Exploring the Versatility and Benefits of Hollow Board in Modern Construction Projects

Hollow board has transformed construction possibilities, as modern projects require versatility and the highest level of practicality. From light yet sturdy materials to sustainable uses, hollow boards are changing the structure, design, and efficiency optimization. This article intends to go into every aspect that makes hollow board a favorite of architects, builders, and project managers. Whether it’s improving sustainability, cutting costs, or providing more design flexibility, the article will demonstrate why hollow board is quickly becoming a building block of newer construction techniques. Find more info now

Understanding Hollow Board and Its Applications

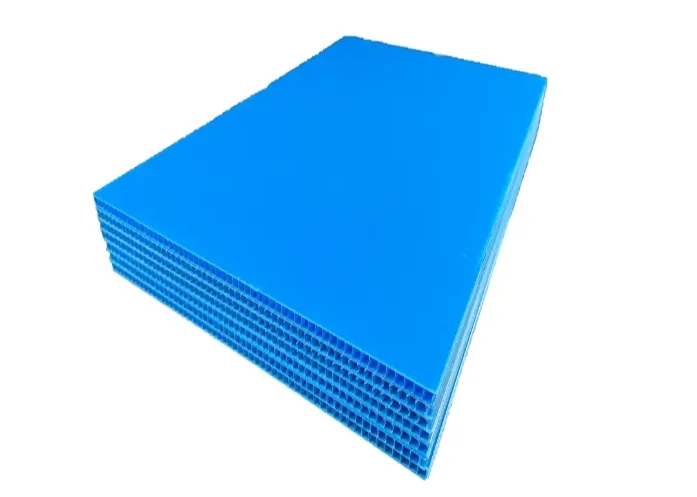

What is Hollow Board?

A hollow board is a lightweight, heavy construction building material. In other words, it is made with a structured core that reduces weight while still retaining strength. Generally, they are regarded as highly versatile because they are usually made of thermoplastics such as polypropylene or polycarbonate, or even of recycled materials. Their hollow-ribbed structure saves material while giving superior insulation, impact resistance, and flexibility. This design enables their applications in many industries, including construction, packaging, advertising, and transport. These factors make them even more attractive to modern builders who consider moisture resistance, chemical resistance, and UV resistance as options for an economical, sustainable solution. Thus, with all this innovation, the hollow board has progressed to become the prime building material in sustainable and efficient projects.

Key Characteristics of PP Hollow Boards

The unique characteristics that qualify PP hollow boards for several applications are, primarily, their ease of handling and transporting because of their lightweight yet sturdy structure. Thin yet very thick in resistance to shocks, they fit places where material conditions are to be rough. Their excellent moisture resistance might also prevent warping and degradation in humid conditions, hence boosting longevity and performance.

Another important property is the versatility of PP hollow boards. These can be fabricated in varying sizes, thicknesses, and colors to fulfill custom project demands. Being recyclable and eco-friendly, these are embraced by modern sustainable practices to limit environmental impact. Finally, PP hollow boards serve as an excellent form of thermal and acoustic insulation. Hence, it becomes a preferred choice for industries and homes where energy efficiency and noise reduction are of concern. Together, these attributes make PP hollow boards a versatile and innovative material solution.

General Applications in the Building Industry

Since they have multifunctional properties that are highly adaptable, these hollow boards have received their rightful share of attention from the construction world. Using them to erect temporary partitions on construction sites involves a lighter material that is high in strength and easy to handle and assemble. Likewise, they protect floors, walls, and other surfaces during phases such as construction or remodeling, which could be damaged if heavy machine tools or debris come into contact with them. Their waterproof quality ensures they are useful in formwork applications exposed to moisture, including setting concrete. In other words: avoiding deformation under wet conditions. Building signage and scaffolding panels represent other applications for PP hollow boards, which are sustainable substitutes for conventional wood or metal materials, thus supporting current initiatives to reduce environmental impact in construction processes. Versatility, together with cost-effectiveness and reusability, make PP hollow boards a must-have material for a plethora of construction applications.

The Advantages of Using Hollow Composite Decking

Durability and Weather Resistance

Hollow composite decking is crafted to withstand weather variations, thus making it apt for both residential and commercial projects. Being moisture-resistant, these boards repel cracking and warping: hence their long life in an outdoor setting. This, along with their protective coating that prevents surface fading from prolonged UV exposure, guarantees that they retain their look throughout their life. In stark contrast to wood, composite decking is relatively easy to manage as it is resistant to mold and insect infestation. Hollow composite decking can thus provide all the functionality a weather-resistant surface requires, offering a good price for its looks and meeting the needs for durable, low-maintenance outdoor surfaces.

