Exploring the Versatility of Hollow PVC Board for Creative Architectural Solutions

On a parallel note, innovations and improvements in construction materials continue to push the frontiers of contemporary architecture, allowing designers and builders to work on projects that offer utility, durability, and artistic beauty. Hollow PVC boards, among these inventions, stand as a panacea, offering unmatched versatility for various architectural applications. From light structural work to magnificent and elaborate decorative beauty, this material has brought forth a new approach for professionals to design. This article provides an in-depth exploration of the unusual features of hollow PVC boards, emphasizing their advantages as structural components, for creativity, and in environmentally friendly uses. Join us as we learn how this highly versatile material is helping to shape the future of architectural expression. Click here to read more

Introduction to Hollow PVC Boards

What Is Hollow PVC?

The so-called hollow PVC, or Polyvinyl Chloride, is essentially an extremely lightweight yet very strong material produced from a polymer blend. Making distinctions from solid PVC, hollow PVC has a core with a void inner structure, which helps reduce its weight without markedly compromising its structural integrity. This material is highly appreciated for its extraordinary ratio of strength to weight, as well as its resistance to moisture, rot, corrosion, and thermal expansion. Hollow PVC boards are created by advanced extrusion processes, which permit them to control dimensions and properties quite precisely; hence, demanding architectural and industrial applications are well within their scope. Their non-toxic nature is also attributed to their recyclability, which further fosters their use in sustainable design efforts.

Benefits of Using Hollow PVC Boards

Lightweight and Durable: Hollow PVC boards offer a much higher strength-to-weight ratio, making them easy to handle and install without compromising their structural integrity. They are highly durable against various adversities and can survive for long in environments with extreme humidity or temperature variations.

Moisture and Corrosion Resistance: These materials offer the best resistance to water and moisture, making them most suitable for operations in wet or humid environments. They do not corrode or warp with time, unlike the traditional materials of wood or metal.

Thermal and Chemical Stability: Due to their lower thermal conductivity, hollow PVC boards maintain stable temperatures and can also be used for insulation. Their chemical resistance allows them to resist substances like acids, bases, and other compounds frequently used in industrial situations.

Eco-Friendly and Sustainable: Hollow PVC boards can be recycled, contributing to waste reduction, and thereby fitting into the philosophy of sustainable construction. Their manufacturers may utilize a certain percentage share of recycled content in their manufacturing processes as well, which further reduces their overall environmental footprint.

Cost-Effective Solution: Due to their durability, they require much less maintenance than others and are also less prone to damage. So hollow PVC boards are really a cost-effective alternative to any other conventional materials. Economically, hollow PVC boards are suitable for applications that span various industrial sectors.

Customizable and Versatile: Using 21st-century technology with advanced extrusion processes, hollow PVC boards can be produced in various sizes, thicknesses, and finishes, ensuring they align with any design specifications. In terms of versatility, this, of course, makes them the natural choice for applications such as wall cladding, furniture, billboards, signage, etc.

Applications in Architecture and Design

Hollow PVC panels have found favor among present-day architects and interior design experts for their functional and aesthetic versatility. They are lightweight yet uniquely sturdy, making them suitable for applications where a good measure of performance and looks is needed in ceiling panels, partition walls, and decorative cladding. Furthermore, as they resist moisture and environmental degradation, they are ideal in areas of high humidity, such as bathrooms and kitchens.

Beyond function, this board offers a great deal of design flexibility. Its smooth and even surface can be finished with an array of substances such as laminates or paints, thus allowing for custom designs that cater to incredible project needs. Hence, it is very suitable as applications for fine moldings or components of furniture across residential and commercial settings. The soundproofing aspect of the material further enhances its acoustic properties, thus providing additional value in offices and auditoriums.

With sustainability being increasingly addressed in design practice, hollow PVC boards resonate well with the green design agenda in being recyclable and produced in processes with low waste. Their adaptability, coupled with their technical attributes, only increases their demand in novel and sustainable architectural solutions.

