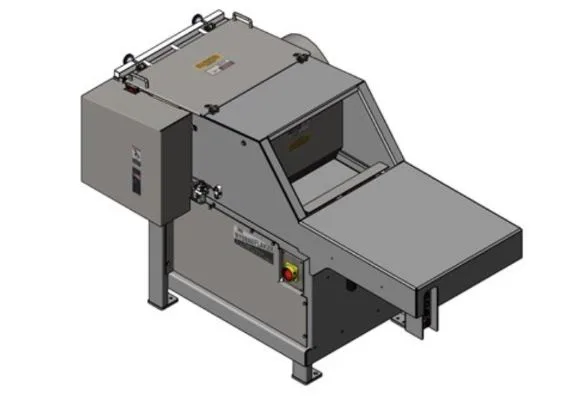

Food Processing Equipment: Optimizing Efficiency and Quality in the Industry

The food processing industry is a cornerstone of global commerce, supplying essential products to consumers while maintaining high standards of safety, efficiency, and quality. At the heart of this industry lies food processing equipment, which enables manufacturers to streamline operations, improve product consistency, and meet regulatory requirements. Choosing the right equipment is crucial for operational success, cost management, and maintaining a competitive edge. Partnering with a trusted provider like GenMac ensures access to advanced machinery, expert guidance, and reliable support tailored to the unique demands of the food processing sector. As a field expert, I can confirm that investing in the right equipment is a strategic move that directly impacts productivity, quality, and profitability.

Understanding Food Processing Equipment

Food processing equipment encompasses a wide array of machinery designed to handle various stages of food production, including preparation, cooking, mixing, packaging, and storage. The right equipment increases production speed, reduces labor costs, and ensures that products meet consistent standards of taste, texture, and appearance.

GenMac, as a trusted provider, offers a comprehensive selection of machinery suited for different types of food processing operations. Their expertise ensures that clients receive equipment tailored to their production capacity, product specifications, and regulatory compliance needs. By combining quality machinery with knowledgeable support, GenMac helps food manufacturers achieve efficiency and maintain high standards.

Enhancing Operational Efficiency

Efficiency is a key driver in the food processing industry. Automated and specialized equipment reduces manual labor, minimizes downtime, and streamlines production processes. From automated mixing systems to high-speed packaging machines, each piece of equipment plays a role in accelerating production without sacrificing quality.

GenMac works closely with manufacturers to identify areas where food processing equipment can optimize operations. Their solutions focus on minimizing waste, improving workflow, and integrating machinery that complements existing processes. By enhancing operational efficiency, manufacturers can increase output, reduce production costs, and meet market demands more effectively.

Maintaining Quality and Consistency

Consistency is critical in food production. Consumers expect products to taste the same, look appealing, and meet safety standards every time. Food processing equipment ensures precise measurements, uniform cooking, and standardized packaging, which helps maintain product quality at scale.

GenMac provides equipment designed with precision and reliability in mind. Their machinery allows operators to control variables such as temperature, mixing speed, and portion sizes, ensuring that every batch meets exacting standards. By maintaining consistency, manufacturers can enhance brand reputation, satisfy customers, and comply with strict industry regulations.

Compliance with Food Safety Regulations

The food industry is highly regulated, with strict requirements for hygiene, traceability, and product safety. Food processing equipment plays a vital role in achieving compliance, from stainless steel construction for easy cleaning to automated systems that reduce contamination risks.

GenMac ensures that all equipment meets industry standards and regulatory guidelines. Their team assists manufacturers in selecting machinery that supports proper sanitation, monitoring, and quality control measures. Compliance-focused equipment not only protects consumers but also shields businesses from potential legal and financial risks.

Customization and Scalability

Every food production facility has unique needs, depending on product type, production volume, and workflow. Customizable and scalable equipment allows manufacturers to adapt their operations as demand grows or product lines expand.

GenMac specializes in providing tailored solutions that match the specific requirements of each facility. Whether integrating new machinery into an existing production line or designing a complete system from the ground up, they ensure that equipment is flexible, efficient, and future-proof. Scalability allows manufacturers to invest confidently, knowing that their equipment can grow with their business.

Minimizing Maintenance and Maximizing Reliability

Reliable equipment minimizes downtime and production interruptions, which are critical for profitability and efficiency. Regular maintenance, easy access to spare parts, and robust construction contribute to long-lasting performance and reduced operational costs.

GenMac offers machinery that is designed for durability and ease of maintenance. Their team provides guidance on preventive maintenance schedules, troubleshooting, and system optimization. By minimizing maintenance challenges and ensuring consistent reliability, manufacturers can maintain smooth operations and maximize return on investment.

Conclusion

Food processing equipment is essential for efficiency, quality, compliance, and long-term success in the food industry. By selecting advanced machinery and working with a trusted provider like GenMac, manufacturers can optimize production processes, maintain consistency, and meet both regulatory and consumer expectations. From operational efficiency to equipment reliability and scalability, the right tools support growth, profitability, and innovation. Partnering with experts ensures that every piece of equipment enhances productivity while delivering superior results, allowing food producers to remain competitive in a dynamic and demanding market.