Cost-Effectiveness Compared to Traditional Materials

From a mere investment perspective, cost-efficiency makes hollow composite decking a wise option for homeowners and businesses alike. Of course, the initial price tag of composite decking is higher than that of traditional materials such as timber; still, the long-term savings it provides are well worth the initial investment. Wooden decking is usually treated and sealed periodically to resist wear and environmental effects. Maintenance of this type accumulates costs over time and demands constant attention and resources. Thus, wooden decking maintenance is costly and time-consuming. Being free from maintenance expenses is a key advantage of composite decking: merely cleaning it now and then to keep it looking good is all that composite decking demands from its users.

Including the longevity of hollow composite decking in its list of economic benefits is also noteworthy. Due to rotting, warping, and insect attacks, traditional materials require frequent replacements, which adds to the cost of delivery. These common hindrances do not affect composite decking, which is made of sturdy synthetic and natural materials that promise a longer life and thus a temporary necessity for replacement. Also, most composite decking uses recycled products during manufacturing, thereby lowering environmental impact. Many such products may qualify for incentives or credits, providing additional value for the environmentally conscious.

Composite decking is super durable and hence stays beautiful over time, lessening any need for refurbishing or updating. Those seeking the utmost durability, beauty, and environmental friendliness for their home or business will find composite decking to be an ideal solution, offering the perfect balance of ecological investment and cost that pays off over time.

Environmental Benefits of Composite Decking

Composite decking is the greener choice as against traditional wood decking, which welcomes bringing such debilitating effects upon the environment tied to outdoor projects of construction. Made from recycled wood fibers and plastics, composite decking helps store materials that would otherwise fill up landfills. This process helps reduce a considerable amount of waste and dirt, thereby preventing the need to obliterate trees, which would actually have been necessary for life.

Composite decking also scores heavily on longevity and ease of maintenance. Unlike timber, chemical treatments, stains, or sealants are unnecessary for it, and such chemicals very often may pollute the environment. Since it is durable and lasts for a long time, instances of replacement are fewer over time, resulting in less resource consumption. Composite decks present a more sustainable solution for environmentally conscious homeowners or businesses because they offer longevity to protect the Earth.

Comparing Hollow Board Products in the Market

Different Types of PP Hollow Boards

Possessing lightweight structures, durability, and adaptability, polypropylene (PP) hollow boards are versatile products used in countless industrial applications. Given their wide variety of designs and manufacturing procedures, as well as the targeted end-use, they are classified into:

Standard PP hollow boards: As any general-purpose application would require, they’re strong and weather-resistant. These would generally be typical applications for packaging, storage, and building purposes. They are lightweight, making them easy to handle. Their resistance to moisture and chemicals ensures that they can be applied in both indoor and outdoor conditions.

Fire-retardant PP hollow boards: These are flame-retardant types used in hazardous environments, such as construction sites or warehouse storage. Fire-retardant additives are incorporated into the manufacturing process of these boards, which reduces their flammability and enhances safety without compromising their structural integrity.

Anti-Static PP Hollow Boards: These special hollow boards inhibit the generation of static electricity and consequently find usefulness in the packaging and storage of electronics. Their use reduces the likelihood of an electrostatic shock occurring, which could destroy a sensitive electronic component.

UV-Resistant PP Hollow Boards: These have improved resistance to UV radiation and are therefore especially suitable for long-term outdoor use. Advertising signboards, agricultural purposes, protective barriers, etc., are some of the applications that benefit from being placed under the sun.

Customizable PP Hollow Boards: For special requirements, companies produce boards that can be customized in dimensions, thickness, and features such as printing and lamination. These boards are designed for special applications where a solution is needed to meet user-specific needs.

Each type of PP hollow board has unique benefits, depending on the application, resulting in efficient and sustainable usage in one domain or the other. With thorough knowledge of the specifications and benefits of these types, a keen businessman or consumer can select the type that best fits their particular requirement.

Leading Brands and What They Offer

Some leading manufacturers dominate the PP hollow board market by concentrating on providing innovative solutions and ensuring guaranteed quality. These pioneers in the industry, therefore, range in options proposed to suit specific industrial and commercial requirements:

- Coroplast: Coroplast is said to be one of the best producers of corrugated plastic sheet material, including PP hollow boards. Their products are produced in various thicknesses, colors, and finish-type applications, including signage, display, and packaging. Coroplast also claims to be environmentally friendly, emphasizing the recyclability of the product and environmental responsibility.

