How Do Modern Construction Materials Improve Structural Durability and Performance?

The building sector is in the process of changing dramatically with the advent of new materials and technologies to make the buildings durable, safe and energy efficient. Sophisticated infrastructure projects require high performance components that are capable of withstanding environmental issues as well as being more reliable in the long run.

Among these innovations, MS Hybrid sealants and anodized aluminum panels are playing a pivotal role in redefining architectural standards. These two products are different in nature but they overlap in a number of construction applications to offer enhanced solutions to structural performance.

Knowing their properties, uses and combined benefits, can provide a glimpse of how contemporary materials are changing the future of construction.

The Growing Role of MS Hybrid Sealant in Construction:

MS Hybrid sealants have become one of the most versatile bonding and sealing solutions in modern construction. These sealants are the best of both worlds, silicone and polyurethane technologies to provide the best of all worlds, exceptional adhesion, flexibility, and durability. Compared to traditional sealants, MS Hybrid formulations do not contain isocyanates and solvents, which makes them safer in residential, commercial, and industrial applications.

One of the key advantages of MS Hybrid sealant is its ability to adhere to a wide range of substrates, including metals, glass, plastics, and composite panels. This is what makes it very useful in projects where several materials are to be joined together without undermining the structural strength.

The sealant is also very resistant to environmental conditions like UV radiation, moisture, and changes in temperature which also guarantee longevity of the sealant in the harsh outdoor environment.

In construction projects, MS Hybrid sealants are widely used for applications such as façade sealing, joint filling, structural bonding, and waterproofing. They stop the infiltration of air and water and make buildings more energy efficient and durable. The elasticity of their structures over time makes structures adapt to thermal expansion and contraction without jeopardizing stability.

As architectural designs become more complex, the versatility and strength of MS Hybrid sealants make them a preferred choice among builders, engineers, and designers.

Anodized Aluminum Panels and Their Architectural Advantages:

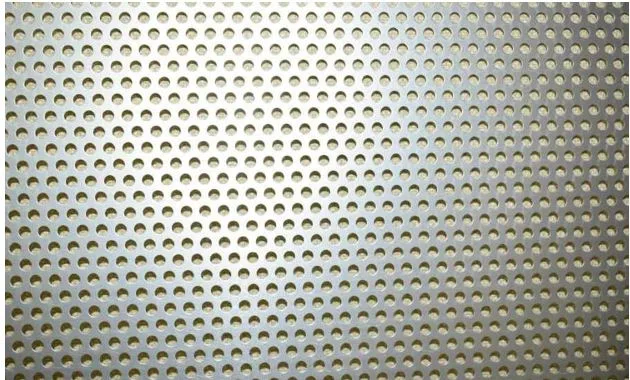

Anodized aluminum panels have emerged as a leading material for modern façades and cladding systems. Anodization is an electrochemical process which enhances the natural oxide film on aluminum and makes it more resistant to corrosion, wear and fading. This produces panels with a long-lasting protective finish that does not lose its aesthetic value in decades.

Architects and builders increasingly prefer anodized aluminum panels because of their lightweight structure, structural stability, and exceptional surface hardness. The panels can be applied to exterior cladding, roofing, column covers, ceilings and interior design applications and can be applied to achieve a wide range of architectural styles. The panels can be had in various finishes and colours allowing the designers to address both functional and aesthetic needs without compromising.

Another significant advantage of anodized aluminum panels lies in their durability under extreme weather conditions. The reinforced surface layer offers superb protection against UV rays, moisture, and industrial pollutants and can be utilized in a long-term outdoor installation. Also, the surface can be anodized, which makes it resistant to scratches and stains, which minimizes maintenance cost, and maintains its visual quality.

With sustainable construction practices gaining popularity, these panels are appreciated because of their recyclability and energy-efficient characteristics, as they fit well with the current environmental requirements without compromising the performance.

Synergy Between MS Hybrid Sealants and Anodized Aluminum Panels:

While MS Hybrid sealants and anodized aluminum panels serve different primary purposes, their integration within construction projects creates a complementary relationship that enhances overall structural performance. The sealing process is very important when fixing aluminum cladding systems to prevent water penetration, air movement and the degradation of the environment.

MS Hybrid sealants provide the bonding strength and flexibility required for securing anodized aluminum panels while maintaining their visual appearance.

Large-scale aluminum panel installations in particular are commonly subjected to large thermal variations. Expansion and contraction due to the change of temperature can put strain on joints and connections and may pose a threat to structural stability. MS Hybrid sealants address this challenge by retaining elasticity, allowing joints to accommodate dimensional movement without cracking or detaching.

This makes the panels stay firmly mounted over a long time without losing alignment and aesthetic look.

The Future Trends in High-Performance Construction Materials:

The need to have new construction materials is increasing by the day due to the complexity of architectural design and an increase in performance requirements. Future developments in MS Hybrid sealants and anodized aluminum panels are expected to focus on enhancing material properties, improving sustainability, and integrating smart technologies.

For MS Hybrid sealants, ongoing research aims to create formulations with increased resistance to extreme environmental conditions while improving bonding strength. New manufacturing processes are allowing sealants of greater elasticity and adhesion to non-traditional materials, extending their use to a variety of construction areas. These innovations will also aid in solving some of the new challenges that are being posed by energy efficiency, airtightness, and moisture management in modern building envelopes.

In the case of anodized aluminum panels, technological advancements are expected to drive further improvements in surface treatments and finishes. New anodization processes can result in panels with greater levels of self-cleaning, reflectivity to create energy efficient facades and expanded color customization. Also, manufacturers are experimenting with hybrid panel designs where anodized aluminum is used with composite cores to create lighter, but stronger materials to use in large-scale architectural work.

Conclusion:

Advances in construction materials are rewriting the capabilities of architecture, and increasing the sustainability and performance of contemporary structures. Products like MS Hybrid sealants and anodized aluminum panels exemplify how technological innovation is shaping the future of construction. Sealants provide secure bonding, excellent weatherproofing, and flexibility, whereas the anodized panels offer unmatched durability, corrosion resistance, and aesthetics.