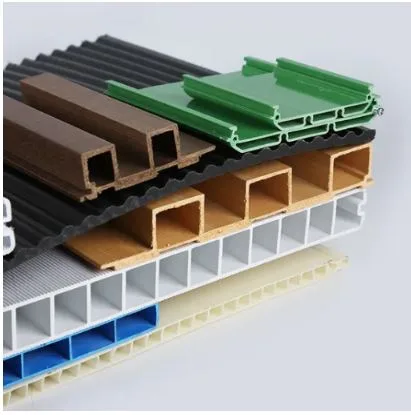

Types of Hollow PVC Products

Hollow PVC Panels vs. PVC Foam Boards

Hollow PVC panels and PVC foam boards are both versatile materials widely used in construction and design, yet they serve distinct purposes due to their specific properties and structural compositions. Hollow PVC panels are lightweight, featuring a hollow core structure that delivers excellent thermal insulation and soundproofing capabilities. These panels are particularly effective for wall cladding, ceilings, and partitions, where reduced weight and ease of installation are critical. Their water-resistant and low-maintenance characteristics make them an ideal choice for high-moisture environments, such as bathrooms and kitchens.

Among the few stands is that hollow panels are relatively lightweight and provide a strong medium for weighing down almost anything. Strength-wise, they offer significant resistance. Being extruded from a polymer foam resin, the surface offers excellent qualities for printing, painting, or laminating. These characteristics and others have made it more appealing for use in signage, display stands, and furniture applications. And actually, PVC cellular boards are much easier to machine and work with than hollow panels, whether it’s cutting, drilling, shaping, or molding to a specific design. Both very good for outdoor uses, both materials are degradable, recyclable, and rot-resistant; their differences in structural makeup, however, determine for which type of projects they are best suited. Knowing these differences is the key to making the best choice.

Exploring PP Hollow Boards

Light, forceful, and very versatile materials in innumerable industries, polypropylene-based hollow boards go by other names, such as corrugated plastic sheets. These boards are designed with a hollow-core structure to increase the strength-to-weight ratio while offering flexibility and impact resistance. Being moisture-proof and chemically inert, PP hollow boards are highly recommended for outdoor use and sites that expose them to harsh conditions, including industrial packaging, agriculture, and signage.

A major advantage of PP hollow boards lies in their customizability. They can be manufactured to meet particular requirements in terms of thickness, density, or size. Plus, they offer the best compatibility for die-cutting, welding, and screen printing processes, making them the right choice for branding or intricate designs. PP hollow boards being fully recyclable with a long life span, help reduce waste. With such advantages, PP hollow boards become a cheaper and more sustainable option for temporary or long-lasting use in different sectors.

Understanding Different Geographical Locations

Sheet PVC, or polyvinyl chloride, is accessed in many formulations and grades that are made to meet certain operational requirements in various industries. The chief types usually differ between a rigid variety of PVC (unplasticized PVC or uPVC) and a flexible variety of PVC. Rigid PVC is known for its high impact resistance, good dimensional stability, and superior chemical resistance, making it suitable for use in construction, signage, and machinery components in industry. It has the least thermal conductivity, making it highly effective for insulation purposes.

In contrast, flexible PVC is extruded with plasticizers to make it softer and more flexible. This version, due especially to its flexibility and durability, finds tremendous use in applications such as cable insulation, tubing for medical purposes, and protective covering. Both are inherently resistant to fire, abrasion, and moisture, making them excellent candidates for use in a demanding environment. One cannot overlook that these qualities necessitate selecting a PVC that satisfactorily meets the mechanical, thermal, and chemical requirements of the application under consideration.

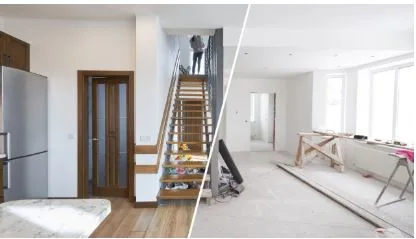

Innovative Uses of Hollow PVC in Interior Decoration

Hollow Interior Decoration Cladding

Owing to their structural advantages, ease of installation, and pleasing looks, hollow interior decoration claddings are becoming increasingly popular. Since they are light, they place a lesser load on the walls and ceilings and have lots of advantages in modern construction projects. Usually made of PVC, this type of cladding finish repels moisture and should not allow mold growth, thus resisting any environment-based deterioration, with benefits in durability and maintenance. The hollow structure also features insulation qualities, as well as thermal and acoustic advantages for residential and commercial interiors.

