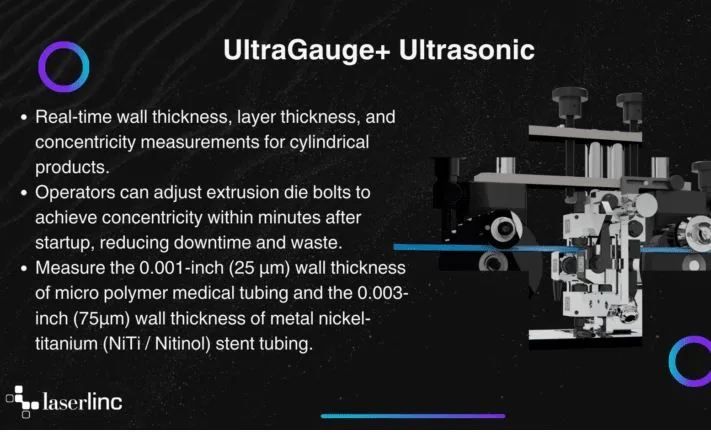

LaserLinc Makes Headlines with UltraGauge+: Setting a New Standard in Ultrasonic Measurement for Precision Manufacturing

As industries around the world continue to demand higher quality standards and tighter tolerances, manufacturers are increasingly turning to advanced technologies to maintain their competitive edge. At the forefront of this evolution is LaserLinc, whose UltraGauge+ series of ultrasonic systems is reshaping how companies think about in-line measurement and quality control.

A recent press release highlights how UltraGauge+ is revolutionizing the way manufacturers approach complex wall thickness and concentricity checks — all without slowing production lines.

Why Manufacturers are Investing in Real-Time Ultrasonic Measurement

From plastic and rubber extrusion to multi-layer medical tubing and high-spec automotive hoses, today’s products often require exacting wall thickness and structural integrity. Traditional sample-based inspection simply can’t keep up.

UltraGauge+ changes the game by bringing in-process, non-contact measurement right to the production floor. This means:

- Operators receive immediate feedback on every inch of product — not just random samples.

- Deviations are flagged the instant they occur, allowing for quick corrections.

- Scrap rates plummet, and process yield increases, directly impacting the bottom line.

It’s no wonder more manufacturers see real-time ultrasonic measurement as not just an option, but a necessity for staying competitive.

Multi-Layer, Multi-Channel: Built for Today’s Most Demanding Applications

LaserLinc engineered UltraGauge+ to be remarkably flexible. Unlike older systems that might only measure a single layer or simple tube geometry, UltraGauge+ can simultaneously track multiple layers, inside diameters (ID), outside diameters (OD), total wall thickness, and concentricity.

This makes it ideal for advanced applications like multi-layer fuel lines, catheter tubing, or even thick industrial hoses where internal layer integrity is critical. It ensures nothing gets missed — no matter how complex the product profile.

http://drive.google.com/file/d/1mYRZR8B9dkmDQ6CP2vuUe8dehR_S-5oU/view?usp=drive_link

Easy Integration for Maximum Uptime

One of the reasons UltraGauge+ is gaining so much industry traction is its ease of integration. The systems mount seamlessly into existing production lines and are designed to work across a wide range of cooling environments and material types.

Plus, with LaserLinc’s modular approach and intuitive software tools, calibration is straightforward, and ongoing operation becomes second nature for teams. Less downtime and simpler training mean faster ROI and more consistent product quality.

Explore how an ultrasonic wall thickness gauge like UltraGauge+ can be tailored to your unique process. The system’s adaptability is one of the reasons manufacturers in medical, automotive, aerospace, and energy markets are moving quickly to adopt this technology.

Reducing Scrap and Strengthening Compliance

Every manufacturer knows the cost of scrap isn’t limited to raw material — it’s also lost production time, energy, and sometimes entire orders. UltraGauge+ dramatically cuts this risk by catching problems the moment they start, instead of after an entire spool or lot is produced.

This also supports rigorous compliance needs. Automated data logging and advanced reporting capabilities give quality teams the documentation they need for customer audits and regulatory bodies.

Discover more on how ultrasonic measurement like UltraGauge+ ensures processes stay within spec and that you can prove it with data-backed confidence.

A Partner That Goes Beyond the Hardware

Of course, none of this would matter without the strong application knowledge that backs it up. LaserLinc isn’t just delivering world-class measurement devices; they’re providing a partnership. Their engineers work hand-in-hand with manufacturers to configure systems for exact needs, whether retrofitting legacy lines or launching new high-spec production cells.

In today’s fast-paced manufacturing landscape, standing still simply isn’t an option. LaserLinc’s UltraGauge+ ultrasonic systems give companies a proven way to push their process capabilities further, reduce costly surprises, and meet the market’s ever-tightening demands with confidence.

For manufacturers looking to turn advanced measurement into a true production advantage, LaserLinc continues to prove why they’re an industry leader — one perfectly measured product at a time.