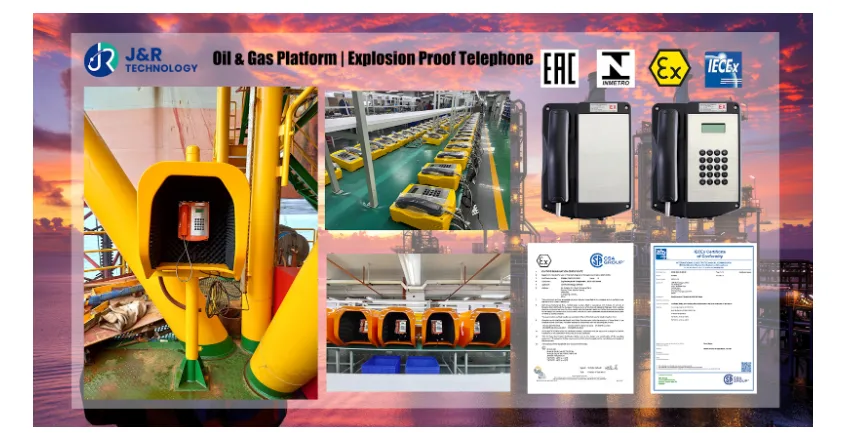

J&R’s ATEX/IECEx-Certified Explosion-Proof Equipments Ensure Maximum Safety And Help Clients Meet Regulatory Requirements Effortlessly

Safety is the first thing companies think about when they work in places where fire, gas or dust explosions can happen. Any small spark can lead to a big accident. That is why many industries depend on J&R’s ATEX/IECEx-Certified Explosion-Proof Equipments. These products are designed to work safely in harsh areas without causing danger. They also help companies follow important safety rules without stress. We will look at how these certified products work and why the certifications matter. This article will help you understand how different industries use the equipments every day.

Understanding the Role of Explosion-Proof Equipment in High-Risk Industries

Explosion proof devices are suitable for locations where flammable gas, dust, vapors or chemicals are present. Oil fields, offshore platforms, chemical plants and mines are mostly such fields. A small electrical spark is enough to start an explosion in these areas. Unprotected equipment can fail and put workers at risk.

Explosion-proof devices reduce this danger because:

- They keep internal sparks or heat from escaping.

- They stop external flammable materials from entering the device.

- They work reliably even in rough weather and heavy dust.

Many companies use J&R’s ATEX/IECEx-Certified Explosion-Proof Equipments because the products go through strict testing before being approved for such dangerous areas.

Another important part of safety is communication. Here, the explosion-proof telephone product plays a big role. Teams working in remote or risky zones use these phones to stay connected during daily operations or emergencies. These phones are built to survive fire, dust and water so workers can call instantly when something goes wrong.

The Meaning and Importance of ATEX and IECEx Certifications

ATEX and IECEx are two international systems that test and approve equipment used in explosive environments. They make sure the device is safe and will not trigger an explosion.

What ATEX Means

ATEX is the European standard for equipment that makes the device safely workable in explosive atmospheres. The product with ATEX certification means it has passed strict checks related to construction, materials and safety performance.

What IECEx Means

IECEx is a global certification system. Many countries use it to approve safe equipment for dangerous locations. The certification shows that the product meets international safety levels and is trustworthy in different regions.

These pairs of certifications are important because companies do not want to risk accidents or legal problems. By choosing J&R’s ATEX/IECEx-Certified Explosion-Proof Equipments, clients can show inspectors and authorities that they follow global safety rules.

These certifications also include explosion proof telephone certificates, which prove that the communication devices used in risky environments meet all required standards.

How J&R Products Help Clients Achieve Compliance with Ease

Many companies find certification requirements confusing. They must choose equipment that fits their region, environment and legal safety rules. J&R makes this process simple.

Complete Certification Support

J&R supports clients with full certification guidance, including ATEX, IECEx, EAC and INMETRO. Their documents help companies during audits and inspections of the products. They help by easing the project approval stages. Clients do not have to search for details because the information is clear and easily understandable.

Available Safety

Most J&R’s ATEX/IECEx-Certified Explosion-Proof Equipments comes with compliance support already included. The company provides:

- Technical manuals

- Safety test reports

- Explosion-proof telephone certificates

- Installation guides

- Long-term field support

Companies working in chemical zones, oil rigs or mining sites often choose J&R because the products match local and international rules without extra work.

Is It Really Possible

A mining company in Colombia installed J&R’s ATEX-certified explosion-proof telephone in an underground coal mine. The phone’s rugged aluminum-alloy body, armored handset cord, and full keypad worked reliably under dust, humidity, and potentially explosive gases — and the customer reported very good performance.

Another instance is installing J&R’s JREX106 series telephones across offshore oil and gas drilling platforms (onshore and offshore) around the world. These certified phones are able to work with safety in Zones 1, 2, and 22, resisting salt spray, vibration, moisture, and dust. Additional accessories, like explosion-proof alarms and noise-proof hoods, helped maintain reliable communication even under harsh environmental conditions.

Built for Safety: Key Features of J&R’s Certified Equipment

Strong Construction

All J&R’s ATEX/IECEx-Certified Explosion-Proof Equipments is made with heavy-duty materials. The housings resist fire, chemicals, saltwater and dust. This keeps the internal parts safe even in long-term use.

Safe Electrical Design

The wiring and circuits are built to avoid sparks. Even if the equipment gets hit, dropped or exposed to harsh weather, it does not release heat that can start a fire.

User-Friendly Operation

The buttons, screens and audio parts are easy to use even when workers wear gloves. This is important for quick communication in emergencies.

Waterproof and Weatherproof

Many of J&R’s devices have high IP protection levels. They can resist rain, storms, humidity and extreme temperatures.

Long-Lasting Parts

The mechanical parts are built for long use with very little maintenance. This helps reduce downtime and saves money for clients.

Application Scenarios: From Chemical Plants to Offshore Platforms

Different industries trust J&R’s ATEX/IECEx-Certified Explosion-Proof Equipments in places where danger is always present.

Chemical Plants

Chemical production includes flammable liquids and gases. J&R phones and devices allow workers to call instantly if something spills or leaks. Their equipment stands strong against corrosive materials.

Oil and Gas Fields

Both onshore and offshore rigs use J&R products because they can survive salty air, heavy winds and tough working conditions. Workers can depend on their communication tools even during storms.

Mining Sites

Dust explosions are common in mines. J&R equipment prevents sparks and supports clear communication deep underground.

Factories and Storage Warehouses

Industries that store paint, fuel, food grains or chemicals use J&R products to reduce fire risks and follow safety rules.

In all these places, the explosion-proof telephone product is one of the most needed tools. Workers rely on it for daily tasks and safety checks with immediate contact in emergencies.

Conclusion

J&R’s ATEX/IECEx-Certified Explosion-Proof Equipment gives companies strong safety and reliable performance with stress free compliance. They offer tested, certified and trusted products in some of the most dangerous locations. With support for global certificates and equipment made for tough conditions, clients can meet safety rules without trouble. These solutions help reduce risks and keep workers safe in every environment where danger is possible.