Since hollow cladding panels consist of various modules, installation can be completed swiftly and with ease, thus reducing labor costs and construction time. Advancements in manufacturing techniques offer a wide range of patterns, textures, and colors for customized aesthetics, aligning with the creative intent of designers while maintaining functionality. Besides being a technological upgrade, hollow cladding is also a sustainable choice—adaptive varieties use recyclable materials that contribute to building green. Thus, with their functional efficacy and versatile aesthetics, hollow interior decor claddings have come to form the backbone of contemporary architecture.

Wooden Grain Hollow Designs

Wood grain hollow design aims to replicate the natural bed of wood, conferring warmth and organic aesthetics on something that would otherwise require considerably high maintenance compared to solid wood. These designs employ cutting-edge-oriented machining processes that allow a high degree of precision in reproducing the pattern of grains, besides the resistance against adverse weathering. From moisture ingress and UV rays to temperature fluctuations, they would withstand all the environmental hazards thrown at them. Available in different finishes and textures, the products can be combined into any architectural style building, be it classic or modern. Moreover, many wooden grain hollow claddings are made of composites, which means that wood fibers and polymers are combined in a manner that ensures greater stability, lower warp factor, and higher lifespan. This also makes these guys a viable product for sustainable construction, as they use recycled content in many areas and therefore help lessen material waste.

Applications: Waterproof and Fireproof

With advancements in materials technology, cladding solutions have evolved to successfully combine fireproof and waterproof properties, meeting the demanding requirements of contemporary constructions. The Fire-resistant Cladding is engineered from modern compounds, such as magnesium oxide or aluminum hydroxide, that can withstand very high temperatures and prevent the spread of fire. Often, these substances are subjected to very rigid tests to satisfy safety standards due to international building codes.

Below the waterproof cladding, the idea is to keep water from entering the structure, especially sometimes from a soaking rainwater field. Water encourages structural degradation and mold growth. On the upside, if treated properly, waterproof cladding systems are built from water-repellent coats, interlocking mechanisms, and solid sealants to withstand harsh weather conditions for a long time. Combining fire-resistance with waterproof features enables one to maintain high safety and integrity, which in turn requires very low upkeep. This presents a good value for applications in residential, commercial, and industrial projects alike.

Durability and Maintenance of Hollow PVC Boards

UV Resistance and Longevity

Hollow PVC boards are machined for utmost UV resistance and longevity. The latest trend is the engineering of the PVC material itself to incorporate molecules of UV-stabilizers and other modern additives that protect from UV radiation. This means they cannot stain, crack, or degrade on prolonged exposure to sunlight. Independent testing has further supported the claim by confirming that a good hollow PVC board maintains its structural strength and retains its good looks for at least 15 years, making it an ideal choice for outdoor use. The boards increase longevity against moisture and microbial attacks, depending on the prevailing environment, making them a sturdy yet easy-care solution for various construction and design applications.

Cleaning and Maintenance Tips

Proper cleaning and maintenance are vital for any hollow PVC boards to stay in the way of longevity and good looks. Mix the mild detergent in warm water, then wipe it using a non-abrasive sponge. If there are any stubborn stains, then scrub gently for short periods only with a soft-bristle brush while applying very little pressure. After each cleaning, rinse with plenty of clean water to take away every trace of soap, which may otherwise cause discoloration as time goes by.

For periodic maintenance, check for any debris caught in seams or joints, as this may promote water retention and reduce performance. Wipe with a soft, dry cloth or blow away any dirt or dust from these areas using compressed air. Also, ensure that the boards never come into contact with nasty chemicals like solvents or strong acids because before you know it, their protective coating may be gone. Following these procedures will be enough to keep hollow PVC boards sturdy and looking in shape, irrespective of what conditions they are exposed to.

