PCB Prototype Assembly: How FastTurn PCB Simplifies Your Prototyping Needs

Introduction

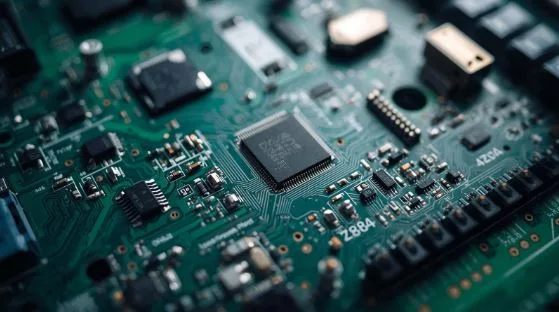

In the world of electronics, the need for efficient and reliable PCB prototype assembly is crucial for successful product development. Whether you’re designing a new gadget or refining an existing product, having a high-quality PCB (printed circuit board) is essential for functionality. FastTurn PCB is a leader in offering PCB prototype assembly services, ensuring your prototypes are built with precision and delivered quickly.

This article will delve into the importance of PCB prototype assembly, the benefits of using services like FastTurn PCB, and how to choose the best provider for your needs. With detailed insights, we’ll guide you on how FastTurn PCB can make your next project a success.

What is PCB Prototype Assembly?

Definition of PCB Prototype Assembly

A PCB prototype assembly involves creating a prototype printed circuit board (PCB) by placing and soldering electronic components on a PCB. This step is a vital part of the development process, allowing designers and engineers to test and verify the functionality of the circuit before full-scale production begins.

The Role of Prototype PCB Assembly in Electronics Development

Prototype PCBs are used to validate the design of a new product. During this phase, engineers test the PCB for design errors, functionality, and integration with other components. These prototypes are often used for testing, troubleshooting, and debugging purposes, ensuring that the final product will perform optimally once it’s mass-produced.

FastTurn PCB specializes in offering PCB prototype assembly services, allowing businesses to move from concept to testing in a fraction of the time, all while ensuring precision and quality.

Why Choose FastTurn PCB for Your Prototype Assembly Needs?

1. Speed and Efficiency

FastTurn PCB offers one of the quickest turnaround times in the industry. Their rapid prototype assembly service allows businesses to move from design to testing without delays, making it easier to meet tight deadlines.

2. High-Quality Standards

FastTurn PCB prides itself on using only the highest quality materials for PCB manufacturing and assembly. Their quality control processes ensure that every PCB meets the required standards, reducing the chances of costly mistakes during mass production.

3. Affordable Solutions

Unlike many high-end PCB manufacturers, FastTurn PCB offers competitive pricing without compromising on quality. Their solutions are perfect for businesses that need high-quality PCBs but are also mindful of their budget.

4. Turnkey PCB Assembly

With FastTurn PCB’s turnkey services, you don’t need to worry about sourcing components separately. They handle everything from sourcing components to final assembly, testing, and delivery. This saves you time and resources, allowing you to focus on other aspects of your project.

5. Wide Range of PCB Types

FastTurn PCB handles various types of PCBs, including rigid, flexible, and high-frequency PCBs. They also specialize in custom PCBs tailored to your specific project needs, ensuring a perfect fit for your application.

How to Use PCB Prototype Assembly Services

Steps to Utilize FastTurn PCB’s Prototype Assembly Services

- Design Your PCB:

First, create your PCB design using CAD (Computer-Aided Design) software. Ensure that your design follows standard guidelines for layout and component placement. - Submit Your Design Files:

Once your design is complete, submit your Gerber files and Bill of Materials (BOM) to FastTurn PCB. These files are essential for them to create your PCB prototype. - Prototype Production:

FastTurn PCB will fabricate your prototype based on your design files. They will ensure that the quality of the components and the board meets the required standards. - Assembly and Testing:

After fabricating the prototype, FastTurn PCB will proceed with assembling the components onto the PCB. Once assembled, they will run functional tests to ensure everything works as expected. - Final Delivery:

After testing and final checks, your prototype PCB is shipped to your location. This process typically takes a few days depending on the complexity of the design.

Benefits of PCB Prototype Assembly

1. Cost-Effective Development

Creating PCB prototypes helps you identify design flaws early, saving you money by avoiding the production of faulty mass-produced boards.

2. Improved Product Quality

Prototype assembly allows you to test the design’s functionality in real-world conditions, ensuring the product’s quality before mass production.

3. Faster Time to Market

By using services like FastTurn PCB, you can speed up the development process, getting your product to market faster.

4. Flexibility

With prototype assembly, you have the flexibility to make changes to your design during the testing phase. This allows for rapid iteration and improvement before final production.

Common Mistakes to Avoid in PCB Prototype Assembly

1. Overlooking Testing and Validation

Failing to conduct proper testing on your PCB prototype can lead to undetected issues, which might only surface during the mass production phase.

2. Ignoring Design Rules

It’s essential to follow design rules and guidelines when creating a PCB prototype. Skipping these can result in manufacturing defects, leading to costly revisions.

3. Choosing the Wrong Assembly Partner

Not all PCB manufacturers are equal. Some may not offer the quality or expertise you need. That’s why partnering with a trusted name like FastTurn PCB is important for ensuring success.

Tips for Choosing the Right PCB Prototype Assembly Provider

1. Check Experience and Expertise

Look for a provider like FastTurn PCB with extensive experience in PCB fabrication and assembly. The more experience they have, the better they’ll be at handling complex designs.

2. Evaluate Their Turnaround Times

For quick product launches, choose a provider with a reputation for fast turnaround. FastTurn PCB’s rapid production service ensures your PCB prototypes are ready in no time.

3. Quality Control Processes

Ensure the provider follows strict quality control measures. FastTurn PCB’s attention to detail ensures the highest quality of assembly, reducing the likelihood of defects in your prototypes.

Conclusion

PCB prototype assembly is a crucial part of the electronics development process. By working with a reliable provider like FastTurn PCB, you can ensure that your prototypes are assembled quickly, efficiently, and at a high level of quality. Whether you’re developing a new product or refining an existing design, FastTurn PCB can help you meet your goals without unnecessary delays or costs.

FAQs

1. What is PCB prototype assembly?

PCB prototype assembly is the process of creating a prototype printed circuit board (PCB) by assembling components onto the board for testing before mass production.

2. Why is FastTurn PCB a good choice for prototype assembly?

FastTurn PCB offers quick turnaround times, high-quality materials, affordable pricing, and turnkey solutions, making them an excellent choice for PCB prototype assembly.

3. How long does it take to get a PCB prototype from FastTurn PCB?

Depending on the complexity of your design, FastTurn PCB can deliver your prototype in as little as 24-72 hours.

4. Can FastTurn PCB handle custom PCB designs?

Yes, FastTurn PCB specializes in custom PCBs, allowing you to tailor your prototypes to meet the specific needs of your project.

5. What types of PCBs can FastTurn PCB assemble?

FastTurn PCB offers services for rigid, flexible, high-frequency, and rigid-flex PCBs, ensuring that your project’s needs are met.