Material Handling Hose: A Complete Guide to Industrial Efficiency and Safety

In industrial environments where bulk materials are transferred daily, choosing the right material handling hose is critical. From powders and pellets to abrasive granules and liquids, these hoses play a vital role in maintaining productivity, safety, and system longevity. This guide explores what a material handling hose is, how it works, its applications, benefits, and key factors to consider when selecting the right hose for your operation.

What Is a Material Handling Hose?

A material handling hose is a specialized industrial hose designed to convey solid, semi-solid, or liquid materials efficiently and safely. These hoses are engineered to withstand abrasion, pressure, temperature variations, and chemical exposure commonly found in manufacturing, construction, agriculture, and processing industries.

Unlike standard hoses, a material handling hose is reinforced with durable layers that provide flexibility while resisting wear and tear caused by heavy or abrasive materials.

Common Applications of Material Handling Hose

Material handling hoses are used across a wide range of industries due to their versatility and durability.

Industrial Manufacturing

In factories, a material handling hose transports raw materials such as plastic pellets, metal shavings, and powdered chemicals between processing units.

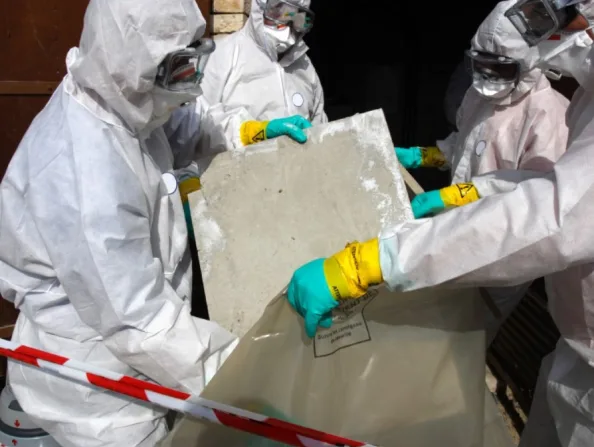

Construction and Mining

Construction and mining operations rely on material handling hose systems for transferring sand, cement, gravel, and slurry. These hoses are built to resist abrasion from coarse materials.

Agriculture and Grain Handling

In agricultural settings, material handling hoses are commonly used for moving grain, seeds, fertilizers, and animal feed efficiently without contamination.

Food and Pharmaceutical Processing

Specialized food-grade material handling hose options are designed to meet hygiene standards while transporting sugar, flour, powders, and other consumable materials.

Key Benefits of Using a Material Handling Hose

Choosing the right material handling hose offers several operational advantages.

Improved Efficiency

A properly selected material handling hose ensures smooth material flow, reducing blockages and downtime.

Enhanced Safety

These hoses are built to handle high pressure and abrasive materials, minimizing the risk of leaks, ruptures, or workplace accidents.

Long Service Life

High-quality material handling hose designs resist abrasion, chemicals, and environmental damage, leading to fewer replacements and lower maintenance costs.

Versatility

A single material handling hose can often be used across multiple applications, making it a flexible solution for various industrial needs.

Types of Material Handling Hose

Different applications require different hose constructions. Below are the most common types of material handling hose.

Rubber Material Handling Hose

Rubber hoses are known for their flexibility and abrasion resistance. They are ideal for heavy-duty applications involving sand, cement, and gravel.

PVC Material Handling Hose

PVC material handling hose options are lightweight and cost-effective, making them suitable for less abrasive materials and lower pressure applications.

Polyurethane Material Handling Hose

Polyurethane hoses offer excellent abrasion resistance and transparency, allowing operators to visually monitor material flow.

Composite Material Handling Hose

Composite hoses are layered with multiple materials to provide chemical resistance, strength, and flexibility for specialized industrial use.

Factors to Consider When Choosing a Material Handling Hose

Selecting the right material handling hose requires careful evaluation of your operational needs.

Material Type

Consider whether you are transferring abrasive solids, powders, liquids, or corrosive substances.

Pressure and Vacuum Ratings

Ensure the material handling hose can withstand the operating pressure or vacuum conditions of your system.

Temperature Range

Some materials require hoses that can handle extreme heat or cold without cracking or losing flexibility.

Flexibility and Bend Radius

A flexible material handling hose improves maneuverability and reduces stress on connections.

Compliance and Standards

Certain industries require hoses that meet specific safety or hygiene standards, particularly in food and pharmaceutical applications.

Maintenance Tips for Material Handling Hose

Proper maintenance extends the lifespan of your material handling hose and ensures optimal performance.

- Inspect hoses regularly for signs of wear, cracks, or leaks

- Clean the interior to prevent material buildup

- Store hoses in a dry, shaded area when not in use

- Avoid exceeding pressure or temperature limits

Routine checks help prevent unexpected failures and costly downtime.

Why Material Handling Hose Matters in Modern Industry

In today’s fast-paced industrial environment, reliable material transfer systems are essential. A high-quality material handling hose not only improves efficiency but also enhances safety and reduces operational risks. By investing in the right hose and maintaining it properly, businesses can ensure smoother workflows and long-term cost savings.

Conclusion

A material handling hose is a critical component in industries that rely on efficient and safe material transfer. Understanding the different types, applications, and selection factors helps ensure optimal performance and durability. Whether used in manufacturing, construction, agriculture, or food processing, the right material handling hose contributes directly to productivity, safety, and operational success.

By choosing wisely and maintaining your hose systems properly, you can significantly improve your material handling operations while minimizing downtime and maintenance costs.