Rigid PVC and Other Materials

The combination of durability, cost-efficiency, and versatility is what makes rigid PVC stand out among other materials, such as wood, aluminum, fiberglass, and so on. It is resistant to moisture-based elements, making it perfect for environments with high humidity or frequent splashes with water. Whereas wood can warp, rot, and be infested by insects with little maintenance, rigid PVC, in contrast, requires very little repair and simply performs for longer.

In thermal insulation, rigid PVC offers better insulation than aluminum, where the thermal conductivity is lower, saving energy in applications. Unlike aluminum, which corrodes near the sea, PVC does not corrode and is distinguished as a suitable material for such installations. Aluminum, however, is known to have much higher tensile strength than rigid PVC, which is strong enough for structural use and is lighter.

Because of its durability properties, fiberglass is yet another common material with some corrosion resistance and little damage from water. However, the price tends to be high for fiberglass items and may require a higher level of technological process. Conversely, rigid PVC is more flexible and workable during its installation, thereby facilitating handling and saving some labor costs.

Being moisture-proof, thermal insulator, less maintenance, and cost-effective, rigid PVC is, thus, a serious contender for use in numerous industries, endorsing its use in both structural and aesthetic applications.

Customization and Design Flexibility

Customizing Hollow PVC Panels for Unique Projects

Customizing hollow PVC panels means grasping their inherent versatility, which allows for complex parametric applications. In essence, these panels must be manufactured in all sizes, thicknesses, and finishes demanded by the project. For example, a manufacturer may custom-order panel sizes to meet odd architectural design criteria or spaces. Surface finishes can be further treated to provide a specific texture or appearance, depending on the desired design intent, thereby enhancing design freedom. This is very useful in interior designs or retail installations, where aesthetics play an essential role.

In my assessment, the examination of advanced printing and coating technologies, which enable hollow PVC panels to mimic wood, stone, or other expensive materials at a fraction of the cost and weight, is considered. If a project sponsors branding or any form of personalization, UV digital printing will apply the custom graphics, logos, or patterns directly onto the panels without any negative impact on their durability. The fusion of functionality and decoration grants hollow PVC panels the flexibility that can be applied to any usage, be it a trade show display or decorative wall cladding for a commercial space.

Function reductions fall into another customization category. Panels can be designed with such desired qualities offered by the project, such as fire resistance, UV protection, antibacterial coatings, etc. This way, hollow PVC panels maintain their aesthetic functionality while meeting difficult safety and durability criteria in a given environment. By utilizing such customizations well, I ensure that hollow PVC panels fit any particular project’s working and creative parameters.

Combining WPC wall paneling with PVC

Combining WPC (Wood Plastic Composite) wall panels with PVC involves merging their unique properties to yield enhanced functionality and superior performance. WPC has some outstanding features, which likely make one believe that the panels would be immensely durable, resistant to moisture, and require minimal maintenance due to their composite structure of wood fibers and thermoplastics. In contrast, PVC is a bit more flexible and lighter in weight while being resistant to environmental hazards, such as UV radiation, water, and chemicals. The combination of these materials would enable me to synthesize solutions that maximize their strengths to answer the practical and aesthetic demands of the projects.

WPC-PVC integration owes its technical essence to several aspects that ensure compatibility in their design profiles and installation methods. It is common for WPC wall panels to adopt interlocking systems; hence, the design for interlocking shall become very picky to accomplish flawless integration with hollow PVC panels in the final product, with good engineering along the way to maintain their mutual strength. Adhesives, fasteners, or mechanical locking systems can be used to maintain connections. Of course, consideration should also be given to thermal expansion and contraction properties of the two materials to avoid warping or being misaligned through the course of time.

Using WPC and PVC to their fullest complementary attributes actually enables us to engineer hybrid solutions that are partly design aesthetic and fully functional! This integration favors much the spatial requirements of resistance to high humidity, for example, bathrooms and kitchens, or resistance to temperature fluctuation as in exterior cladding applications. Furthermore, designing with surface finishes or colors offered by PVC and free textures provided by WPC will create innovative design solutions able to satisfy modern architecture demands, flawless in the long term. Making both materials in perfect marriage for sustainable and versatile wall panel solutions is the premise of this approach.

