The Role of Used Test Equipment in Industrial Testing and Quality Control

Test equipment plays an essential role in industrial operations by supporting the safe and reliable performance of machinery and processes. Accurate measurement allows issues to be detected early, reducing downtime and preventing costly failures. Test equipment also helps organizations comply with industry standards and regulatory requirements. Through continuous monitoring, companies can improve efficiency, minimize waste, and extend the lifespan of their assets. Investing in suitable test equipment supports consistent performance and long-term operational improvement.

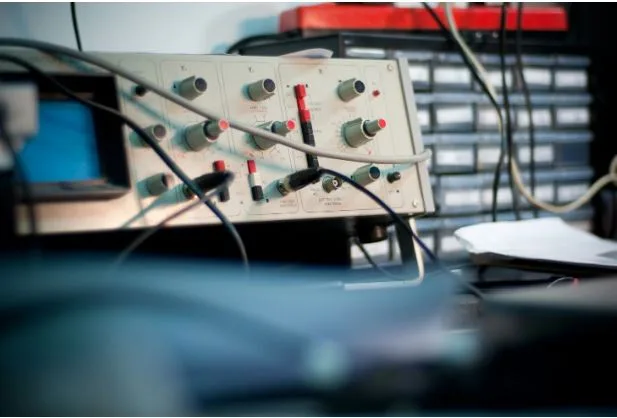

Overview of Used Test Equipment

Used test equipment refers to previously owned instruments designed to measure, inspect, or evaluate technical parameters across various applications. Common examples include oscilloscopes, multimeters, spectrum analyzers, and similar devices. Purchasing used equipment can provide access to dependable, high-quality instruments at a lower cost, including models that may no longer be available as new. However, buyers must carefully evaluate the condition, calibration status, and functionality to ensure the equipment meets accuracy and performance requirements.

New Versus Used Test Equipment

There are notable differences between new and used test equipment. New instruments typically offer the latest technology, manufacturer warranties, and predictable performance, but they come at a higher cost. Used equipment offers a more affordable alternative and is often available immediately. Potential limitations include outdated features, incomplete service histories, or reduced accuracy over time. Organizations must assess technical needs, budget constraints, and reliability expectations when choosing between new and used options.

Advantages and Limitations of Used Equipment

Used test equipment provides clear advantages, particularly cost savings, allowing businesses to acquire professional-grade tools without significant financial investment. Many refurbished instruments are sold by reputable suppliers and may include warranties or recalibration services. However, risks include hidden defects, limited compatibility with modern systems, or restricted support for older models. These factors should be carefully reviewed before making a purchase.

Industries Relying on Used Test Equipment

Used test equipment is widely used across multiple industries as a cost-effective solution for quality control and performance testing. Manufacturing facilities use it to verify product safety and consistency, while telecommunications companies rely on it for network testing and troubleshooting. In healthcare, calibrated instruments help validate the performance of diagnostic devices. The automotive industry uses test equipment for vehicle inspections, emissions testing, and system diagnostics. Across these sectors, used equipment supports operational efficiency while managing costs.

Industry-Specific Equipment Requirements

Each industry depends on specialized testing instruments suited to its operational demands. Manufacturing environments commonly use precision measurement tools such as gauges and calipers. Construction relies on heavy-duty testing equipment to assess material strength and structural integrity. Healthcare facilities depend on advanced diagnostic tools to support equipment validation and patient care. Selecting the correct type and quantity of test equipment is critical for maintaining accuracy, safety, and efficiency.

Factors Influencing Equipment Selection

Cost efficiency is a key factor when selecting test equipment. While new instruments offer advanced features and long-term support, used equipment provides financial flexibility. Decision-makers must consider frequency of use, maintenance requirements, and potential upgrade needs to balance performance with cost. A thorough evaluation helps ensure testing capabilities are maintained without unnecessary spending.

Availability and Market Value

The market for used test equipment has expanded, offering a wide range of instruments across technical fields. Increased availability allows organizations to acquire specialized tools at reduced prices, supporting capability upgrades without major capital investment. Additional benefits include lower depreciation and faster delivery compared to new equipment, making used instruments a practical option for many operations.

Environmental Considerations

Reusing and refurbishing test equipment contributes to environmental sustainability by reducing waste and conserving resources. Extending the service life of instruments lowers demand for new manufacturing, reduces energy consumption, and supports circular economy practices. These efforts help organizations reduce their environmental impact while maintaining operational performance.

Maintenance and Reliability Considerations

Maintenance requirements and reliability play a critical role in equipment selection. Instruments that require frequent servicing can increase downtime and operational costs. Reliable equipment minimizes disruptions and supports consistent productivity. Reviewing maintenance history, calibration records, and vendor support helps organizations select solutions that deliver dependable performance and long-term value.

Future Trends in Used Test Equipment

Industries are expected to increase their use of used test equipment due to rising costs and ongoing technological development. Advances in refurbishment and calibration processes are improving the reliability of pre-owned instruments. As a result, organizations are likely to adopt used equipment more widely while maintaining strict performance and compliance standards.

Emerging Sectors and Demand Growth

Emerging industries such as renewable energy, electric vehicles, and biotechnology are expected to drive growing demand for used test equipment. Renewable energy projects require reliable tools to verify system efficiency, while electric vehicle development depends on accurate battery and power system testing. Biotechnology also relies on specialized instruments, where refurbished equipment provides a cost-effective way to support research and innovation.

FAQs

What should buyers check before purchasing used test equipment?Buyers should review calibration records, service history, and overall condition. It is also important to confirm that the equipment meets current accuracy standards and is compatible with existing systems or software.

Is the used test equipment reliable for professional and industrial use?Used test equipment can be reliable when sourced from reputable suppliers and properly refurbished or calibrated. Many instruments remain accurate and dependable for years when maintained and used within specified limits.

Does the used test equipment meet industry standards and regulations?

Used test equipment can meet industry standards if it is properly calibrated and certified when required. Regular verification and maintenance are essential to ensure ongoing compliance and measurement accuracy.