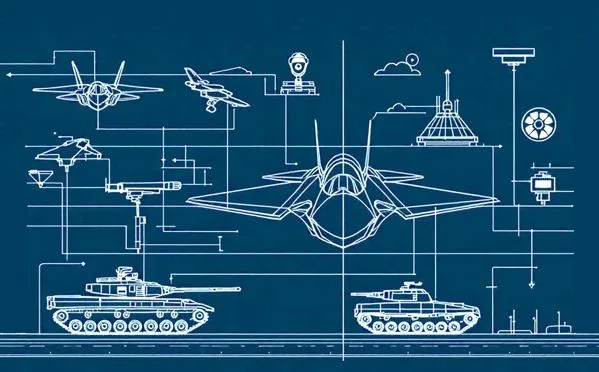

Leading Innovation in EO IR Systems: A High-Tech, High-Stakes World

How Angelique X. Irvin built a technology company that has achieved more than two decades of double-digit growth in one of the world’s most demanding industries—defense and aerospace—through superior hardware, private ownership, and a relentless team.

When global supply chains seized during the pandemic and geopolitical tensions rose, the defense industrial base relearned a hard lesson: technology only changes outcomes when paired with superior hardware designs and the will to keep improving it.

For Angelique X. Irvin, Founder and CEO of Clear Align, that conviction has powered over 22 years of consecutive growth above 35 percent, turning a bootstrapped optics shop into a trusted leader in EO/IR systems and C5ISR for national security. Clear Align leverages advanced sensor fusion to enhance the performance and situational awareness of its EO/IR systems.

From Bell Labs to Hardware-First Surveillance and Reconnaissance Platforms

Irvin began as a material scientist at AT&T Bell Laboratories, helping commercialize lithium-niobate optical modulators—precision devices that still drive high-speed networks. The takeaway was clear: winning in defense demands disciplined development, durable design, and execution under pressure.

Armed with a Ceramic Engineering degree from Alfred University and an MBA from Wharton, she founded Clear Align in 2003 to deliver surveillance solutions designed to protect lives. Two decades later, the company delivers advanced autonomous infrared systems and subsystems across land, sea, air, and space—supporting reconnaissance, border security, and complex surveillance operations where time, range, reliability, and enhanced situational awareness decide mission outcomes.

Why Superior Hardware Wins

Clear Align’s edge comes from fundamentals: glass quality, coatings, mechanics, optical design, and system-level integration. Software evolves quickly at the company, but photons and physics rule performance.

The firm’s vertically integrated chain—materials → optics → assemblies →software→ integration → AI-enabled processing —yields cleaner signals, better intelligence, and dependable range for identifying targets under stress.

Across 100,000+ square feet of production—35,000 square feet of it dedicated to optical fabrication—the team converts raw germanium into polished lenses and integrates them into complete EO/IR systems for fixed and mobile sites, where thermal imaging is a core capability. By owning the works, Clear Align manages risk, holds tolerances, and ensures lead times that match operational requirements.

“You can’t outsource ingenuity,” Irvin says. “When the mission is critical, you need mastery of your materials, your process, and your people. Superior hardware is what makes everything else possible.”

Private Ownership = The Long Game

Because Clear Align is privately owned, it can invest for the long game: product development done commercially using MOSA and SOSA architectures for modular systems that can e configured for many customers and applications, even new optical coating chemistries that are more rugged and have better transmission or better laser filter protection, manufacturing methods with tighter tolerancing, and next-generation integration and engineering that shrinks SWaP (size weight and power consumption) while improving performance.

It also resists the industry’s temptation to hollow out manufacturing. Instead, the company deepens capabilities in fabrication and precision assembly—the slow, capital-heavy work that becomes decisive in challenging supply chain environments that are politically controlled.

That patient posture—combined with gritty execution—has sustained Clear Align’s growth through downturns, pandemics, supply shocks, and policy changes. In 2025 alone, more than 966 small businesses across the defense sector shut down, victims of volatile supply chains and rising capital costs. Yet Clear Align grew bookings by over 120 percent, continuing its 22-year record of expansion. The company’s resilience has earned deep trust from the Department of War and the major defense contractors that support it—proof that persistence and performance still win in America’s most demanding industry.

