How Do Rockchip RK3588 and Arrayforce Membrane Contactor Technologies Reshape Modern Industries?

Usually, the corner of invention is unpredictable and sometimes leads to technological advancement. There is computing innovation in one area of expertise, and a development in the chemical engineering field. Nevertheless, an innovation can occur when such a narrow sphere meets and results in revolutionary advancements.

The combination of Rockchip RK3588 and Arrayforce membrane contactor technologies exemplifies such synergy. Both are the best innovations in their respective industries and show how digital performance can be integrated into high-tech fluid management.

This discussion explores the individual strengths of each technology and demonstrates how their integration enhances industrial operations, research, and product development across multiple sectors. So what are you waiting for? Let’s begin with our article!

What Makes Rockchip RK3588 a High-Performance Computing Solution?

The Rockchip RK3588 is recognized as one of the most advanced ARM-based processors currently available. It combines such aspects as high efficiency with processing force to provide wide applications. Aiming at creating a balanced use of power and computing capacity, it is designed to have eight cores, including both Cortex-A76 and Cortex-A55.

Another defining aspect of the Rockchip RK3588 is its compatibility with AI and machine learning workloads. Its capability to perform edge AI tasks comes in as it has built-in neural processing units and hence this makes it acceptable in real-time applications like computer vision, industrial surveillance, and autonomous systems. Its graphical processing capacities are in place as well in up-to-date multimedia operations, which are beneficial in entertainment and viewing technologies.

From industrial automation to smart device integration, Rockchip RK3588 delivers the computational foundation required to manage complex data, control systems, and intelligent devices.

How Does an Arrayforce Membrane Contactor Enhance Fluid Management?

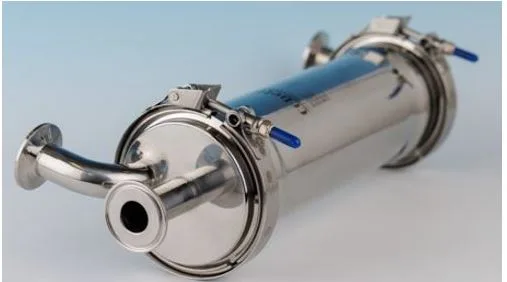

On the other side of technological innovation, the Arrayforce membrane contactor addresses a very different challenge. The issue of gas/liquid transfer in the industries is a problem when carrying out processes like degassing, carbonation, or stripping. The traditional techniques are based on bubbling or agitation and may not be efficient enough or may be subject to contamination.

The Arrayforce membrane contactor resolves these limitations by using microporous membranes to facilitate direct gas exchange without mixing phases. This makes industrial processes pure, efficient and stable. It also has uses in water treatment, pharmaceutical manufacturing, semiconductor cleaning as well as chemical processing.

By allowing precise control of gas transfer, the Arrayforce membrane contactor improves both performance and reliability, supporting industries that demand high standards of quality control and operational efficiency.

Where Do Rockchip RK3588 and Arrayforce Membrane Contactor Converge?

High-performance processors and advanced fluid management equipment at first appear to be in two different worlds. Nonetheless, digital intelligence as well as physical process optimization is becoming more and more essential in the modern industries. Rockchip RK3588 and arrayforce membrane contactor converge can combine in areas including the following:

- Biotechnology: Research labs using an Arrayforce membrane contactor for sterile gas transfer may use Rockchip RK3588-powered devices for real-time monitoring, data analysis, as well as automated control.

- Pharmaceuticals: Helps in achieving precision in drug manufacturing. .

- Industrial IoT systems: Factories adopting membrane-based gas management also integrate smart monitoring systems powered by advanced processors for efficiency and predictive maintenance.

Together, these technologies highlight the growing relationship between digital computation and industrial engineering.

Market Trends Shaping Rockchip RK3588 and Arrayforce Membrane Contactor Applications

The dynamics that are manifested globally in the marketplace indicate the role of the two innovations as pertaining to the industrial transitions as a whole.

For the Rockchip RK3588, demand is driven by rapid expansion in smart devices, AI applications, and edge computing. Businesses want to find processors that can provide analytical results in real-time and do not depend on cloud infrastructure completely. The trend represents the move towards self-autonomy in robotics, autonomous vehicles, and smart manufacturing.

Meanwhile, the Arrayforce membrane contactor benefits from stricter environmental and regulatory standards. The industries prioritize clean processes, less contamination and effectiveness in chemical processing and water management. The technology fits into the industry sustainability initiatives despite its main attraction in the precision of operation.

Collectively, these trends underline the necessity of computational intelligence of the industries in their need to incorporate a practicable process control.

Technical Aspects of Rockchip RK3588 and Arrayforce Membrane Contactor Integration:

From a technical perspective, combining Rockchip RK3588 and Arrayforce membrane contactor systems requires careful design. For example, industrial monitoring platforms may use Rockchip RK3588-based boards to run AI algorithms that can predictt membrane contactor efficiency and detect early signs of fouling or performance decline.

Such integration involves the following considerations:

- Data acquisition: Sensors attached to membrane systems collect temperature, pressure, and flow data, which the processor analyzes.

- Real-time optimization: AI algorithms help adjust flow rates or gas composition instantly.

- System reliability: The processor ensures continuous operation without failure, while the membrane maintains gas-liquid separation integrity.

The outcome is a combination of chemical precision with digital intelligence, which reduces operational risks and maximizes productivity.

Industrial Applications Benefiting from Both Technologies:

Several industries can practically leverage the synergy of Rockchip RK3588 and Arrayforce membrane contactor technologies. Some industrial applications benefiting from both technologies include the following:

- Water purification plants: Membrane contactors ensure effective degassing. While, on the other hand rockchip RK3588 helps in enabling real-time monitoring of plant performance.

- Pharmaceutical labs: It helps in maintaining sterile processes with membrane technology while relying on computational models to enhance production outcomes.

- Semiconductor industry: Membrane contactors can also assist in high-purity cleaning. While computing systems can optimize chemical usage and process parameters.

- Food and beverage: Gas transfer precision in carbonation processes combined with AI-based monitoring for consistency and safety.

Future Outlook for Rockchip RK3588 and Arrayforce Membrane Contactor Adoption:

In the future, optimisation of physical processes will combine more and more with computational systems in industries. The Rockchip RK3588, with its AI-driven performance, will continue to shape automation, robotics, and smart device ecosystems. Simultaneously, the Arrayforce membrane contactor will remain vital in sectors requiring sterile, efficient, and reliable gas-liquid interactions.

The most encouraging trend is industrial digital twins, in which a computational model is used to simulate and manage some physical system. Here, the Rockchip RK3588 manages real-time data, while the membrane contactor ensures consistent chemical performance. It is such combinations that will characterize the future of industrial efficiency.

Conclusion:

The Rockchip RK3588 and Arrayforce membrane contactor serve as representatives of digital intelligence and chemical engineering precision. The combination of them shows that different innovations can be integrated in order to revolutionize industries. Their use runs the gamut, as they are used in laboratories as well as in large-scale manufacturing, where the interplay between computation and optimization of physical processes is important.