How Speed Control Modules Enhance Efficiency in Power Tool Products

Speed control modules are essential to contemporary power tool equipment because they allow for accurate, precious, and responsive motor operation, which is crucial for safety, increase system efficiency, energy saving. Integration of these modules is now a need rather than a luxury in today’s industrial environment. This article examines which align with technologies trends and industry standards, and ways in which speed control modules improve power tool performance.

Speed Control Modules: What Are They?

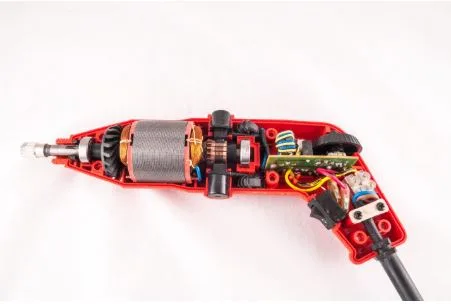

Electronic circuits known as industrial control solutions which modify the voltage or current provided to motors in order to regulate their rotational speed. Pulse Width Modulation (PWM), one of the most widely used technologies, enables effective motor speed control without compromising torque or producing excessive heat.

Speed control modules in power tool applications make sure that equipment runs at the optimal speed for the specific task, enhancing productivity and safety. Adding a speed control system to a heavy-duty grinder or cordless drill can prolong tool life and lower energy usage.

Automation’s Use of Speed Control Modules

Especially when used in power tools, speed control modules fulfill a number of crucial roles in automation systems. Here are a few of the main roles:

A Motor Controller uses a microprocessor to control power electronic devices used for motor control. Motor Controllers monitor the load on a motor and accordingly match motor torque to motor load. This is accomplished by reducing the voltage lowering current. This can provide a measure of energy efficiency improvement for motors that run under light load for a large part of the time, resulting in less heat, noise, and vibrations generated by the motor.

Servo controllers are a wide category of motor control. Common features are:

precise closed-loop position control

fast acceleration rates

precise speed control. Servo motors may be made from several motor types, the most common being:

brushed DC motor

brushless DC motors

AC servo motors

Servo controllers use position feedback to close the control loop. This is commonly implemented with position encoders, resolvers, and Hall effect sensors to measure the rotor’s position directly.

Other position feedback methods measure the back EMF in the undriven coils to infer the rotor position, or detect the Kick-Back voltage transient (spike) that is generated whenever the power to a coil is instantaneously switched off. These are therefore often called “sensorless” control methods.

A servo may be controlled using pulse-width modulation (PWM). How long the pulse remains high (typically between 1 and 2 ms) determines where the motor will try to position itself. Another control method is pulse and direction.

A stepper motor is a synchronous, brushless, high-pole-count, polyphase motor. Step Motor Controller is usually done open loop, i.e., the rotor position is assumed to follow a controlled rotating field. Because of this, precise positioning with steppers is simpler and cheaper than closed-loop controls.

Modern stepper controllers drive the motor with much higher voltages than the motor nameplate-rated voltage, and limit current through chopping. The usual setup is to have a positioning controller, known as an indexer, sending step and direction pulses to a separate higher voltage drive circuit, which is responsible for commutation and current limiting.

Stability of Feedback Loops

A feedback control loop that continuously monitor and adjust motor speed is incorporated into a well-designed speed control module. When load condition change, this loop helps keep the speed steady. For instance, a power drill’s encounter the dense material, the motor speed may slow down. To ensure steady operation, a control module will detect the speed decrease and regulate the power output appropriately.

Minimization of Operational Errors

One immediate advantage of speed control modules is the ability to reduce operational errors. These modules ensure that tools operate at their best speeds by dynamically modifying the power sent to the motor in response to real-time data. This capability is crucial important for precise operations, where even slight variations in speed can affect the quality of final product.

Using Nonlinear Current Regulation to Prevent Overspeed

Motor overspeed can result in accelerated wear and tear as well as potential safety risks. Nonlinear current limiting, a method used in modern speed control modules, keeps motors from operating beyond the safe speed and current limits. This control is to improves tool safety and extend the motor’s operation lifespan by reducing mechanical and electrical stress

Load matching and energy efficiency

Advanced speed control modules’ capacity to conserve energy by adjusting power output to the real load is one of its best qualities. These modules regulate the motor’s energy usage based on workload rather than operating it at full speed all the time, which lowers energy costs and has a less environmental impact.

Advantages of Power Tool Products with Speed Control Modules

Speed control modules offer observable advantages when integrated into power tools. They enable users to work more quickly and precisely by ensuring smooth and efficient tool operation. Regulate motor performance through controlled speed to reduce mechanical stress, which extends component lifespan and decrease wear. By preventing over speeding and overheating, these modules also reduce the risk accidents and tool failure. Additionally, cordless tools maximize battery life by using the speed control, while corded tools reduce electricity by drawing only the power needed for the task.

Which Sectors Gain the Most from Sophisticated Speed Control Systems?

Although the power tools business makes extensive use of speed control modules, their benefits are also felt in a number of other industries:

- Industrial Manufacturing and Assembling: To maintain constant torque and speed, which is essential for product quality, high-precision tools used in automated assembly lines depend on industrial speed control solutions.

- Power tools and portable equipment : speed control modules optimize tool performance, to prevent over speed and overheating, maximize battery life.

Automobile Sector: Speed control modules enhance performance and efficiency by regulating power in a variety of motorized systems, such as assembly robots and electric seat adjustments.

- Electronics for consumers: Small-scale speed control modules are used in appliances like blenders, fans, and robotic vacuums to provide variable speed capabilities without sacrificing energy economy.

How PWM Improves the Performance of the Speed Control Module

The driving force behind contemporary speed control technology is pulse width modulation, or PWM. It regulates the “average” voltage that reaches the motor by quickly turning the power supply on and off at a high frequency. The precise control reduces heat generation, enabling more efficient power delivery as a greater portion of the input energy is converted into mechanical work. PWM also provides accurate speed regulation, making it ideal for intricate tasks. Compact design Its electronic switching allows for more integrated and smaller components.

Selecting the Best Supplier for Speed Control Modules

Selecting a speed control module source that provides quality, customization, and continuous support is essential when sourcing speed control modules . Pantene (PI) support the power tool applications, enabling seamless integration with minimal design change. For the broad system-level support and industrial-grade components, go to Pantene’s One-Stop Solution is the ideal choice.

Including Modules for Speed Control in Your Design

The following factors should be taken into account by engineers creating power tools or other automation devices when adding speed control modules. Motor Type Compatibility: Verify that the module is compatible with the particular motor type (e.g., brushed DC, BLDC, AC induction). Thermal Management: Control any heat produced during high-load operation, use enclosures or heat sinks. Configuring a feedback signal involves selecting modules that support sensors, such as encoders or Hall effect sensors. Scalability search for modular solutions for product families that can be scaled across several tools with only minor modifications and cost-effective development and production.

In conclusion

A key component of contemporary power tool design, speed control modules provide numerous benefits, including enhanced safety, energy savings, and efficiency. These modules provide consistent, accurate, and adaptable performance through the use of advanced technologies such as PWM and nonlinear current regulation. Speed control modules will continue to be a crucial element in fostering innovation as companies seek more intelligent, environmentally friendly solutions. For more information, visit Pantene’s PCBA product site to explore more about their superior industrial speed control solutions.