Quality Guillotine Shear Accessories for Industrial Metalworking

In the fast-paced world of industrial metalworking, precision, efficiency, and reliability are paramount. Guillotine shears play a critical role in cutting and shaping metal sheets, offering speed and accuracy for a variety of applications. However, the performance and longevity of these machines heavily depend on the quality of their components. High-quality guillotine parts and accessories are essential to maintain optimal function, ensure safety, and reduce downtime in industrial operations.

Understanding the Role of Guillotine Shears

A guillotine shear is a mechanical device designed to cut metal sheets and plates into specific sizes. It is commonly used in industries such as automotive, aerospace, construction, and manufacturing, where consistent precision is required. Unlike other cutting tools, guillotine shears rely on a straight blade motion, making them ideal for straight cuts on large sheets of metal.

The efficiency of a guillotine shear is not solely determined by the machine itself. The accessories and guillotine parts—including blades, hold-downs, back gauges, and hydraulic systems—play a critical role in ensuring consistent performance and accurate results.

Importance of High-Quality Guillotine Parts

Investing in high-quality guillotine parts is crucial for industrial operations. These parts are subjected to constant wear and tear during metal cutting, which can affect the shear’s accuracy and productivity. Using inferior or worn-out components can lead to several issues, such as:

- Reduced cutting precision

- Increased material wastage

- Higher maintenance costs

- Potential safety hazards

High-quality components, on the other hand, ensure smooth operation, consistent cutting, and longer machine life. This makes them a cost-effective solution in the long term, minimizing unexpected downtime and improving overall efficiency.

Essential Guillotine Shear Accessories

A guillotine shear relies on various accessories to function effectively. Each accessory contributes to the machine’s performance and safety, ensuring high-quality cuts and efficient metalworking processes. Here are some key guillotine parts and accessories:

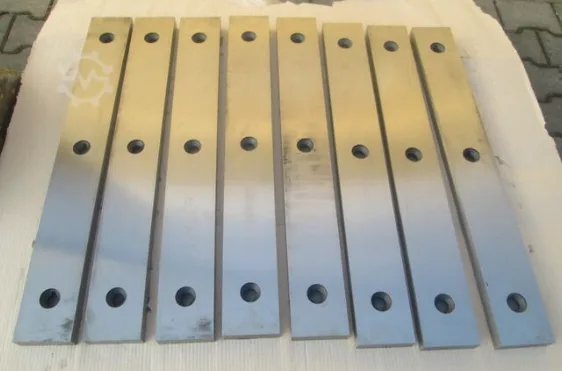

1. Cutting Blades

Cutting blades are the heart of a guillotine shear. They must be sharp, durable, and resistant to wear. High-quality blades are typically made from hardened steel and can maintain their cutting edge over extended periods. Properly maintained blades reduce metal deformation, produce cleaner cuts, and increase operational efficiency.

2. Hold-Downs

Hold-downs are critical for securing metal sheets during the cutting process. They prevent slippage and vibration, ensuring a precise and smooth cut. Adjustable hold-downs allow operators to accommodate various material thicknesses and types, improving the shear’s versatility.

3. Back Gauges

Back gauges are used to measure and position the metal sheet accurately before cutting. They ensure consistent and repeatable cuts, which is vital in high-volume production environments. Quality back gauges are durable, easy to adjust, and compatible with automated systems for enhanced efficiency.

4. Hydraulic Systems

Modern guillotine shears often rely on hydraulic systems to power the cutting action. High-quality hydraulic pumps, cylinders, and valves ensure smooth blade movement, consistent cutting force, and reduced wear on mechanical components. Reliable hydraulics also minimize maintenance needs and increase machine lifespan.

5. Safety Guards and Sensors

Safety accessories are crucial in industrial metalworking. Guards and sensors protect operators from potential injuries by restricting access to moving parts during operation. High-quality safety components comply with industrial standards and enhance workplace safety.

