How Top Manufacturers Stay Ahead with the High-Quality Notched Constant Ligament Stress Tester

Material testing can help industries and manufacturers understand a material’s overall properties to ensure its suitability. This blog looks into one such testing equipment, the Notched Constant Ligament Stress (UCLS) Tester, and how it benefits top manufacturers.

The UCLS test is a method to evaluate whether high-density polyethylene (HDPE) is susceptible to an accelerated environment. This post will explore how top manufacturers are using this test to stay ahead of the competition.

Understanding the Notched Constant Ligament Stress Tester

A notched constant ligament stress equipment or tester is a device that applies a constant load to a notched material specimen, which usually involves HDPE. And this pressure is used to assess its resistance to slow crack growth or stress cracking.

The tester observes whether or not the specimen fails within a specific timeframe. If it does fail, a lack of resistance is indicated, and if it remains intact, that shows durability.

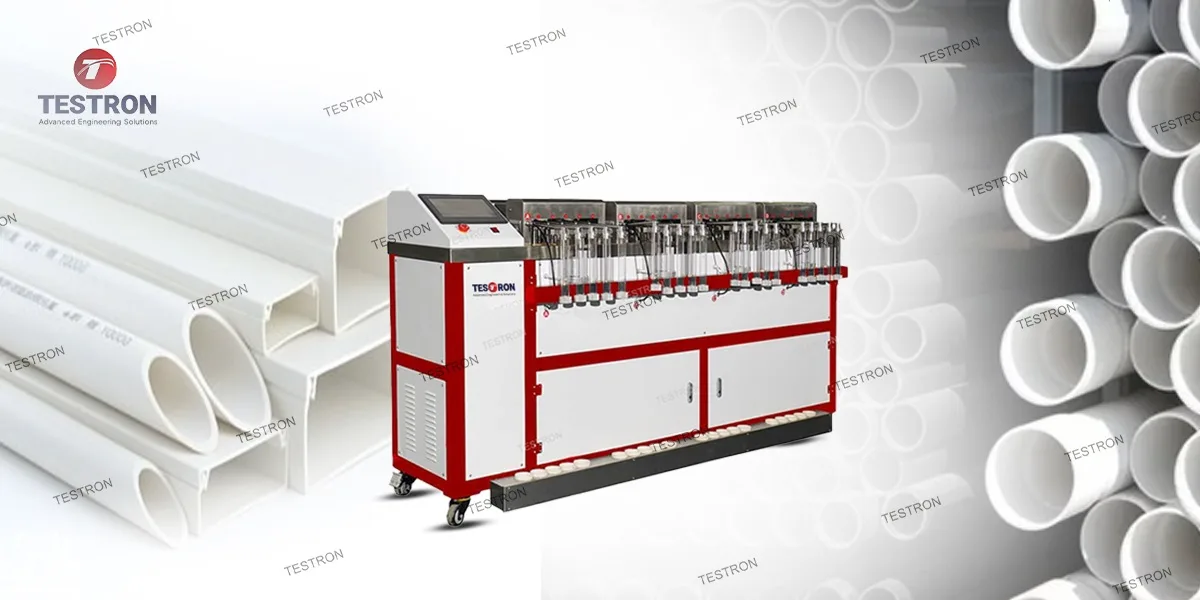

It is mainly applicable to materials involving HDPE in the plastic pipe manufacturing industry, such as plastics, packaging, and pipeline materials. And therefore, manufacturers demand reliability in the case of such a tester. The TT-UCLS Notched Constant Ligament Stress Tester by Testron is an example of a notable UCLS tester that is considered reliable across several manufacturing industries.

What Makes Stress-Cracking Resistance Testing Important

Stress cracking is a failure situation that is common in polymers and can reduce their lifespan. It can be called a silent failure as it is often difficult to detect, while also being harmful to the polymers themselves.