- Inteplast Group: The Inteplast Group deals in the durable PP hollow boards under its high-performance industrial plastics division. Their boards are distinguished by advanced manufacturing techniques, bringing excellent qualities of impact resistance, water resistance, and weatherproofing. Such properties make forecasts from Inteplast very popular in the construction, agriculture, and logistics sectors.

- Primex Plastics: With more than 50 years of experience, Primex Plastics has developed a broad product array catered to meet the needs of a vast array of industries. These PP hollow boards are produced in custom sizes and are sometimes treated with UV protection or anti-static coatings for enhanced durability and specialized performance.

- Karton Group: based in Europe, Karton Group deals in lightweight yet versatile PP hollow boards. The brand caters to protective packaging and returnable transport themes, having high-quality and conscientious credit attached to sustainable manufacturing processes.

- A&C Plastics: A&C Plastics is well-known for excellent customer service and innovative inventory solutions designed to provide versatile PP hollow boards, serving industries such as graphic arts and construction. The boards supply the most excellent surface finish and mechanical strength required for demanding applications such as commercial displays, temporary shelters, and more.

The new arenas for advancement in PP hollow board have been continuously opened, focusing on new technology and user-oriented design, with quality, reliability, and sustainability as key factors.

Choosing the Right Hollow Board for Your Project

Your project requires careful consideration of several factors when choosing the perfect PP hollow board. First of all, consider thickness-weight specifications, which in turn determine durability and load-bearing capacity. Thicker boards would be used for heavy-impact work like construction panels, while lighter ones would be used for promotional displays or packaging.

Afterward, one has to consider the environmental conditions their project is going to face. For outdoor uses, one needs to ensure that the boards have UV resistance and are partially water-repellent to prevent exposure to sunlight and moisture from eating away at them. Interior-use boards might prioritize an aesthetic finish or ease of handling.

Also, slick may be considered in the assessment of the life expectancy of the boards. Temporary uses, such as temporary structures or election signage, should be cost-effective, whereas more permanent uses would require boards of a higher grade with increased resistance and durability.

Specific applications, such as those in logistics or retail, may benefit from features like anti-static coatings, fire retardancy, or enhanced printability for branding purposes. These modifications serve specific functional or aesthetic requirements, enhancing efficiency and visual appeal.

Lastly, take into account sustainability factors, especially if the environment is a concern for your plan. Many manufacturers now offer green solutions: such as recyclable PP hollow boards that combine performance and sustainability, leaving almost no footprint on nature.

Considering all the factors will ensure you pick a hollow board that performs optimally, both in practice and environmentally.

Installation and Maintenance of Hollow Composite Decking

Installation Guidelines and Best Practices

Hollow composite decking should be installed correctly to achieve durability, stability, and maximum performance. First, prepare the site by leveling it and removing debris before laying the foundation. Joists or subframes made of treated wood or metal should be used to lay the deck so it will not get damaged by moisture or pests over time.

Allow sufficient space between the boards to accommodate thermal expansion and contraction, as the composite material might expand slightly with temperature changes. Fasten the boards using hidden fasteners or screws made for composite decking that ensure a clean finish. Always follow the manufacturer’s instructions for placing screws to prevent the mixture from cracking or weakening.

To achieve a longer lifespan, proper drainage must be considered: slope the deck away from buildings to avoid water seeping in. The use of end caps or edging will keep hollow boards intact and lengthen their lifespan even further. Do not cut corners during installation: a well-measured and aligned deck makes all the difference aesthetically and functionally. The end product will be a sturdy, visually pleasing deck that will last.

Maintenance Tips for Longevity

Regular maintenance ensures your decking remains in excellent shape. Sweep the deck often of debris such as leaves, dirt, and other matter, as they trap moisture, thereby aiding the growth of mold or mildew. For a deeper clean, apply a non-abrasive deck cleaner with a soft brush to create a protective surface treatment, removing stains or material buildup without damaging the surface. Steer clear of pressure washing, since this can damage the material, causing splintering in the long run.

If you want to raise the resistance of your deck against moisture and UV damage, the next step would be the yearly application of a protective sealant, according to the manufacturer’s recommendation. Periodically check for loose screws, warped boards, or any signs of wear to repair them immediately, lest they create further problems. With a bit of adoption in preventive care, the look and sturdiness of the deck will be preserved, ensuring it remains a safe and secure space for a long time.

