Reliable Lithium Battery Systems for AGV and AMR Automation Solutions

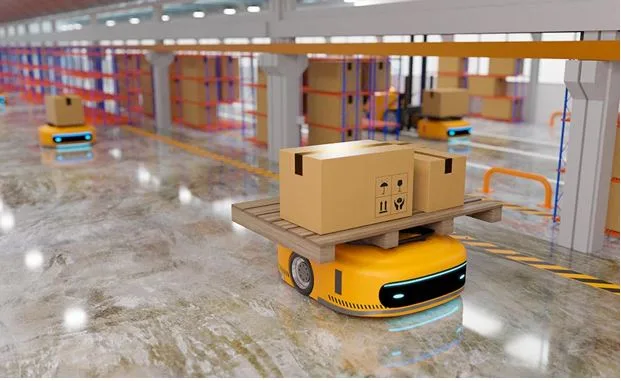

As industries around the world accelerate their adoption of smart automation technologies, Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) have become critical tools for streamlining material handling, warehouse management, and industrial logistics. At the heart of these autonomous systems lies a vital component that determines performance, uptime, and operational efficiency—the battery system. With lithium-ion technology leading the charge, businesses now depend on reliable lithium battery systems to power the future of automation.

For any operation seeking to maximize productivity and minimize downtime, choosing the right batteries for agv and AMR platforms is not just a technical decision—it’s a strategic advantage.

The Role of Battery Technology in Industrial Automation

AGVs and AMRs are designed to operate continuously, navigating warehouses, production floors, and distribution centers with precision and intelligence. These systems rely on battery power to execute tasks such as material transport, inventory handling, pallet movement, and route optimization.

In this high-demand environment, battery performance directly impacts:

- Uptime and Productivity: Longer-lasting batteries reduce the need for frequent recharging or swaps.

- Safety and Reliability: Stable voltage output and thermal control minimize the risk of overheating or failure.

- Energy Efficiency: Advanced battery management systems (BMS) improve charge cycles and reduce energy waste.

- Space Utilization: Compact batteries allow for more agile and efficient robot designs.

Hence, reliable lithium battery systems are the preferred choice for powering AGVs and AMRs, offering enhanced performance, safety, and energy efficiency over traditional lead-acid batteries.

Why Lithium-Ion Batteries Lead the Way

Among the various battery chemistries available, lithium-ion has emerged as the gold standard for industrial automation, especially in mobile robotics. Here’s why lithium-ion is considered the best option when it comes to batteries for AGV and AMR systems:

- High Energy Density

Lithium-ion batteries offer significantly higher energy density compared to older technologies. This means they can store more energy in a smaller footprint—ideal for compact AGV and AMR designs.

- Fast Charging Capability

One of the key advantages of lithium batteries is their rapid recharge time. Some systems support opportunity charging, allowing AGVs to top up power during idle moments—minimizing downtime and maintaining continuous operations.

- Longer Cycle Life

A well-designed lithium battery system can deliver up to 2,000–5,000 charge cycles, depending on usage and conditions. This longevity reduces replacement frequency, translating into lower total cost of ownership (TCO).

- Maintenance-Free Operation

Unlike lead-acid batteries, which require regular water topping and equalization, lithium batteries are virtually maintenance-free, freeing your team from unnecessary manual interventions.

- Integrated Battery Management System (BMS)

Every lithium battery system for AGV and AMR platforms comes with a BMS that monitors temperature, voltage, current, and state of charge—ensuring safe and optimal performance at all times.

Key Features of Reliable Lithium Battery Systems for AGVs and AMRs

Choosing the right battery system for your automation needs goes beyond chemistry. It requires a holistic approach that includes engineering, safety, software, and integration. The most reliable lithium battery systems offer the following key features:

- Modular Design

Scalability is crucial for growing operations. Modular battery packs allow for flexible configurations that adapt to different robot models, use cases, and operational intensities.

- Smart Battery Management System

An intelligent BMS not only protects the battery but also communicates with the AGV/AMR’s central controller, sharing real-time data on state of charge, cycle count, fault detection, and temperature. This integration helps schedule efficient charging cycles and avoid unexpected power drops.

