In-Depth Analysis: 4 Core Components Of Lithium Batteries And Their Manufacturing Processes

Lithium battery cathode and anode materials

The smartphone in your hand processes billions of operations every day, the screen emits millions of pixels of light, connects to 5G networks, plays videos, runs various apps… All of this is supported by a battery that is only a few millimeters thick. How does it do this? Let’s explore the technical core of lithium-ion batteries in depth, just like disassembling a precision instrument.

The cathode material is the most expensive, most critical, and most competitive. It accounts for 30%-40% of the total cost of the battery and determines how much energy the battery can store.

Now imagine that you want to build a building that can accommodate the most “lithium-ion residents”. Different cathode materials are different buildings.

Lithium cobalt oxide (LCO) is like a luxury apartment. Each unit is exquisitely designed and can accommodate many people (high energy density), but it is expensive and has average fire resistance (poor thermal stability). This is why early mobile phone batteries used lithium cobalt oxide – mobile phones need to be thin and light, and they are willing to pay a high price for it, and mobile phone batteries are small, so even if problems occur, they are relatively controllable.

Lithium iron phosphate (LFP) is like affordable housing. Although fewer people live in each unit (low energy density), it has a solid structure, is fireproof and shockproof (high safety), and is cheap and durable. BYD’s “blade battery” is a representative work of lithium iron phosphate. In 2020, BYD conducted an amazing experiment: piercing the battery with a steel needle, ordinary ternary lithium batteries instantly caught fire and exploded, while blade batteries only heated up slightly, with a surface temperature of only 60°C, and the eggs fried on it were not cooked.

Ternary materials (NCM/NCA) are a smart compromise, like a comprehensive community, finding a balance between capacity, cost and safety through a clever combination of three elements: nickel, cobalt and manganese. Tesla uses high-nickel ternary batteries, and the nickel content has increased from the initial 33% to more than 90% now. Why increase the nickel content? Because nickel is cheap and can provide high capacity, while cobalt is too expensive – taking the price of cobalt in 2022 as an example, it once soared to US$80,000 per ton that year.

Manufacturing these lithium battery materials is not simple.

Take NCM811 (nickel-cobalt-manganese ratio 8:1:1) as an example. First, in a huge reactor, nickel, cobalt, and manganese compounds must be “co-precipitated” at strictly controlled temperature and pH. This process lasts for 20-40 hours, during which the temperature error cannot exceed 1°C, the pH value must be accurate to 0.01, and the stirring speed must be just right – too fast will destroy the crystal structure, too slow will cause uneven mixing.

Next is high-temperature sintering. At a high temperature of 800-900°C, the precursor reacts with the lithium source to produce the final product. This temperature is very particular: too low will not react completely, and too high will destroy the structure. More importantly, the heating and cooling speeds are usually 10-20 hours to complete the entire heat treatment process.

The latest technology is “single crystalization” and “concentration gradient design”. Traditional cathode electrode materials are polycrystalline, like a pile of pebbles piled together, with many gaps and unstable structure. Single crystal materials are like a whole piece of gemstone, with a dense structure and good stability. The concentration gradient design is more ingenious: the high nickel content in the core provides high capacity, and the high manganese content in the outer layer ensures stability, just like putting on a protective suit for the high-energy core.

If the cathode electrode is the “home” of lithium ions, then the anode electrode is the “parking lot” where they work. The design of this parking lot directly determines how fast the battery can be charged and how long it can be used.

Graphite is currently the most successful anode material. Its structure is like a stack of books, and lithium ions can be inserted between the pages. Every 6 carbon atoms can accept 1 lithium ion to form a LiC₆ compound with a theoretical capacity of 372mAh/g. This number may not seem large, but it is stable – after tens of thousands of charge and discharge cycles, the structure is still intact.