Common Troubles and Remedies

Warping and Cracking: Both warping and cracking are common defects encountered in decks subjected to fluctuating weather. These difficulties arise due to water ingress or prolonged sunshine. Wanda, to keep the water at bay and reduce UV damage, make sure the deck is well-sealed. Ideally, top-quality and weather-resistant materials should also be employed to reduce the costs associated with these problems during construction. Should the deck boards warp or crack, promptly remove the damaged ones; this will ensure the safety and structural integrity of the deck.

Mold and Mildew Growth: Mold and mildew need a wet surface to grow on, so decks are apt to develop them, especially in gloomy and humid areas. Cleaning with a mild cleaner suitable for decks can remove dirt and prevent the accumulation of organic debris that serves as a food source for growth. There should also be sufficient ventilation under and around the deck, and it should be treated with anti-fungal chemicals to prevent mold and mildew from developing.

Loose or Rusty Fasteners: Fasteners might loosen or rust over time, caused by use and weathering, respectively. Regular inspections prevent problems from getting bigger by spotting them early. Tighten loose screws; fasteners showing signs of rust must be replaced with weather-resistant ones, such as stainless or coated screws. Proper fastening is instrumental in maintaining the stability and safety of the decking.

Fading And Discoloration: Sunlight causes fading and discoloration, which would then diminish the beauty of the deck. Application of UV-resistant finishes or stains at the time of installation will retain the pendant’s bright look. When fading shows up, refinishing or re-staining is one way to restore the color while protecting the wood from further sun damage.

Structural Weakness: Over time, decks may develop structural weaknesses due to wear and tear or lack of proper maintenance. Signs of structural problems include sagging, wobbling, or creaking. These issues should be addressed promptly by reinforcing the weak areas or having a professional evaluate the deck. Avoidative repairs go a long way for safety and longevity.

Knowing these common problems and using specific remedies should extend the life of your deck while keeping it appealing, useful, and secure for everyday use.

Shipping and Availability of Hollow Board Products

Where to Purchase Hollow Board and Composite Decking?

Where to buy hollow boards and composite decking depends on the individual’s needs and preferences. The best place to start looking is from online marketplaces, which include Amazon and Home Depot. These platforms offer a wide selection of composite decking materials, including hollow boards, at competitive prices. They usually provide detailed product descriptions, customer reviews, and multiple shipping options, making it easy to compare and select products for one’s project.

If you wish to buy directly from the producer or a store that specializes in decking in your locality, that’s another great choice. Websites for the biggest brand names, including Trex, TimberTech, and Fiberon, enable you to view their complete offerings of composite decking materials. Most of these companies provide design ideas, product calculators, and even samples for free; all of which would help you make well-informed decisions. This also guarantees that the products sold to you are original and of high quality.

You can also explore your materials by visiting local home improvement centers or lumber yards. Lowe’s, Menards, and independent building supply stores are apt to carry hollow boards and composite deckings. The in-store staff may enlighten you on installation, maintenance, and customization possibilities. Thereby, both online and offline shopping present you with numerous options to guide you in selecting decking materials perfect for one of your projects.

Shipping Considerations and Costs

There are a few considerations that the entrepreneur should keep in mind while shipping construction materials to ensure speedy and cost-effective delivery. From my personal experience, it is evident that shipping prices may differ depending on the material, the supplier, or the delivery place. Heavier options of shipping may include composite or hardwood decking, while hollow boards are generally cheaper to ship since they weigh less. It might be more affordable if a store offers flat-rate shipping or free shipping for orders that exceed a particular amount, if you are ordering a large quantity. It never hurts to shop around and compare shipping policies to find the most cost-effective way.

Timing is of utmost importance. In my experience, standard shipments of decking materials can take about 5 to 10 working days. If you want to expedite delivery, of course, you can usually pay extra. Some suppliers also allow scheduling delivery times to suit your convenience, which can be very useful when the project timeline is tight. It is also worth noting that delays can sometimes occur due to supply chain disruptions or seasonal demand; therefore, planning will be crucial.

Finally, pay particular attention to the delivery logistics. Most decking materials are generally delivered in bulk and require unloading by special equipment. For instance, some will come on pallets, so you may need a forklift or extra labor to unload. Always check with your supplier before delivery to avoid any unwelcome surprises. Foresight and thorough research can save you money and put your mind at ease should your decking materials ever need shipping.

