP Honeycomb Panels?

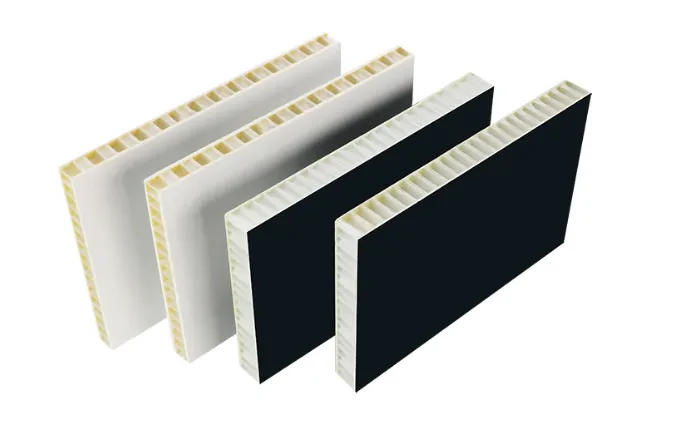

GRP honeycomb panels are engineered composite panels consisting of a core layer arranged in a honeycomb structure and reinforced with GRP skins on both sides. This combination makes them rigid yet lightweight, making them suitable for various high-stress and low-weight applications. The core structure mimics the geometry found in nature similar to a beehive which provides exceptional compression resistance and stability.

The outer GRP layers offer resistance to environmental and chemical exposure, moisture, and impact damage. Depending on the intended use, these panels can be customized in terms of thickness, core material, and surface finish. Because of this versatility, manufacturers can tailor GRP honeycomb panels for specific industry standards and performance requirements.

Advantages of GRP Honeycomb Panels in Construction

The construction industry continuously demands materials that are durable, economical, and sustainable. GRP honeycomb panels meet all three requirements effectively. One of their biggest advantages is their superior strength-to-weight ratio, which allows builders to reduce the load on supporting structures and foundations. This is especially useful in multi-story buildings or applications involving large spans.

Another key benefit is their resistance to corrosion, which is crucial in harsh environmental conditions. Unlike metal, which can rust or degrade over time, grp honeycomb panels retain their structural integrity even when exposed to water, chemicals, or salty air. Their non-conductive nature also makes them ideal for electrical and telecommunication applications where insulation is necessary.

Versatile Applications Across Industries

The utility of GRP honeycomb panels extends far beyond just residential or commercial construction. In the transportation sector, these panels are used extensively in the manufacturing of trains, buses, and aircraft interiors. Their lightweight nature contributes to fuel efficiency without compromising safety or rigidity. In marine environments, GRP panels are employed in boat hulls, decks, and interior partitions, offering longevity even in continuous exposure to water.

Moreover, temporary and modular structures such as site offices, mobile clinics, and event booths benefit from the rapid installation and portability of GRP honeycomb systems. Because these panels are easy to fabricate and install, they significantly reduce labor and time costs, an advantage appreciated across time-sensitive projects.

Sustainability and Environmental Impact

With the global focus shifting towards eco-conscious construction, grp honeycomb panels are proving to be a forward-thinking material. Their long life span reduces the need for frequent replacements, minimizing resource consumption. Additionally, because the panels are lightweight, transportation requires less fuel, thereby reducing carbon emissions during logistics.

Recyclability is another key feature. Many manufacturers now offer panels with recyclable or partially recycled cores, contributing further to environmental responsibility. By incorporating GRP honeycomb panels into construction designs, architects and builders are embracing a low-carbon alternative that doesn’t compromise on quality or strength.

Fire Resistance and Safety Considerations

Safety is a primary concern in both public and private buildings, and GRP honeycomb panels are developed with this in mind. Modern manufacturing techniques allow for the inclusion of fire-retardant additives that enhance the panel’s performance under high temperatures. These fire-rated panels help in compartmentalization and delay the spread of fire, offering critical time for evacuation.

Their non-toxic nature is also important. Unlike some traditional materials that release harmful gases when exposed to fire, grp honeycomb panels can be engineered to emit minimal smoke and toxins. This feature is increasingly being prioritized in the construction of schools, hospitals, and other sensitive environments.

Installation and Maintenance Benefits

Ease of installation is one of the unsung benefits of GRP honeycomb panels. Their lightweight property reduces the need for heavy lifting equipment, which not only lowers costs but also enhances worker safety on-site. Panels can be pre-fabricated off-site to precise dimensions and assembled quickly once delivered, thereby streamlining construction timelines.

In terms of maintenance, GRP panels outperform many conventional materials. They are resistant to rot, mold, and mildew factors that often lead to costly repairs in wooden or poorly insulated structures. A simple cleaning regimen is usually sufficient to maintain their appearance and functionality, making them a practical choice for long-term projects.

Customization and Aesthetic Versatility

Beyond functionality, grp honeycomb panels also offer aesthetic flexibility. They can be produced in a wide range of colors, textures, and finishes to match architectural themes or branding requirements. Whether the goal is a sleek, modern façade or a textured interior wall, GRP panels can be designed to achieve the desired visual impact.

Moreover, these panels support integration with other materials such as glass, metal, or wood veneers, enabling hybrid solutions that blend form with function. In the retail and hospitality sectors, this versatility makes them highly desirable for both decorative and structural use.

Cost-Efficiency and Long-Term Value

Although the initial cost of GRP honeycomb panels might be slightly higher than some traditional materials, their long-term value far outweighs this. Reduced installation time, lower maintenance, and extended durability translate into cost savings over the panel’s lifetime. Additionally, their insulating properties contribute to energy efficiency, helping to cut heating and cooling expenses.

In high-volume projects or repeatable modular designs, these savings are compounded. Builders and developers who invest in grp honeycomb panels often find that the ROI justifies the upfront investment, especially when long-term sustainability is a project priority.

GRP Honeycomb Panels in Future Infrastructure

Looking forward, the role of GRP honeycomb panels in infrastructure development is only set to expand. As urbanization accelerates and smart cities take shape, the demand for materials that are not only durable but also adaptive and efficient will increase. These panels are already being used in cutting-edge projects such as green buildings, disaster-relief shelters, and aerospace infrastructure.

With continuous advancements in composite technology, future iterations of GRP honeycomb panels may feature even greater strength, lighter cores, and integrated smart functionalities like thermal sensors or solar reflectivity. Their adaptability and resilience make them a top contender for shaping the future of modern construction.

If you’re searching for an innovative material that offers a perfect balance between strength, durability, and sustainability, grp honeycomb panels are undoubtedly worth considering. Their proven advantages across industries and environments affirm their status as a smart solution for today’s construction challenges.