Hotel Doors: Balancing Fire Safety and Sound Insulation in 2026

Hotel doors face a challenge that most building parts don’t have. Guests slam them, lean on them, kick them with luggage, and complain about noise long before anyone thinks about fire safety. But when a fire happens, these same doors must work perfectly. This double job of keeping rooms quiet every day while staying ready for emergencies is why picking the right hotel door is so important.

Why Hotel Doors Are Different From Other Buildings

Hotel doors sit right where guest comfort meets safety rules. Unlike most building parts, doors can’t quietly fail. Guests notice noise problems right away and tell management about it.

This is why hotel developers work closely with experienced suppliers, including many Chinese wooden acoustic fire door manufacturer partners who understand both the safety requirements and the daily performance needs that hotel doors must meet.

Hotels Run on Guest Experience, Not Just Specs

A hotel guestroom door opens and closes dozens of times each day. Housekeeping enters. Maintenance staff checks things. Guests go in and out repeatedly.

Over months and years, hinges get loose. Seals wear down. Door frames shift slightly. A door might pass all tests on paper but still become a noise problem after regular use.

This is why chasing higher lab numbers for sound blocking often doesn’t work. What really matters is how well the door blocks sound after being used for months or years. Small gaps and shifts add up over time.

Fire Safety Cannot Fail

Fire safety works differently. A door might never face a real fire during its entire life. But if that moment comes, the door must work perfectly. There’s no room for even small problems.

This creates tension. Hotel doors must handle daily wear without damaging a system that needs to stay perfect forever.

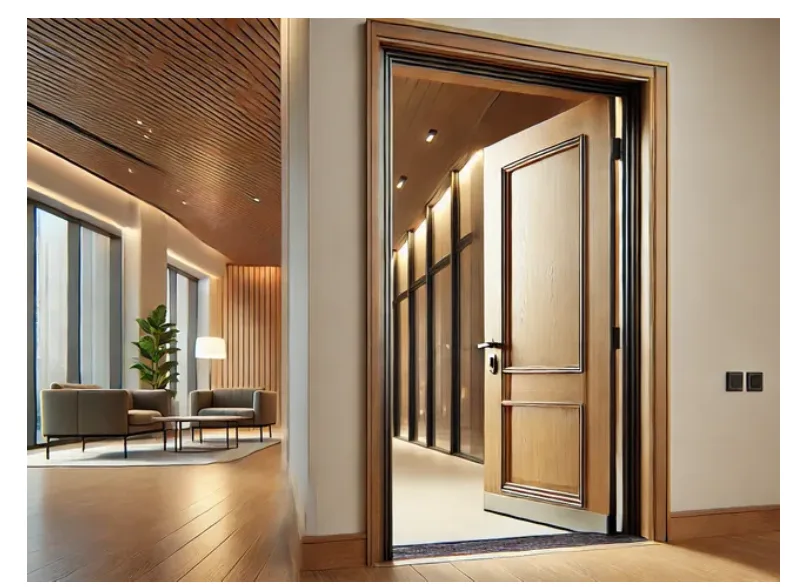

Why Wooden Doors Still Win in Hotels

Despite predictions that they would disappear, wooden doors remain the top choice for hotel rooms. This isn’t just about looks or tradition.

How Wood Handles Vibration and Sound

Wood behaves differently than thin metal when vibrations happen. Solid wooden cores or composite wood naturally dampens sound. This reduces the middle and high sounds that travel from hallways into rooms.

This doesn’t automatically make wooden doors quiet. But it gives them a more forgiving starting point when seals and frames aren’t perfect. Lighter materials struggle to do this.

Think about a hotel in Shanghai. They tried metal doors to save money. Guest complaints about hallway noise tripled within six months. They switched back to wooden acoustic fire doors and complaints dropped to normal levels.

Guests Judge Doors by How They Look and Feel

A door that looks solid makes guests expect it to feel quiet and secure. When appearance matches performance, complaints go down. When they don’t match, even okay sound blocking feels inadequate to guests.