Market Trends for Hollow Products

It is evident from the analysis I performed on the variety of hollow products that there has been an ever-increasing demand due to their lightweight, inexpensive, and eco-friendly nature. Manufacturers continue to work on new technologies to enhance the strength of materials while retaining their core advantage of being lightweight. For example, hollow decking boards remain profitable with buyers, mainly contractors and DIYers, because they are much cheaper than solid ones. Their ability to sustain moderate-foot-traffic loads means the boards do not lose much durability due to their low price. Recent processes in manufacturing, such as co-extrusion and composites, have further augmented their resistance to weathering and abrasion, thus making them attractive to markets in different climates.

Another key driver sculpting the hollow product demand is sustainability. Most of these items incorporate recycled materials, in tune with global sustainability trends and changing customer preferences. The construction and packaging industries might increasingly promote products made of recyclable plastics and environmentally friendly composites as green alternatives. This marks a shift in consumers’ awareness of the environmental impact of products, and they are urging industries to adopt a circular economy. Alongside that, regulatory frameworks in many countries aimed at reducing waste and increasing the usage of recycled materials drive the growth of this market.

Finally, with the ever-shifting global supply chain dynamics, hollow products have gained popularity due to cheaper shipments. That is because these hollow products, being of lesser weight than their solid counterparts, imply lower transportation charges and thus a favorable choice for large projects or international shipments. And with these cost savings in a competitive market setting, where price is paramount, this proposition becomes desirable. All these trends stand for a promising and upbeat growth trajectory for hollow products, fueled by a mix of innovation, sustainability, and cost-effectiveness.

Frequently Asked Questions (FAQs)

What are the advantages of hollow boards in construction?

Hollow boards offer diverse advantages in construction: lightweight and durable. Since they are made of polypropylene or similar materials, they resist moisture and won’t warp, making them extremely useful in diverse applications. Because these boards last so long, one will not have to purchase replacements continuously and can save on the price in the long run. Also, they are stronger than the usual wood or MDF boards and thus can be used for many purposes in residential and commercial construction. Besides being a stronger solution, this choice is also ecological since many manufacturers produce these boards using recycled materials.

How do pp hollow boards compare with traditional wood boards?

Hollow PP boards differ much from the traditional wood boards in terms of weight and durability. Wood warps under moisture and temperature changes, whereas polypropylene remains intact under weather conditions. In addition, hollow boards are made to be lighter for easier transportation and installation. They sometimes behave just like wood, used for furniture or partitions. They also require less maintenance than wood; hollow boards can never grow mold or decay.

What is the ideal hollow board size for DIY work?

The ideal thickness for hollow boards in DIY projects can vary with specific applications. Usually, 12mm wide boards are considered best for ensuring sturdiness as well as being easy to handle. Quite larger dimensions than this could be preferred for furniture production to maintain structural integrity, while smaller ones usually suffice for decorative partitions or light storage. Ensuring design intent and functionality will weigh heavily on the selection of sizes! And, of course, space available for installation will also factor into that choice. Always check the manufacturer’s recommendations for compatibility with any related products.

Are hollow composite decking materials suitable for outdoor use?

Because they resist weather changes, these hollow composite decking materials are perfect for outdoor applications. When exposed to sunlight, these boards will not splinter, warp, or fade, making them great for patios and deck areas. Most composite materials incorporate recycled plastic elements that contribute to even more durability and sustainability. Composite decking systems, which include hollow boards, require less maintenance compared to timber solutions; hence, owners do not necessarily have to paint or stain them regularly. Checking the manufacturer’s spec sheet is necessary when working on an outdoor project to choose the right product for your designs.

Can hollow boards be used for furniture manufacturing?

Well, hollow boards are fine for making furniture. They are lightweight and sturdy enough to lead the simple life—that is, just be functional—tables, chairs, etc. Apart from these obvious uses, the boards can be engineered to look impressively smooth, thereby pleasing the eyes of a residential or commercial space. Being made of polypropylene also means that these boards have a certain resistance to moisture, a feature worth considering if your furniture interacts with high humidity. Consideration needs to be given to the strength and stability of furniture designed with hollow boards to ensure it is longer-lived.

What things should be considered to select the distributor for hollow boards?

Several factors should be taken into consideration while choosing a distributor for hollow boards. First, consider the quality of products and whether they can meet industry standards in terms of durability and functionality. Then comes the question of the availability of sizes and types, and whether related products are offered that can complement your application. Shipping options and charges are equally important if your project involves large-scale operations and requires bulk orders. Finally, customer service and support are crucial because a competent distributor can assist you in making purchase decisions.