How to Combine a Flexo Printing Corrugated Die-Cutting Machine with Jetson Orin NX for Smarter Packaging Production?

The packaging sector has moved into a new phase in which automation, accuracy and intelligent control systems establish the new definition of efficiency. The traditional printing and die cutting processes are becoming high-tech and integrated workflows which combine mechanical force with intelligent computing.

A prime example of this fusion is the potential combination of a flexo printing corrugated die-cutting machine with advanced AI computing platforms like Jetson Orin NX. This alliance will help to make the process of packaging production more resourceful, quicker and responsive.

This discussion explores how these two seemingly different technologies can work together, the advantages of such integration, and the innovations it can inspire in the packaging sector.

Understanding the Flexo Printing Corrugated Die-Cutting Machine:

A flexo printing corrugated die-cutting machine is a cornerstone of modern packaging production. It carries out two vital functions. To begin with, it applies pliable printing plates and quick drying inks to print high quality designs on corrugated sheets. Second, it accurately perforates, cuts or creases the sheets to create packaging components.

Flexographic printing has various advantages, which include water-based ink compatibility, printing on rough surfaces, and high speed. Corrugated die-cutting guarantees that components of the packaging are in the correct shape and folding lines are crucial to the protection of the products and brand consistency.

The machines are frequently involved in constant production lines where reliability and accuracy is of the essence. Conventionally, operators have made use of mechanical adjustment and preset parameters. Nevertheless, this method may be restricted in case of fast design changes or bespoke orders. It is here that more sophisticated computing technology can prove to be a game changer.

Introducing Jetson Orin NX:

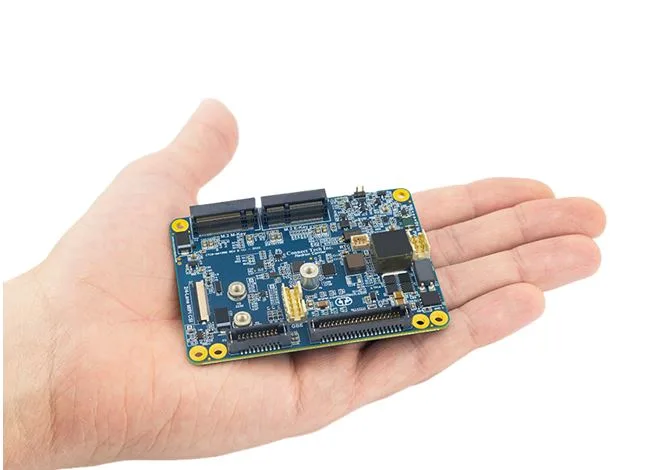

The Jetson Orin NX is a powerful AI computing platform designed by NVIDIA for embedded and edge applications. It provides powerful processing with AI functionality, making devices run complex algorithms locally, without the need of cloud computing.

Its strengths include:

- Multi-core CPU and GPU architecture for parallel processing

- High energy efficiency

- Real-time data processing and machine learning support

- Compatibility with vision-based and robotic control systems

While Jetson Orin NX is commonly used in robotics, autonomous machines, and smart surveillance, its adaptability makes it a strong candidate for industrial process automation. Combining it with a flexo printing corrugated die-cutting system could provide a pathway to real-time quality control, adaptive machine settings and predictive maintenance.

Why Combine These Technologies?

The primary goal of combining a flexo printing corrugated die-cutting machine with Jetson Orin NX is to create a smarter, more responsive production environment.

In a conventional workflow, the operators adjust the printing pressure, the viscosity of the ink and the cutting parameters manually after periodic inspection. This may cause delays and wastage of products in case mistakes are not detected. With Jetson Orin NX, the machine can monitor printing and cutting processes in real-time, detect deviations instantly, and make automated corrections.

This combination aids mass customization as well. Because packaging is shifting to smaller batch sizes with customized designs, the machine can automatically change parameters as per digital input files and this saves time in having to reconfigure the machine.

Practical Applications of Integrating Flexo Printing Machine with Jetson Orin NX:

- Real-Time Quality Inspection:

By connecting cameras and sensors to the Jetson Orin NX, the flexo printing machine can continuously monitor print alignment, color consistency, and cutting precision. The AI algorithms are able to detect small defects, e.g., ink smudges or crooked creases, before they lead to material waste.

- Automatic Parameter Adjustment::

The AI system can adjust settings dynamically rather than use pre-determined parameters. As an example, when the printing material takes up more ink than is desired, the system can automatically scale back ink application in order to preserve quality without stopping production.

- Predictive Maintenance:

Jetson Orin NX can analyze vibration data, motor performance, and temperature readings to detect early signs of wear or malfunction in the die-cutting unit. Predictive maintenance lowers downtimes and can avoid expensive breakdowns.

- Energy Optimization:

Complex algorithms are capable of controlling the use of power by regulating the speeds of working and optimizing the production schedule which leads to a reduced energy consumption rate without loss of output.

Potential Benefits for Packaging Businesses:

The integration of these two technologies offers tangible advantages:

- Reduced Waste: Real-time defect detection prevents entire batches from being scrapped.

- Higher Throughput: Automated adjustments and faster setup times boost production capacity.

- Better Consistency: AI-driven monitoring ensures every product meets strict quality standards.

- Customization at Scale: The system can handle varied designs and dimensions without manual reconfiguration.

- Lower Operational Costs: Predictive maintenance and energy optimization contribute to cost savings.

Future Prospects of Smart Packaging Production

AI computing already integrated with printing and die-cutting machines is a step in the direction of fully automatic packaging production lines. With increases in the sophistication of AI models, the machines may be able to learn how to anticipate demand trends, automatically change schedules, and even automatically re-order raw materials when they are low.

Jetson Orin NX’s scalable architecture means that it can evolve with technological trends. In the long term, the integration might not only be limited to individual machines but also to the whole production ecosystem that allows connected factories where every machine shares information with others to manage the optimal workflow.

Conclusion:

The combination of a flexo printing corrugated die-cutting machine with Jetson Orin NX represents a significant leap forward for the packaging industry. Combining mechanical accuracy and sophisticated AI-based decision-making can make the process of packaging production faster, more efficient, and more flexible to the contemporary requirements of the market.

The road to complete integration may include investment and planning, but the end-results, which include minimized waste and increased customization, make it a foresighted approach. With industries adopting smarter manufacturing systems, the industrial hardware and intelligent computing synergy will be the new face of packaging advancement.