Wooden doors naturally meet these expectations in hotel settings.

Where Hotels Get Sound Insulation Wrong

Most sound problems blamed on doors don’t come from the door itself. They come from small mistakes made in other parts of the door assembly.

Lab Ratings vs Real Installation

Lab ratings like STC (Sound Transmission Class) or Rw often get treated as promises. In hotels, they’re not. Once installed, performance depends mainly on what’s around the edges.

A high rated door with a poorly chosen frame or inconsistent gaps will perform worse than a lower rated door installed carefully. This explains why hotels often replace doors that tested well but never delivered quiet rooms. The rating didn’t account for how the door would age with use.

Hardware, Frames, and Seals Make or Break Sound Blocking

Hardware choices affect sound blocking. Latches that don’t close firmly allow tiny gaps. Door closers set too strong wear out seals faster. Frames without enough stiffness send vibrations into walls.

These effects get worse over time. Good hotel sound insulation depends less on any single part than on how well the whole system holds its shape after being used repeatedly.

The Truth About Fire Rated Wooden Doors

Many people still believe wooden doors compromise fire safety. In modern hotel construction, this belief is outdated and wrong.

Fire Resistance Is About the Whole System

Fire rated wooden doors work as a complete assembly. The door leaf, core materials, frame, seals, glass (if any), and hardware all contribute to performance. When designed and tested properly, these assemblies meet the same safety rules as alternatives, including 30, 60, or 90 minute fire resistance ratings.

Fire rated wooden doors aren’t “treated wood pretending to be safe.” They’re engineered systems whose behavior under heat is understood and reliable.

Fire Rating and Sound Control Can Work Together

Higher fire ratings don’t hurt sound blocking potential. Sometimes, increased core density and thickness help both goals. Problems only happen when fire requirements get met through surface fixes that ignore long term strength, such as relying too much on coatings without structural support.

Why Manufacturing Quality Decides Success or Failure

At the project level, the difference between success and frustration often isn’t in the design. It’s in how consistently things get made.

Consistency Beats Peak Performance

One perfect sample door proves very little. Hotel projects need hundreds or thousands of doors that all behave the same way. Wood veneer must stay stable. Frame measurements must stay accurate. Hardware preparation must stay consistent across batches.

When quality drifts, installation teams fix problems in the field. This often hurts sound performance. Experienced suppliers understand that consistency matters more than chasing extreme numbers.

Why YK Fire Door and Experienced Manufacturers Stand Out

Over the past ten years, many hotel projects have turned to experienced partners like YK Fire Door and other Chinese wooden acoustic fire door manufacturers. This isn’t just about cost.

It’s about accumulated project discipline. Repeated exposure to international hotel standards, custom sizes, and large scale delivery schedules has shaped production methods that focus on doing things the same way every time.

When manufacturing quality stays steady, design plans survive installation. Both sound comfort and fire safety stay intact over time.

Design for Balance, Not Extremes

The most reliable hotel door strategies avoid pushing too far in any direction. Over focusing on fire resistance without thinking about daily use creates stiff doors that break down quickly. Over focusing on sound without structural discipline creates doors that feel quiet at first but fail gradually.

Successful projects understand that some compromises are built into the structure. Many failures can be avoided. Coordination between design, manufacturing, and installation determines which category your project falls into.

A well designed hotel door succeeds not by maxing out fire ratings or sound numbers alone. It succeeds by maintaining dependable balance under daily use, where quiet comfort and safety coexist without drawing attention to themselves.

FAQs

Can fire rated doors also block sound effectively?

Yes, fire rated doors can provide excellent sound insulation when properly designed with dense cores and quality seals.

Why do wooden doors work better than metal for hotel rooms?

Wooden doors naturally dampen vibrations and meet guest expectations for a solid, quiet feel better than thin metal alternatives.

What makes hotel door quality consistent across large projects?

Experienced manufacturers with hotel project discipline maintain consistent tolerances, material quality, and hardware preparation across hundreds or thousands of units.