Key Industrial Applications of Overhead Crane Malaysia

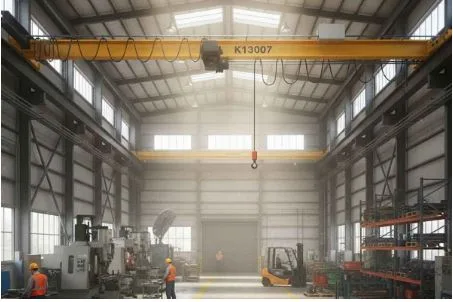

Overhead Crane Malaysia plays a vital role in Malaysia’s industrial sector, enabling the efficient handling of heavy materials, enhancing workplace safety, and improving overall productivity. These cranes are widely used in industries ranging from manufacturing to energy production, where precision, strength, and reliability are critical. Malaysia, with its growing industrial sector, has seen an increasing reliance on overhead cranes for tasks that require moving massive loads safely and efficiently.

The versatility of overhead cranes makes them indispensable in environments where lifting heavy or bulky materials manually would be impossible or highly inefficient. By integrating advanced control systems, load monitoring, and safety mechanisms, these cranes have become key assets in boosting operational efficiency. Their applications span multiple sectors, ensuring streamlined workflows and cost-effective operations.

Heavy Manufacturing & Steel Production

Steel Mills

Steel mills in Malaysia rely heavily on overhead cranes to transport raw materials, molten steel, and finished products within production areas. These cranes handle extremely heavy loads, such as steel coils and slabs, with precision, reducing the risk of accidents and damage. Overhead cranes are often equipped with high-capacity hoists and robust structural designs, enabling safe handling in high-temperature and demanding environments.

Efficient material flow in steel mills is essential for maintaining productivity. Overhead cranes help streamline processes by minimizing manual handling and improving the speed of transporting materials between furnaces, rolling mills, and storage areas. Their integration allows steel mills to operate at higher capacities while maintaining strict safety standards.

Metal Fabrication

Metal fabrication plants also benefit from Overhead Crane Malaysia, which move large sheets, structural beams, and fabricated components throughout workshops. These cranes ensure precise placement of heavy parts during cutting, welding, and assembly processes. By automating heavy lifting tasks, fabricators reduce labor strain and improve operational efficiency.

In addition, overhead cranes in metal fabrication support modular and repetitive production lines. They allow operators to handle large-scale components without compromising safety, while also optimizing floor space. This capability is critical in modern Malaysian factories that aim to maintain competitiveness in both domestic and international markets.

Automotive & Transportation

Assembly Lines

In the automotive sector, overhead cranes play a pivotal role in assembly lines. They lift and position heavy vehicle components, including engines, chassis, and transmission systems, ensuring precise alignment during assembly. This reduces production bottlenecks and enhances the speed of vehicle manufacturing.

The use of overhead cranes in automotive assembly lines also improves workplace safety. Manual handling of heavy components is minimized, which reduces the risk of worker injuries. Moreover, cranes equipped with automated controls can maintain consistent quality standards and repeatability in production, which is crucial for high-volume automotive manufacturing.

Workstation Precision

Overhead cranes provide high-precision lifting for workstation operations in transportation equipment manufacturing. Components such as axles, suspension systems, and gear assemblies require careful handling to maintain alignment and structural integrity. Cranes with fine movement control allow operators to position these components accurately without excessive manual intervention.

In addition, workstation cranes facilitate flexible layouts. Malaysian automotive and transportation factories can adapt quickly to changes in production requirements, switching between vehicle models or manufacturing processes with minimal downtime. This flexibility is an important factor in maintaining competitiveness in the region.

Oil & Gas and Petrochemicals

Equipment Maintenance

Overhead cranes are crucial in oil, gas, and petrochemical facilities for the maintenance of heavy equipment. Pumps, turbines, and industrial compressors are frequently lifted for servicing or replacement. Cranes allow these operations to be performed safely, reducing downtime and ensuring operational continuity in high-stakes environments.

These cranes also aid in transporting raw materials and chemicals safely within plant premises. With controlled lifting and precise positioning, overhead cranes minimize the risk of spills, damage, or accidents, which are critical concerns in hazardous environments such as chemical processing units.

Explosion-Proof Systems

In certain petrochemical applications, overhead cranes are designed with explosion-proof systems to operate safely in flammable or volatile atmospheres. These cranes are engineered to prevent sparks and static discharge, ensuring compliance with stringent safety regulations.

