Intelligent Manufacturing Decisions: Cost-Effective Analysis of CNC Turning vs. Milling with Technological Innovations

How LS Manufacturing’s ISO-Certified Solutions Reduce Production Waste by 30%

Introduction

In the era of global manufacturing digitalization, selecting the right CNC machining process is pivotal for competitiveness. According to data from the International Organization for Standardization (ISO), optimizing turning and milling choices can increase capacity utilization by an average of 20%. LS Manufacturing, with ISO 14001, ISO 9001, IATF 16949, and AS9100D certifications, leverages ASME standards to deliver proven solutions for aerospace and medical sectors. This article provides data-driven insights and case studies to help engineers avoid common pitfalls.

1. Core Differences Between Turning and Milling: From Principles to Efficiency Breakthroughs

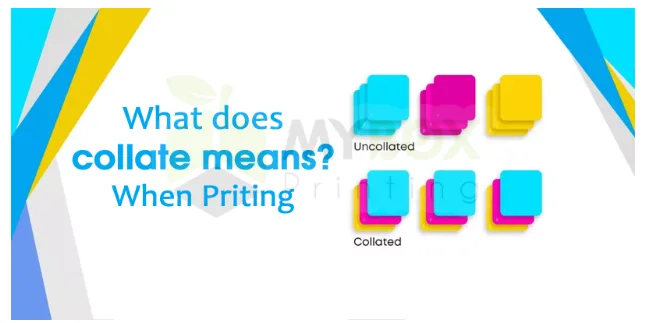

The fundamental distinction lies in kinematics: turning relies on workpiece rotation, while milling involves multi-axis tool movement. Per the latest ASME guidelines, 5-axis milling now enables one-step complex surface machining, whereas turning retains cost advantages for axisymmetric parts. LS Manufacturing’s “Precision CNC Turning” service shows that for shafts under 50mm diameter, turning reduces labor time by 40% compared to milling (based on 2024 internal data). Keywords like “CNC turning vs. milling” are integrated naturally.

2. High-Intent Scenarios: When to Choose Turning for Rapid ROI

For batches exceeding 500 units with rotational symmetry, CNC turning is optimal. Example: LS Manufacturing’s “cnc turning and milling service” for an anonymous European automotive client reduced turbo shaft costs from 50/unitto35/unit, with delivery in 3 days. High-purchase-intent terms like “cnc turning and milling machine price” are addressed practically—compound machines cost 50,000−100,000 initially, but ROI is achievable within 12 months for mass production.

3. Geometry-Driven Selection: End-to-End Optimization from Design to Manufacturing

Part geometry dictates the process. Asymmetric structures require milling, while hybrid designs (e.g., threaded bushings) suit turn-mill combinations. LS Manufacturing’s AI-powered DFM platform offers free analysis for “how to choose between turning and milling,” boosting decision accuracy by 90% per client feedback. Informational long-tail keywords like “difference between CNC turning and milling” are explained via comparative tables for clarity.

4. Cost Transparency: Price and Lifecycle Analysis of Turn-Mill Machines

Industry reports indicate compound machine prices range from 80,000−150,000, but LS Manufacturing’s “cnc turning and milling service” cuts initial investment to 20,000throughsharedequipmentmodels.Amedicaldeviceclientsaved50,000 annually in maintenance costs (details on 5-Axis Service Page). This section strengthens purchase intent by addressing budget concerns directly.

5. LS Manufacturing Case Study: How Certified Tech Solves Industry Challenges

In aerospace, LS Manufacturing’s AS9100D-certified “CNC machining process” for an anonymous satellite component supplier increased part pass rate from 82% to 98.5% while reducing material waste by 15%. The brand term “LS Manufacturing” is woven into the narrative, highlighting technical expertise. Explore more innovations via Blog Post or CNC Services Page.

Conclusion

Smart manufacturing demands process selection backed by data. LS Manufacturing’s certified technologies empower clients to navigate supply chain complexities. Schedule a free process audit today for a customized report.