- Robust Safety Mechanisms

Reliable batteries feature multiple layers of safety, including overcharge protection, short-circuit prevention, thermal cutoffs, and pressure release valves—ensuring safe operation even under extreme industrial conditions.

- Industrial-Grade Durability

AGVs and AMRs operate in harsh environments—extreme temperatures, vibrations, and dust. Battery systems designed for industrial use are rugged, sealed, and certified to withstand such demanding conditions.

- Custom Engineering for Performance

Industry leaders in custom batteries for AGV applications offer tailored voltage, capacity, and form factor solutions that align perfectly with the robot’s performance specs and operational timelines.

Applications Across Industry Sectors

Reliable lithium battery systems for AGVs and AMRs are essential across a wide range of industries, each with its own unique demands:

- E-commerce & Retail: Automated warehouse robots need lightweight, fast-charging batteries to fulfill high-speed order picking and delivery.

- Manufacturing: AGVs in factories depend on reliable power to transport raw materials, parts, and finished goods across workstations.

- Pharmaceutical & Medical: AMRs used in cleanrooms and labs require low-emission, maintenance-free battery systems with precise energy output.

- Automotive: Logistics and assembly-line automation rely heavily on high-capacity batteries for uninterrupted material handling.

- Food & Beverage: Cold storage AGVs need batteries that perform reliably at sub-zero temperatures.

In all these cases, the quality and reliability of the battery system are key to the success of automated logistics and operational efficiency.

The Impact on Operational Efficiency

When operations run 24/7, even small improvements in uptime and energy efficiency can lead to significant ROI. Companies that adopt premium batteries for AGV platforms report:

- Up to 30% longer operational time per charge

- 50% reduction in charging time

- Significant cut in maintenance costs

- Fewer system errors and downtime related to battery failures

- Higher employee and machine productivity

In the long term, the right lithium battery system not only saves money but also increases competitiveness by keeping supply chains agile and reliable.

Sustainability and Environmental Benefits

Modern supply chains are under pressure to reduce their carbon footprints. Lithium-ion battery systems support sustainability goals by:

- Offering higher energy efficiency than traditional batteries

- Requiring fewer replacements over time

- Producing less heat and emissions

- Being recyclable through dedicated battery recycling programs

Businesses aiming to align with ESG (Environmental, Social, and Governance) objectives can greatly benefit from switching to eco-friendly lithium battery solutions.

Selecting the Right Lithium Battery Provider

To truly reap the benefits of automation, it’s critical to partner with a provider that understands the intricacies of both battery technology and industrial automation. When selecting a vendor for batteries for AGV, look for:

- Experience with AGV/AMR integrations

- In-house engineering and testing capabilities

- Customized solutions tailored to your needs

- After-sales support and service

- Certifications such as UL, CE, and ISO 9001

Your provider should act as a long-term partner—not just a supplier—offering insights, support, and innovation that keep your automation systems running flawlessly.

Future Trends in AGV and AMR Battery Technology

The world of lithium batteries is constantly evolving. Some exciting trends shaping the future of batteries for AGV and AMR systems include:

- Solid-State Batteries: Offering even higher energy densities, increased safety, and faster charging.

- Wireless Charging: Enabling AGVs to charge automatically while idle or during route pauses.

- AI-Powered Energy Management: Predictive algorithms to optimize charging schedules and extend battery life.

- Green Manufacturing: Eco-friendly production processes and recyclable battery components.

Staying ahead of these trends ensures your business continues to operate at the leading edge of automation and energy management.

Conclusion

As the backbone of AGV and AMR performance, reliable lithium battery systems are critical to achieving the goals of industrial automation: greater efficiency, lower costs, and higher safety. With advancements in lithium-ion technology, smart battery management, and rugged designs tailored for industrial use, businesses can now equip their fleets with long-lasting, high-performance power solutions.

Choosing the right batteries for AGV and AMR applications isn’t just about meeting energy needs—it’s about empowering your automation strategy with intelligent, sustainable, and future-ready energy.

If you’re looking to optimize your automation ecosystem, start with the power behind the performance—choose lithium batteries built for reliability and innovation.