Benefits of Upgrading Guillotine Shear Accessories

Upgrading to premium guillotine parts and accessories offers several benefits to metalworking operations:

Enhanced Cutting Precision

Using well-engineered blades, back gauges, and hold-downs ensures precise cuts every time. This is essential for industries that require high tolerance levels and minimal material wastage.

Increased Productivity

Efficient guillotine parts reduce machine downtime and minimize manual adjustments, allowing for faster operations and higher throughput. Upgraded components also handle higher workloads, supporting industrial-scale production.

Longer Machine Life

Quality accessories reduce wear on the machine’s core components, extending the lifespan of the guillotine shear. Consistent maintenance and timely replacement of key parts prevent costly repairs and improve return on investment.

Improved Safety

High-quality safety accessories, including guards, sensors, and emergency stops, protect operators from accidents. Maintaining proper safety standards is not only a legal requirement but also essential for employee confidence and morale.

Choosing the Right Guillotine Parts

Selecting the right guillotine parts is critical for maximizing performance and safety. Consider the following factors when choosing replacement or upgraded components:

- Compatibility: Ensure the accessories are compatible with your specific guillotine shear model. Universal parts may not provide the same level of performance or fit.

- Material Quality: Look for parts made from durable materials such as hardened steel or industrial-grade alloys, which can withstand heavy usage.

- Precision Engineering: Components that are precisely manufactured offer better alignment, smoother operation, and longer service life.

- Manufacturer Reputation: Choose parts from reputable suppliers known for consistent quality and reliability. This minimizes the risk of defects and performance issues.

- Maintenance Support: Access to technical support and spare parts ensures that your guillotine shear remains operational and efficient over time.

Maintaining Guillotine Shear Accessories

Regular maintenance is essential to keep guillotine shears performing at their best. Key maintenance practices include:

- Blade Sharpening: Regularly inspect and sharpen cutting blades to maintain clean, accurate cuts.

- Lubrication: Apply proper lubrication to moving parts and hydraulic systems to reduce friction and wear.

- Inspection: Check hold-downs, back gauges, and safety accessories for signs of damage or misalignment.

- Cleaning: Keep the machine free from metal debris, dust, and oil buildup, which can affect performance.

- Replacement: Replace worn or damaged components promptly to avoid compromising cutting precision and safety.

Following these maintenance practices extends the lifespan of guillotine parts and ensures consistent performance in demanding industrial environments.

Trends in Guillotine Shear Accessories

The metalworking industry is constantly evolving, and guillotine shear accessories are no exception. Recent trends include:

- Automation Integration: Modern guillotine shears are increasingly equipped with automated back gauges and digital controls for higher precision and reduced operator intervention.

- Enhanced Safety Features: Advanced sensors and safety interlocks improve workplace protection and compliance with industrial standards.

- Lightweight Materials: New alloys and composite materials are being used in blades and structural components to reduce weight while maintaining strength.

- Energy Efficiency: Hydraulic systems and motor components are being optimized to reduce energy consumption and operational costs.

These innovations highlight the importance of investing in quality guillotine parts to stay competitive in industrial metalworking.

Conclusion: Invest in Quality for Optimal Performance

Guillotine shears are indispensable tools in modern metalworking, but their performance and longevity depend heavily on the quality of their components. High-quality guillotine parts and accessories—from blades and hold-downs to back gauges and hydraulic systems—ensure precise cutting, enhanced productivity, and improved safety.

Investing in premium components not only boosts efficiency but also extends the life of your machinery, reduces maintenance costs, and safeguards operators. As the industry continues to embrace automation and advanced manufacturing techniques, quality guillotine shear accessories remain a critical element of industrial success.

For metalworking operations aiming for precision, reliability, and safety, upgrading to high-quality guillotine parts is not just an option—it’s a strategic necessity. Prioritize quality accessories today and ensure your guillotine shear performs at its peak for years to come.