Designing with Laminated PVC Options

Whenever I work with laminated PVC options, I aim to highlight the adaptability, durability, and aesthetic versatility of the material to meet various requirements. Laminated PVC panels are beautiful because they can impersonate distinguished materials such as wood, stone, or metal while performing better under harsh conditions. These panels are both light and heavy-duty, resisting moisture and high levels of wear and tear, making them fantastic choices for bathrooms, kitchens, and commercial interiors. To top it all off, the lamination further enhances the beauty of these sheets, boasting a smooth surface that is scratch, stain, and UV resistant-aesthetic value for days!

I also ensure that form choices for laminated PVC are congruent with the functional and design requisites of the project. These recent advances in lamination technology allow for the entry of textures, matte or glossy finishes, or even antimicrobial properties into a single PVC surface. All these customizations add a significant visual impact while also providing usability in areas where hygiene, cleanliness, or top-level sanitation are the focal points, such as health centers or food processing facilities. Besides this, now laminates of PVC are touted as green products, with recyclable ingredients and low-VOC alternatives leading the way to greener methods of construction.

Such blueprints allow me to balance the tradeoff between form and function using laminated PVC. Installation methods are straightforward, while maintenance is essential to reduce project timelines and ongoing maintenance costs. Staying informed about modern refinements in laminated PVC material enables one to achieve innovative solutions in design projects that are simply beautiful, extremely long-lasting, eco-friendly, and highly efficient.

Frequently Asked Questions (FAQs)

What is a hollow PVC board, and how is it used in construction?

A hollow PVC board, also known as a PVC panel, is a very light and long-lasting construction material made of polyvinyl chloride. It is extensively used in multiple sectors, including wall cladding, ceiling panels, and interior decoration. One of the characteristics of the perfect insulation is its hollow design, which is very easy to handle and maintain. It is also a property of the hollow PVC board that the material is not affected by water, making it the right choice for areas in very humid climates. Thus, due to its different usages, it has a wide range of applications and is versatile in these applications. In these various fields, it has become an in-demand material in the construction industry.

Are hollow PVC panels waterproof and suitable for outdoor use?

Absolutely, you can customize the composition of the PVC boards according to your needs. For instance, you can have your own color, texture, and assay laminate sheets on the board that are going to be exposed to sunlight; so they look good and remain durable too. Also, good-quality available PVC boards will be used where it is not necessary to have materials resistant to exterior conditions.

In what ways are hollow PVC boards superior to conventional wood materials?

There are multiple benefits of utilizing hollow PVC panels instead of classic wood products, such as higher durability and resistance to water. Wood can get bent, decay, or even get infected by insects, whereas PVC sheets are fabricated for harsh environmental conditions. Additionally, PVC boards do not require high levels of conservation, which makes them the best choice for both homeowners and builders. Moreover, PVC boards are usually much lighter than wood; thus, their installation is much simpler and quicker. Their eco-friendly manufacturing procedures only add to their attractiveness as a sustainable construction material.

What reasons do hollow PVC boards have for being unmatched in interior decoration?

The use of hollow PVC boards in interior decoration has many advantages, such as being very easy to install and offering a wide range of styles. The panels can be put up quickly, either on walls or ceilings, which is why contractors like them for their time efficiency. Besides, a variety of styles is available, from the latest translucent ones to the classic wood grain hollow designs. This makes it possible to have a creative décor in any case. The insulating properties of the product work in favor of keeping an indoor environment comfortable, while at the same time the product is durable, which means beautiful for a long time to come. The other major advantage of PVC’s lightness is that less support is needed compared to heavy materials.

How can I get the best performance out of hollow PVC panels for the longest time?

It is very easy to protect and keep up PVC hollow core board with little to no input. Typically, a mixture of mild soap and water, if applied to the surface, will work well for cleaning. The use of rough cleaners or tools should be avoided as they can wear off the gloss of the surface. Frequent wiping with a damp cloth helps to avoid dust accumulation and preserve your panels’ good appearance. Moreover, being stain and moisture-resistant, PVC doesn’t allow the development of mold or mildew and is, therefore, the most suitable option for the kitchen and bathroom. If you provide appropriate ventilation, you will achieve an even better situation in terms of the durability and appearance of your PVC wall panels.