In the case of industrial applications, this failure can lead to packaging leakages, pipeline bursts, or even safety hazards. Furthermore, the tester follows the compliance standards, such as:

| Standard | What is it relevant for |

| ISO-16770 | This puts forward an isolated system to measure the resistance of stress cracking of polyethylene materials, such as HDPE. |

| ASTM 5397-99 | Evaluation of stress crack resistance of polyolefin geomembranes using a notched constant tensile load test. |

| ASTM F2136-18 | Notched, constant ligament-stress test to determine the stress-cracking resistance of HDPE resins. |

Table 1: The compliance standards important for stress-cracking resistance

Key Importance: The Cost of Failures

The most relevant aspect related to why stress-cracking resistance is important is the cost of the failure of the HDPE materials. To better explain this, let’s look into how cost of failures can be different from the preventive testing:

| Factors | Cost of failures | Preventive testing |

| Repair and Replacement | Replacement of failed equipment can be expensive. | Specialized testing measures can assess material property to ensure long-term performance (Example: UCLS). |

| Environmental Impact | Failures leading to environmental damage. | Environmental factor tracking can prevent overall degradation. |

| Material Loss | Failure can lead to loss of valuable material. | Pressure testing to confirm the overall reliability. |

| Labor Costs | Diagnosis, repair and clean-up costs after failure can be major. | Routine inspections and visual checks. |

Table 2: Cost of failures vs. preventive measurement chart

This chart has mentioned both routine testing and specialized testing measures. The notched constant ligament stress equipment, especially in the plastic pipe manufacturing industry, can be an essential preventive testing measure that can be a positive defensive strategy against the failure costs of plastic pipes.

How Top Manufacturers Use Notched Constant Ligament Stress Testers to Stay Ahead

The pipe manufacturing industry has been considered as an example in the previous section to discuss the relevance of UCLS testers. This is because this tester is the most useful in that industry that is the primary industry that deals with HDPE.

And here are the ways that the top manufacturers in the stated industry uses these testers to stay ahead:

- Quality Control: This helps detect the material weaknesses in the manufactured pipes before the product release.

- R&D Benefits: It helps manufacture more durable plastic pipes.

- Customer Trust: The delivery of reliable products which meet the international plastic pipe manufacturing industry standards.

- Competitive Edge: A product with a well-tested quality assurance leads to assured product consistency, making it easier to market.

It is these benefits that reliable UCLS testers, such as Testron’s TT-UCLS Notched Constant Ligament Stress Tester, provide to notable plastic pipe manufacturers across the globe.

Features of a High-Quality UCLS Tester

So, how can one identify a high-quality Notched Constant Ligament Stress Instrument? That will be perfectly identified by the features it will offer. Some of these features can be written as:

- A reliable UCLS tester has an accurate level control function. The accuracy of this level control can often be up to the smallest fragments of 2 mm, accurately controlling the concentration of the solution for the immersion of the test specimen.

- Some of the most well-known testers are automated, with a premium example in this context being Testron’s TT-UCLS. This automatically maintains the power loss, saving the test time and parameters in the case of unexpected power failures, along with automated loading and time calculations.

- These testers are also equipped with a good anti-corrosion function, protecting the tester from being corroded by the test liquid of tetrafluoroethylene.

- The Notched Constant Ligament Stress Equipment Price is also lower than the industry standards.

And more importantly, these features lead to declaring positive practices such as:

- Precise measurement and repeatability

- Automation features

- User-friendly design and interface systems

And with these comprehensive features in place, any plastic pipe manufacturing company can depend on the High-Quality UCLS Tester for the ideal desired results. And that is exactly what Notched Constant Ligament Stress Tester Manufacturers, such as Testron, focus on.

Summing Up

The notched constant ligament stress tester is an essential tool for manufacturing industries, especially in the pipe manufacturing industry that is notably dealing with HDPE. A reliable UCLS, such as Testron’s TT-class equipment, can apply its features to help pipe manufacturing companies stay ahead of the competition.

Considering a UCLS Tester? Learn More!

Want to consider an UCLS Tester for your pipe manufacturing plant? Why not learn more from some of the industry giants, such as Testron, to ensure that you completely understand how it works. And ensure that the HDPE pipes you manufacture are top class.