How Do Pyrolysis Machines and Heat-Resistant Car Films Showcase Practical Innovation?

Have you ever wondered how some technologies operate without making noise and transforming industries and everyday life? Others include those which are concerned with large-scale changes, and others with individual comfort and safety. Though they may seem unrelated at first glance, the pyrolysis machine and heat-resistant car film both demonstrate how practical innovation can improve efficiency, sustainability, and convenience.

Understanding their functions and significance reveals why these two solutions matter more than they first appear.

The Role of Pyrolysis Machines in Industrial Transformation:

Industrial processes are under increasing pressure to manage waste efficiently and also obtain value out of the discarded materials. The pyrolysis machine represents one such advancement, designed to convert waste into usable outputs through thermal decomposition.

In its simplest form, pyrolysis is the heating of organic materials without the presence of oxygen. It does not release flames like the combustion, but rather splits up materials into smaller molecules. The products that end up are usually liquid fuel, gas and char, which have potential uses.

For example, waste plastics processed in a pyrolysis machine can be transformed into fuel oil, which serves as an energy source. On the same note, biochar could be obtained through biomass that may be agro-residues thus enhancing soil fertility. Tires that are normally hard to dispose of safely can even be turned into oil and carbon black, which will lessen the environmental burdens.

This technology is important because it is dual purpose. It lessens the amount of waste and at the same time, it generates resourceful resources. Industries gain through reduced disposal expenses and the establishment of alternative sources of revenue and municipalities get solutions to the growing waste problems. Pyrolysis is an alternative method of waste management that is increasingly becoming a topic of interest with increasing global demand on sustainable practices.

Advancements in Heat-Resistant Car Films:

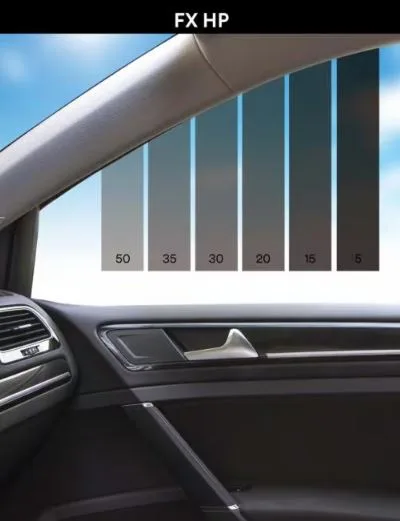

On a much smaller scale but equally impactful for daily life, the heat-resistant car film enhances comfort and safety for drivers and passengers. Cars are often subjected to large amounts of sunlight which causes excessive heating of the vehicle and high levels of undesirable ultraviolet radiation. Conventional glass does not offer much protection and this usually results in the air conditioning systems being forced to exert more effort to keep people comfortable.

Heat resistant films solve this problem by creating a shield over the car windows. These films are designed with advanced layers which absorb and reflect sunlight. They can reduce the heat penetration which reduces cabin temperatures thus making the long drives more comfortable and less dependence on cooling systems is experienced.

Its advantages are not limited to thermal control. Superior heat resist films also prevent ultraviolet rays which destroy upholstery and are dangerous to health. The shatter-resistance features are added to some films, which results in a level of safety since the films reduce the number of glass fragments, in the case of accidents.

From luxury cars to commercial fleets, the need for such film is demonstrated by the increased demand on health, safety, and energy efficiency among consumers. Their use shows how material science can directly enhance the daily experiences in a way that combines convenience with a long-term value.

Similarities in the Principle of Large and Small-scale Innovations:

At first, a pyrolysis machine and heat-resistant car film may appear to have little in common. Nevertheless, they both have some significant principles of design and use. Both of them react to an urgent need, either the management of industrial waste or personal comfort, and both use scientific knowledge as a means of providing practical outcomes.

The connection is in the emphasis on efficiency. Pyrolysis machines convert otherwise wasted resources into usable products, while car films reduce energy consumption by minimizing cooling requirements. Both show how creativity can convert difficulties into opportunities, at either the industrial level or individual levels.

Reliability is another similarity. Industries depend on pyrolysis machines to operate consistently, processing tons of material without interruptions. Film owners demand films to last many years in spite of the severe environments they are subjected to. In the two, success is characterized by sustainability and longevity.

These common values emphasize the fact that the user should be trusted by the innovation, no matter its scale. Whether it is dealing with waste streams or driving conditions, good solutions are able to provide steady outcomes that are in agreement with the expectations of the user.

Applications to Real-world Legislations:

The pyrolysis machine finds application in sectors where waste accumulation poses major challenges. It is used by municipal waste facilities, tire recycling plants and agricultural processors to minimize the environmental impact. Its capability of transforming waste products into useful products makes it particularly appealing to those areas that are looking into other sources of energy.

Secondly, pyrolysis also provides industries who use it with a competitive edge by ensuring that their operations meet the current environmental laws.

The heat-resistant car film applies to daily transportation needs. Families also find it more comfortable in hot summers, and drivers are also more visible and suffer less glare. In the case of commercial fleets, less use of air conditioning translates to a saving of fuel and a decrease in operating expenses. It is also beneficial to the car dealerships to include the pre-installed films as part of the high-end packages since consumers are increasingly demanding sophisticated features.

Long-term Value and Reliability:

These solutions do not just have short-term attraction, but also long-term. For industries, investing in a pyrolysis machine ensures continuous benefits over decades. Businesses gain financial and environmental benefits by limiting their contribution to landfills and producing secondary products. Maintenance and operational efficiency plays centre stage in generating sustained value.

For car owners, installing heat-resistant car film translates into reduced wear on air conditioning systems, extended upholstery life, and consistent protection from ultraviolet rays. The reward of the investment is comfort, health and cost-saving, which is a long-term benefit to owning the vehicle.

The two innovations are based on reliability. Manufacturers of pyrolysis machines emphasize robust design and quality assurance to guarantee safe, efficient operation. The film developers are interested in multi-layers films that do not peel, bubble or fade when exposed continuously. These two industries acknowledge the fact that for user trust to be built, the industries must provide the same results annually.

Conclusion:

Innovation can be seen at both big and small scales, both large-scale industrial machinery as well as small but useful consumer products. The pyrolysis machine illustrates how science and engineering can transform waste into valuable resources. This addresses pressing challenges in sustainability and energy. The heat-resistant car film demonstrates how advanced materials improve comfort, safety, and efficiency in everyday transportation.