Malaysia’s oil and gas facilities leverage these specialized cranes to transport sensitive equipment and materials safely. Explosion-proof cranes enable the industry to maintain rigorous safety standards while handling heavy machinery, reducing the risk of industrial accidents in environments prone to fire or chemical hazards.

Warehousing & Logistics

Cargo Handling

Overhead Crane Malaysia is extensively used in warehousing operations for lifting and moving heavy cargo. They enhance efficiency in loading, unloading, and storing goods, particularly in bulk storage or high-volume warehouses. By reducing reliance on forklifts for extremely heavy items, cranes improve safety and speed up material handling processes.

These cranes also support operations in specialized storage facilities, such as cold storage warehouses or high-density racks. For outdoor container handling, facilities often rely on Gantry Cranes Malaysia, which are specifically designed for lifting and moving extremely heavy loads across ports and open storage areas. This enables operators to maximize storage space and efficiency in Malaysia’s competitive logistics sector.

Port & Dockside Support

Ports and dockside facilities in Malaysia rely on overhead cranes for container handling and ship loading/unloading operations. These cranes move heavy cargo between vessels and storage areas efficiently, ensuring smooth logistical flows and reducing turnaround times for ships.

The cranes used in port operations are often designed for durability and high-capacity lifting. They operate in harsh environments, resisting corrosion from saltwater exposure while maintaining operational precision. This ensures that Malaysia’s maritime logistics infrastructure can handle global shipping demands effectively.

Shipbuilding and Marine Engineering

Hull Assembly

Shipbuilding operations involve the assembly of massive hull sections, which cannot be managed manually. Overhead cranes lift and position these sections accurately, enabling workers to weld, fasten, and align components safely. This reduces construction time while maintaining structural integrity.

The precision provided by overhead cranes is crucial in maintaining dimensional accuracy. In Malaysia, shipyards rely on cranes to handle hull plates, prefabricated modules, and bulkheads, ensuring that each vessel meets international safety and performance standards.

Engine Installation

Overhead Crane Malaysia also facilitates the installation of heavy marine engines and propulsion systems. These engines can weigh several tons, and precise placement is essential for optimal alignment and operational efficiency.

Cranes with fine control and high lifting capacity are indispensable for this task. By enabling careful positioning, overhead cranes prevent damage to costly machinery, minimize installation errors, and reduce downtime during vessel construction.

Power Plants & Infrastructure

Turbine Halls

Overhead cranes are vital in power plants for lifting and installing turbines, generators, and transformers. These components are extremely heavy and must be handled with extreme care to avoid operational issues. Cranes ensure safe and precise positioning in turbine halls, where space is often limited.

Maintenance operations also benefit from overhead cranes. Replacing or servicing large components in power plants requires precise lifting capabilities to prevent structural damage. In Malaysia, these cranes contribute to efficient plant operations and reliable energy production.

Precast Concrete

Infrastructure projects often rely on precast concrete components such as beams, columns, and slabs. Overhead cranes lift and transport these heavy elements within construction sites, reducing manual labor and improving construction speed.

Cranes enable accurate placement of precast components, ensuring structural integrity and adherence to design specifications. Malaysian construction projects benefit from overhead cranes’ ability to handle large-scale infrastructure efficiently, supporting rapid urban development and industrial expansion.

Why Power Tiek Stands Out?

Power Tiek Sdn. Bhd. is a leading provider of overhead and gantry cranes in Malaysia, known for quality, innovation, and reliability. They design and supply cranes for various industrial applications, ensuring safe and efficient operations. Their solutions are tailored for sectors like manufacturing, logistics, shipbuilding, and power infrastructure.

The company emphasizes advanced technology, precision lifting, and compliance with international safety standards. Power Tiek also provides excellent after-sales support and maintenance, making them a trusted partner. Their focus on quality and service ensures long-term value for industrial clients across Malaysia.

Conclusion

Overhead Crane Malaysia is indispensable across Malaysia’s industrial sectors, from manufacturing and automotive production to oil and gas, logistics, shipbuilding, and power infrastructure. Their ability to lift heavy loads with precision enhances safety, efficiency, and productivity, making them essential tools in modern industrial operations.

The widespread use of overhead cranes underscores their versatility and importance. As Malaysia continues to expand its industrial and infrastructure capabilities, the integration of advanced overhead crane systems will remain a key factor in supporting sustainable growth and maintaining competitiveness in the global market.