A Technical and Leadership Bench Built for Hard Problems

Scaling that performance required a team that has led some of the industry’s biggest programs. The CTOs who joined from Fortune 500 defense contractors brought decades of experience in sensor physics, embedded processing, image processing, and platform integration—the kind of expertise that turns complex system requirements into mission-ready solutions. The CFO, who previously managed major divisions of public companies, introduced enterprise-grade program controls, disciplined forecasting, and capital stewardship while maintaining the agility that only a privately owned company can sustain.

Most importantly, Clear Align’s engineers understand innovation at the molecular level—from the physics of optical systems to the behavior of infrared detectors in dynamic thermal environments. They tackle problems others avoid and deliver designs that work in any environment when in the field. It’s a culture built on equal parts invention and execution—an obsession with getting every micron, photon, and parameter right.

Ensure Speed of a Private Company

This blend of public-company rigor and private-company speed keeps promises realistic and deliverables precise. Factory truth sets every baseline, and difficult performance requirements—thermal drift, image quality, infrared stability, and detection accuracy—are tracked with the same intensity as cost and schedule. The result is a company that doesn’t just innovate on paper—it delivers dependable hardware that performs under fire.

The Cadre: Credit Where It’s Due

Ask Irvin about Clear Align’s rise, and she credits a cadre of exceptional engineers and technicians who attack the toughest details every day: killing ghost images in complex optical systems, chasing nanometers on aspheres, squeezing SNR from low-contrast scenes with software advancements, all of which improves detecting faint signatures in complex scenes. They design for real-time exploitation, advanced night vision capabilities for EO/IR systems, fuse multispectral data into actionable intelligence, and keep operators safe with reliable hardware.

“I’m fortunate to work with people who love the hard stuff,” Irvin says. “Our growth belongs to them—and to the leaders and customers who believed in Clear Align.”

Hardware-Grounded AI for Decision Advantage

Clear Align merges machine learning with multispectral sensing—visible, SWIR, MWIR, LWIR, and radar—to deliver real time awareness for military operators. By combining these technologies, advanced threat detection becomes a critical outcome, enabling operators to identify and respond to dangers more effectively. Each IR spectrum has a different mission:

- SWIR (Short-Wave Infrared): Penetrates haze, smoke, and fog for clear imaging in degraded visibility.

- MWIR (Mid-Wave Infrared): Detects heat signatures from warm bodies, vehicles, and engines and provides scene awarness .

- LWIR (Long-Wave Infrared)): Measures subtle temperature differences for thermal contrast and scene awareness.

But algorithms are only as good as the photons they get; the decisive factor is still hardware. Superior optics, stable benches, and robust packaging feed clean data to AI for identifying threats, tracking targets, and accelerating outcomes in combat and crisis.

Deployed on unmanned aircraft, fixed towers, vehicles, and maritime masts, these platforms support reconnaissance and surveillance while integrating quickly with command networks for real time response.

Cybersecurity by Design

Security is built in, not bolted on. Clear Align designs trusted pathways from sensor to agencies, with secure communications that keep collected intelligence secure from digital intruders.

Grit, Not Hype

Sustained growth in defense hardware is rare. Procurement is slow, standards are unforgiving, and competitors are ruthless. Clear Align’s progress came from the use of disciplined methods, vertical integration, and hands-on expertise—not shortcuts. The company partners with frontline forces and program experts to translate field feedback into optical, mechanical, and firmware refinements that improve performance, raise yield, and boost reliability.

Rapid Response Beyond the Battlespace: Border Security Applications

Clear Align’s platforms also support emergency response at ports and critical infrastructure, augmenting traditional drones and mobile kits with multispectral surveillance for search-and-rescue and damage assessment. Rugged hardware and modular cameras let agencies adapt applications quickly as state and local needs evolve.

Restoring America’s Industrial Backbone

Irvin champions modernizing technology and materials processing at home—rare-earth refinement, optical manufacturing, and secure packaging—so the nation can protect supply chains and reduce strategic exposure. She argues that financing should reward new technologies, not only legacy tooling, and that resilient factories are as vital as code to future readiness.

See Clearly. Act Decisively.

Clear Align’s story is about grit—and the patience to invest in the fundamentals. With EO/IR systems tuned for range and clarity, vertically integrated capabilities, and leaders who’ve run billion-dollar programs, the company keeps delivering under pressure. For more than two decades, a mission-driven culture and hardware obsession have produced consistent success for operators on the battlefield and at the border—helping them detect and defeat threats in time.

Irvin puts it simply: the long game belongs to superior hardware—and to the teams determined to build it.