But graphite has a fatal weakness: charging too fast will cause problems. For example, if the entrance of a parking lot is too narrow, there will be a traffic jam when the traffic is heavy. The “congested” lithium ions will not have time to “park” in an orderly manner, and will accumulate on the surface of graphite to form metallic lithium, which is “lithium dendrites”. The explosion of Samsung Note 7 in 2016 was partly caused by the growth of lithium dendrites.

In addition to graphite, silicon materials are the “rising star” in the anode electrode industry. The theoretical capacity is as high as 4200mAh/g, which is 11 times that of graphite! But silicon has a big problem: the volume expands by 300% when charging and shrinks back when discharging. Imagine if your mobile phone battery becomes 3 times thicker when charging and becomes thinner when running out of power. After a few times, the shell of the phone will crack.

Scientists have come up with various ways to deal with silicon materials. Tesla mixed 5-10% silicon into the Model 3 battery, using carbon materials to put a “tights” on silicon to limit its expansion. Professor Cui Yi’s team at Stanford University went a step further and designed a “yolk-eggshell” structure: silicon nanoparticles are egg yolks, wrapped in a layer of hollow carbon shell to leave space for silicon to expand. Amprius used this technology to make a 450Wh/kg battery, almost twice that of ordinary batteries.

Lithium battery electrolyte and separator

The electrolyte and the separator are equivalent to the “blood” and “blood vessels” of the battery. The combination of the two allows lithium ions to travel safely and quickly between the cathode and anode electrodes.

The typical electrolyte formula is like mixing a cocktail, which requires precise proportions and sequences. The “base wine” of the electrolyte is an organic solvent, usually cyclic carbonate (EC) to provide a high dielectric constant, and linear carbonate (DMC, EMC) to reduce viscosity. The “main ingredient” of the electrolyte is lithium salt, lithium hexafluorophosphate (LiPF₆) is the most commonly used, and the concentration is usually 1mol/L.

However, in the electrolyte, the most critical thing is various additives. Although the content is less than 5%, the effect is very large. For example, vinylene carbonate (VC), only 1-2% is added to form a dense protective film on the surface of the anode electrode to prevent the electrolyte from further decomposing. This is like applying a layer of varnish to the metal surface to prevent rust. Another example is fluoroethylene carbonate (FEC), which is a “good friend” of silicon anode electrodes and can adapt to the volume changes of silicon. Film-forming additives, flame-retardant additives, high and low temperature additives… Every battery factory has its own “secret recipe”.

Compared with cathode and anode electrode materials and electrolytes, the separator seems simple, but in fact it has a very high technological content. The mainstream polyethylene (PE) separator is only 10-20 microns thick, thinner than a hair, but it is covered with nano-scale micropores. These pores must just allow lithium ions to pass through and block electrons. Even better, the PE separator will melt at 135°C, automatically close the pores, cut off the ion channel, and prevent thermal runaway – this is called the “thermal shutdown” function.

High-end batteries use composite separators, such as SK’s ceramic coated separator, which is coated with a layer of nano-alumina on the PE base film. This layer of ceramic can both improve heat resistance (ceramics are not afraid of high temperatures) and improve wettability (electrolyte is easier to penetrate).

The “wet” process for making separators can be called industrial art. First, PE is mixed with paraffin oil, extruded into a film, and then the paraffin oil is extracted with a special solvent, leaving micropores. Finally, biaxial stretching is performed to adjust the pore size and distribution. The entire process requires extremely high cleanliness, as a speck of dust may cause a separator to perforate.

Lithium battery production and safety protection

If materials are the “hardware” of lithium batteries, then the manufacturing process is the “software”. The same material, different processes, may have performance differences of more than 30%. From mixing to finished products, every process contains the ultimate engineering wisdom.

