The Role of Air-Cooled Laser Welders in On-the-Go Manufacturing

Manufacturing doesn’t stand still. As industries evolve, so do the expectations placed on the tools that power them. Companies today want equipment that isn’t just precise but also flexible and portable enough to adapt to changing work environments. Think of technicians repairing large equipment in the field, small workshops with limited floor space, or contractors juggling projects across multiple sites. In all these cases, lugging around bulky, water-cooled welders with external chillers can feel more like a burden than a solution.

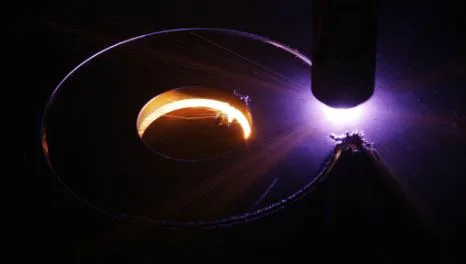

This is exactly where the air cooled laser welding machine earns its spotlight. By removing water tanks, chillers, and complex coolant systems, these compact machines deliver mobility and reliability without sacrificing performance for everyday welding tasks. For businesses that value flexibility, cost efficiency, and quick turnaround times, they’re increasingly becoming the smart choice.

Compact & Lightweight Design

One of the standout advantages of an air-cooled system is its compact form factor. Traditional water-cooled units often require heavy cooling tanks, pumps, and a mess of tubing that eats up valuable space. In contrast, air-cooled welders rely on fans and heat sinks to dissipate heat, which makes the overall footprint much smaller.

Imagine a small fabrication shop in a city center where every square foot of workspace is accounted for. Instead of dedicating an entire corner to a chiller setup, operators can tuck an air-cooled unit neatly against the wall or even wheel it to different stations as needed.

Practical benefits include:

- Space efficiency: No external chiller or reservoir needed.

- Lightweight build: Easier to move or reposition without special equipment.

- Workshop versatility: Can be integrated even into compact or mobile setups.

The result is not just saved space but also improved workflow efficiency—operators aren’t navigating around hoses, tanks, or extra equipment just to get the job done.

Superior Portability & On-Site Flexibility

Portability is more than just a buzzword here—it’s the defining strength of the air cooled laser welding machine. Field technicians often work in environments where transporting heavy, water-cooled systems isn’t realistic. Think of ship repair crews, aerospace teams working on fuselages, or even contractors handling on-site construction tasks.

With an air-cooled design, the machine is light enough to move with a simple hand truck, and in some cases compact enough to fit in the back of a van or truck bed. This makes it possible to take precision welding out of the factory and directly to the field.

Advantages at a glance:

- Transport-friendly: Easy to load, unload, and relocate between job sites.

- Flexible positioning: Can be used in awkward spaces where a bulky system wouldn’t fit.

- Handheld support: Many units pair with ergonomic handheld torches, further boosting mobility.

In industries where time is money, being able to bring the welder to the job instead of dragging the job back to the workshop is a huge competitive edge.

Simplified Setup & Maintenance

Let’s be honest—maintenance is one of those hidden costs that can quietly eat away at a company’s bottom line. Water-cooled systems require a constant eye on coolant levels, regular replacement, descaling treatments, and monitoring for leaks or bacterial growth. Skip those steps and you risk downtime—or worse, expensive repairs.

Air-cooled machines strip away that complexity. Most are designed as plug-and-play systems: set them down, connect power, and you’re ready to weld. Maintenance usually boils down to keeping the fans clear of dust and occasionally checking for blockages.

Typical maintenance checklist looks like this:

- Keep ventilation grills clean and unobstructed.

- Inspect the cooling fans for dust buildup.

- Run standard system checks before operation.

That’s it—no coolant, no pumps, no risk of freezing in cold environments. For operators, this means less downtime and more focus on actual welding.

Cost Savings & Energy Efficiency

Beyond convenience, cost savings are a major driver of adoption. An air cooled laser welding machine avoids the need for chillers, pumps, and plumbing accessories—bringing down the initial investment right from the start.

Then there’s the ongoing operational savings. Air cooling requires less power compared to running water pumps and maintaining chilled systems, making these machines naturally more energy-efficient.

Here’s a quick comparison:

| Feature | Air-Cooled | Water-Cooled |

| Initial Cost | Lower (fewer components) | Higher (requires chillers & accessories) |

| Maintenance | Minimal (fan cleaning) | Higher (coolant replacement, scaling) |

| Energy Use | Lower | Higher |

| Downtime Risk | Low | Moderate to High |

Add to this the fact that water-based systems often face issues like algae growth, scaling in pipes, or damage in freezing climates, and it’s clear why many workshops find air-cooled solutions to be more reliable and affordable in the long run.

Performance & Duty Considerations

Of course, it’s important to note that air-cooled systems are not a one-size-fits-all solution. They excel in low to medium power welding applications, where precision and portability matter more than sheer, continuous output.

Thanks to advances in fan design, heat-sink engineering, and smart power management, modern units can still handle extended duty cycles without overheating. For small to medium fabrication projects, metal repairs, and mobile applications, they’re more than capable.

That said, if your work involves round-the-clock, high-power production, a water-cooled system may still be better suited. The good news? Many companies now keep both on hand—water-cooled for heavy-duty continuous production, and air-cooled for flexible field or workshop use.

Real-World Applications

Where do air-cooled systems shine? Let’s take a look at a few practical use cases:

- Automotive repair: Perfect for precision welding on thin metals without dragging large equipment into crowded garages.

- Construction & field service: Portable enough to take to remote sites, reducing downtime.

- Small-scale workshops: Fits easily into limited space while offering professional-grade results.

- Maintenance teams: Ideal for quick on-site fixes, whether in factories, ports, or hangars.

As manufacturers look to digitize and automate further, these innovations — championed by forward-thinking providers like Denaliweld — position laser welding as a central pillar of smart manufacturing.

Conclusion

In today’s fast-paced manufacturing landscape, equipment that saves space, reduces costs, and adapts to changing work environments is more valuable than ever. An air cooled laser welding machine brings together portability, simplicity, and reliability in one compact package.

For small workshops, mobile technicians, and operators looking to cut down on maintenance headaches, the benefits are clear: less setup, fewer consumables, and more time actually welding. While water-cooled machines still hold their place in high-power, continuous production, air-cooled systems have carved out a niche that’s hard to ignore.

If you’re exploring options, take a closer look at our air cooled laser welding machine. Designed for today’s demands, it delivers the portability and efficiency modern welders need—without the extra weight of traditional cooling systems.