Making battery slurry;

High-precision coating process;

Rolling process, pressure control;

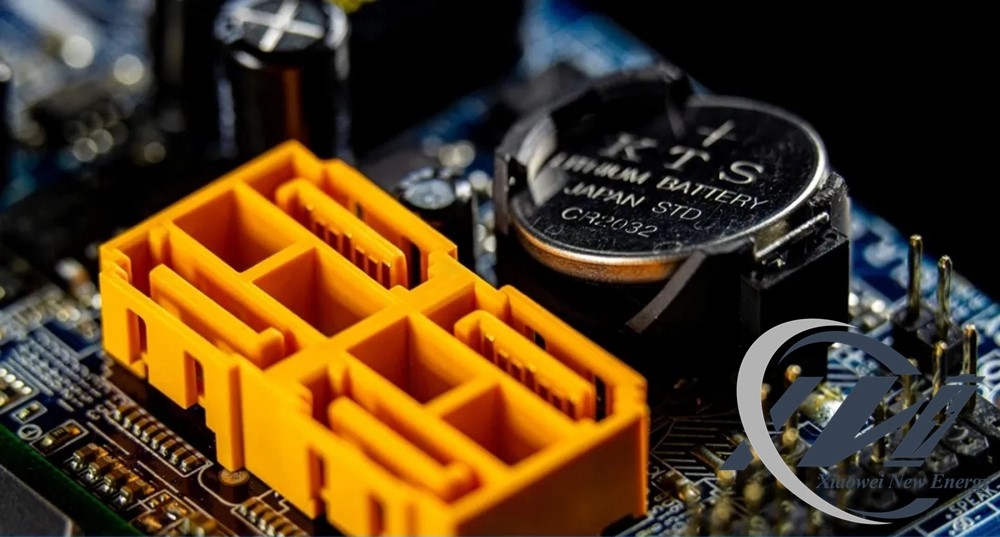

Battery cell assembly: In the “drying room” with a humidity of less than 1%, workers wear special anti-static clothing and work carefully. In such an environment, the injection process is even more precise: the electrolyte is injected under a vacuum environment, and the amount is accurate to 0.01 grams to ensure that every corner of the electrode is completely soaked.

During the battery formation process, when charging for the first time, it should be carried out slowly with a very small current to allow the SEI film to form evenly. This layer of film, which is only a few nanometers thick, determines the life of the battery. It is said that Tesla’s formation process has as many as a dozen steps, including a subtle combination of different temperatures and different currents, and the whole process takes 3-7 days.

Security issues

Thermal runaway is the most common chain reaction of lithium batteries. It unfolds like a domino: SEI membrane begins to decompose at 90℃, the anode electrode reacts with the electrolyte at 120℃, the diaphragm shrinks at 150℃ causing an internal short circuit, the cathode electrode decomposes and releases oxygen at 180℃, and the electrolyte decomposes on a large scale at 200℃. The heat released during the whole process causes the temperature to rise sharply to 800℃, which is enough to ignite everything around.

The fire accident of Tesla Model S in 2013 became a turning point for the industry. The accident caused by metal fragments on the road piercing the battery pack prompted the entire industry to re-examine safety design. Tesla’s response is textbook-level: adding titanium alloy guards, improving the cooling system, and optimizing the battery management algorithm. Today’s Tesla battery pack can control the fire within a single module even if it is pierced by a steel nail.

The most cutting-edge research is giving batteries “intelligence”. The smart diaphragm developed by Stanford University automatically increases resistance to limit current when the temperature exceeds the threshold. Micro sensors are implanted inside the battery cell to monitor various parameters in real time. These innovations give the battery a “nervous system” that can sense and actively respond to danger.

As the wave of electrification advances, battery recycling is forming a complete industrial chain. By 2030, there will be 11 million tons of waste batteries to be processed worldwide.

The next time you charge your phone, think about the grand world behind this small battery – there are countless scientific researchers’ hard work, the courage and wisdom of human beings to challenge the limits of nature, and our beautiful expectations for a sustainable future. The legend of lithium-ion batteries continues, with new breakthroughs happening every day.